So... this is my first post on these forums; and it's a long one.

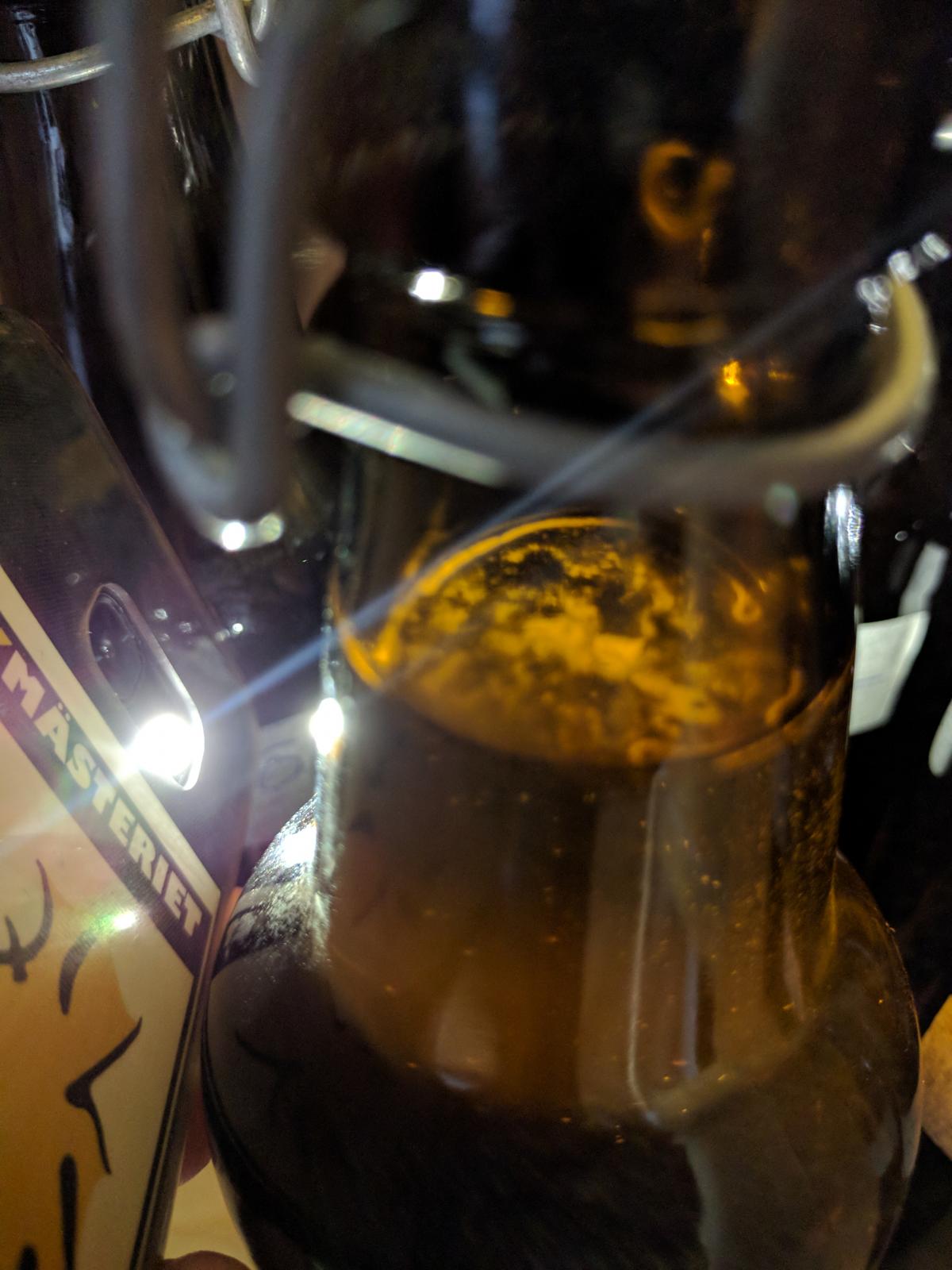

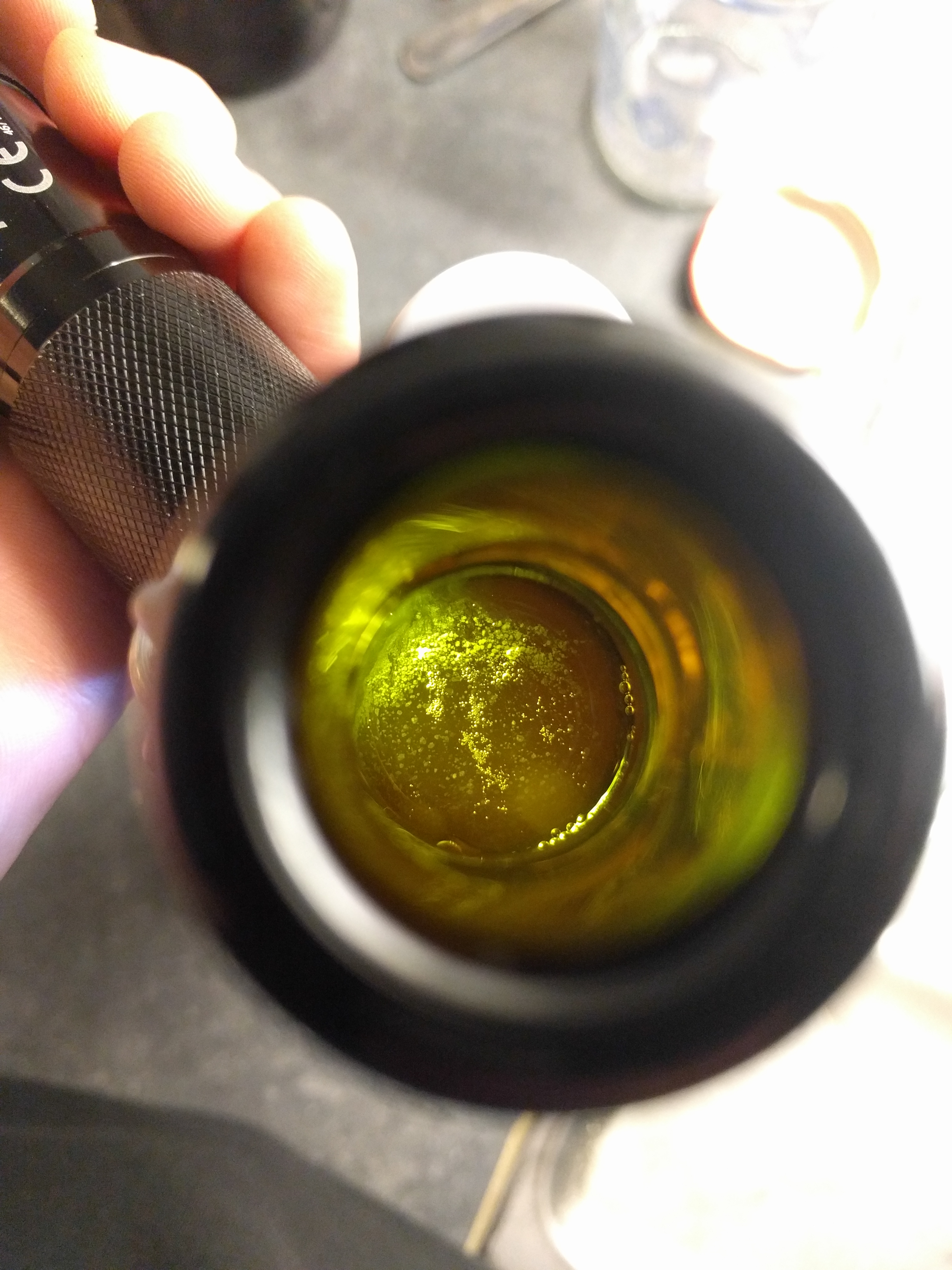

I have brewed about 12 batches since I got into homebrewing, and I have started noticing that I'm getting gushers; usually after a couple of months.

I can trace this back to the 5th batch I made, although I do believe that I saw "fermentation" rings in the bottles back in the third batch I made (which was a witbier). I first thought this was due to it using a funky belgian yeast (Mangrove jacks M21), and I did never have any gushers with that one (probably drank it before the gusher infection developed ).

).

So generally, this gusher infection is tasteless, but seems to consume all sugar it can get it hands on (the ones where I've used a Saison yeast generally don't have the problem to that extent due to the Saison yeast itself being able to partially digest dextrins).

So, what I am trying to do now is to find any processes where I might be doing something wrong, thus, where I could have (or continuously am) introducing wild yeasts (well, I believe it's a wild yeast, brett do indeed cause a "filmy ring", but the beer doesn't taste like "barn" or "horse-blanket"):

The possible causes for infection I can come up with would be:

Ohh, and I always use food grade plastic gloves during bottling and when pouring the wort to the secondary fermentation vessel.

So, can anyone see any other cause for infection? (or the validity in the causes of infection I could come up with)

I have brewed about 12 batches since I got into homebrewing, and I have started noticing that I'm getting gushers; usually after a couple of months.

I can trace this back to the 5th batch I made, although I do believe that I saw "fermentation" rings in the bottles back in the third batch I made (which was a witbier). I first thought this was due to it using a funky belgian yeast (Mangrove jacks M21), and I did never have any gushers with that one (probably drank it before the gusher infection developed

