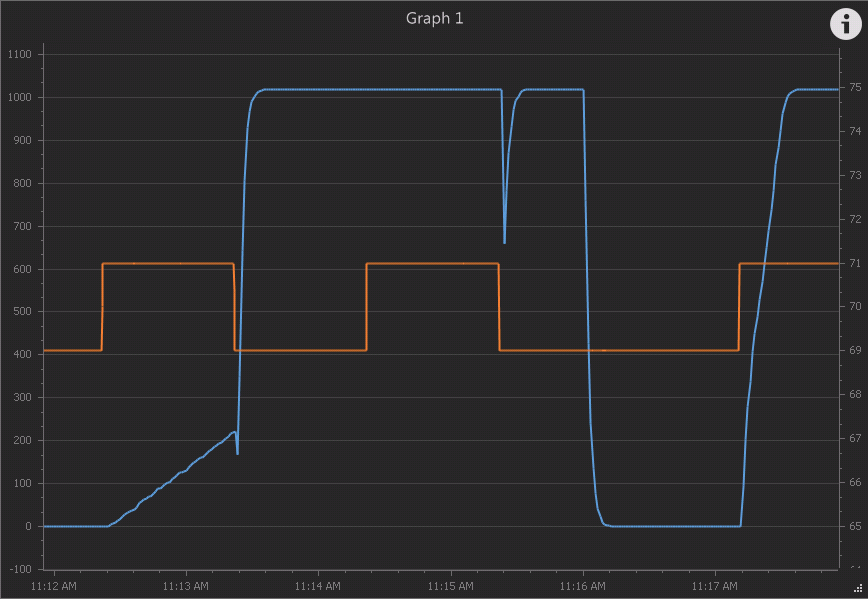

I understand tuning PIDs, this is just not acting as expected at the moment (I cannot check full closed loop with feedback right now, until I finish the panel electrics.) Here is a

thread on the stilldragon forum of me implementing this 4 years ago with the Sestos D1S-CR analog output PID, which has funky values, such as using t for the derivative.... so I know I have some work to do to understand the conversion from them to this.

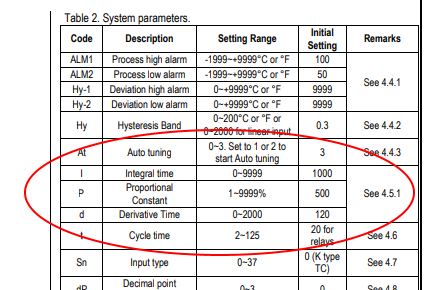

Sestos is close to auber, and here is an excerpt from The

Auber Instructions:

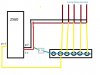

View attachment 601736

I understand sensor and valve placement, actually valve is not quite as critical(you stop flow in one place in the loop, you stop it everywhere), but sensor is very critical, similar to a RIMS controller requiring it be a close to and above the heater element as possible to measure temp changes quickly even with small flow. For a still reflux condenser, the best placement is a probe inserted right into the condenser, where the heat source is(condensing vapor), as this will read correctly no matter the flow...