So generally, this gusher infection is tasteless, but seems to consume all sugar it can get it hands on (the ones where I've used a Saison yeast generally don't have the problem to that extent due to the Saison yeast itself being able to partially digest dextrins).

So, what I am trying to do now is to find any processes where I might be doing something wrong, thus, where I could have (or continuously am) introducing wild yeasts (well, I believe it's a wild yeast, brett do indeed cause a "filmy ring", but the beer doesn't taste like "barn" or "horse-blanket"):

- I brew the beer in a braumeister, should generally not be a cause for infections due to, well, it boils the wort, everything is hot enought to kill micro organisms. Also, I sterilize it with VWP every 5th brew or so (and I do of course clean in with a sponge, washing-up liquid etc. after each brew).

- Spraying the cooling spiral with Star San

- Cleaning my plastic fermentation buckets with VWP and Star San

- Using a "Double blast" bottle cleaner and washing up liquid for cleaning the bottles before putting them in the oven

- Sterilizing my bottles in the oven (175 degrees C) for an hour (previously 150c for 1.5 hours; not enough according to how to brew)

- Boiling any hoses I use + the flip-caps for the bottles (and star-saning the flip-caps during the bottling process)

The possible causes for infection I can come up with would be:

- Not letting the cooling spiral rest in the hot wort for long enough before turning on the cold water (having the hot wort acting as a sanitizer)

- Not cleaning the bottles properly enough (I have seen a white film in a few of them, even after cleaning). I will probably have to start using the dreaded bottle-cleaning brush. Although; shouldn't the heat of the oven take care of this?

- The vessels, when unused being stacked in each other, have caused them to get a few scratches inside; might hide some nasty wild yeasts

- My star san mixture was too weak during my first 7 or 8 batches

Ohh, and I always use food grade plastic gloves during bottling and when pouring the wort to the secondary fermentation vessel.

So, can anyone see any other cause for infection? (or the validity in the causes of infection I could come up with)