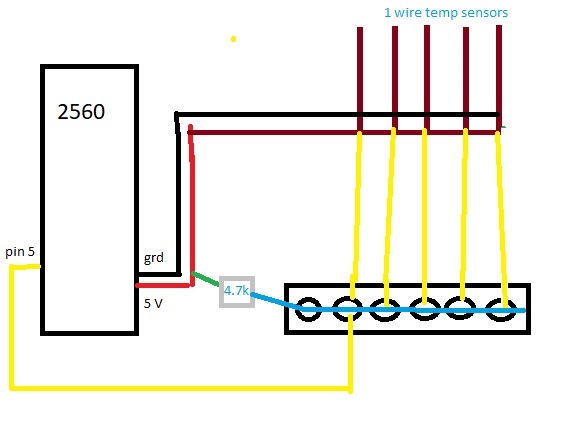

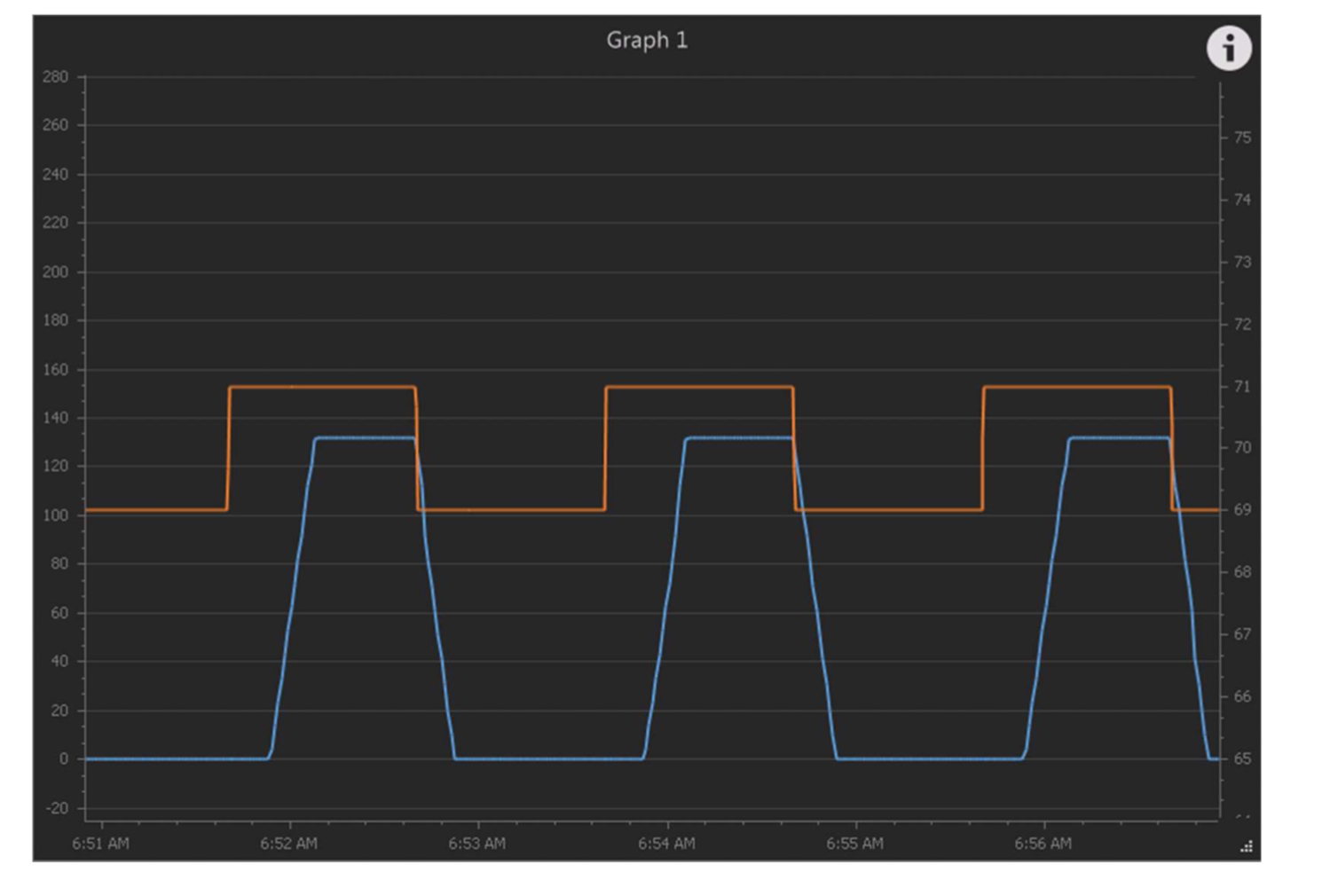

My issue is that the Kp,Ki,Kd are not acting as I expect them to, but it could be 100% my fault.. I expect that even with no feedback,(the temperature does not change, a condition that would also happen if you were using this for RIMS and either the SSR/heater was not connected/working or the temp prove was not inserted..) that:

- With a small Kp and even a tiny Ki, the output would increase over time to get to 100% output... it does not... it rises, then plateaus, which is similar to no integral component...

- Increasing or decreasing the Kd would flatten out the output and eliminate quick changes. it does not..

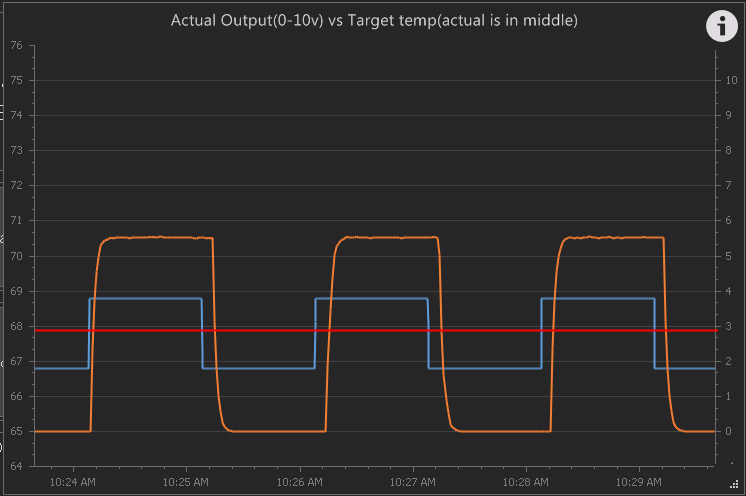

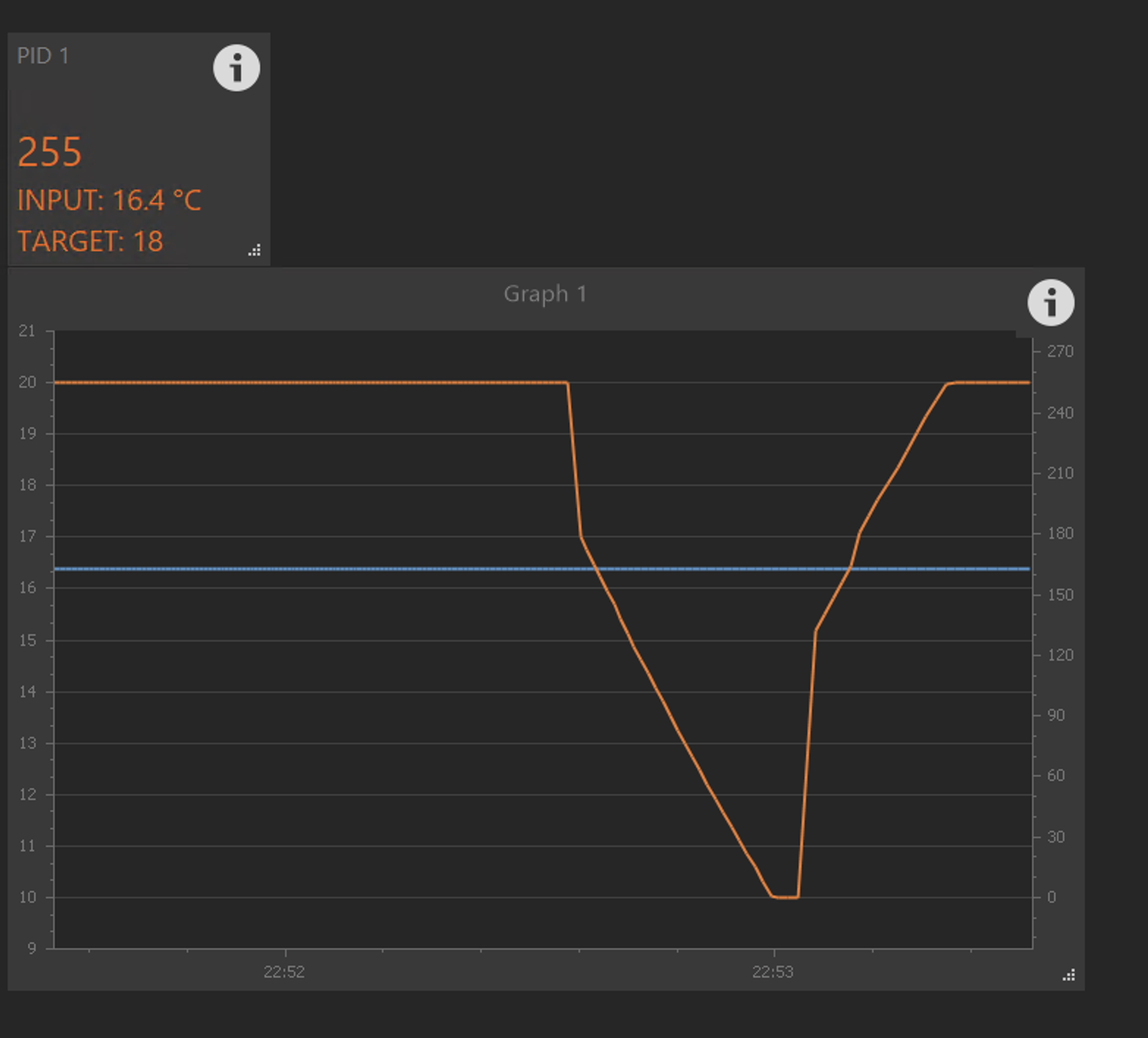

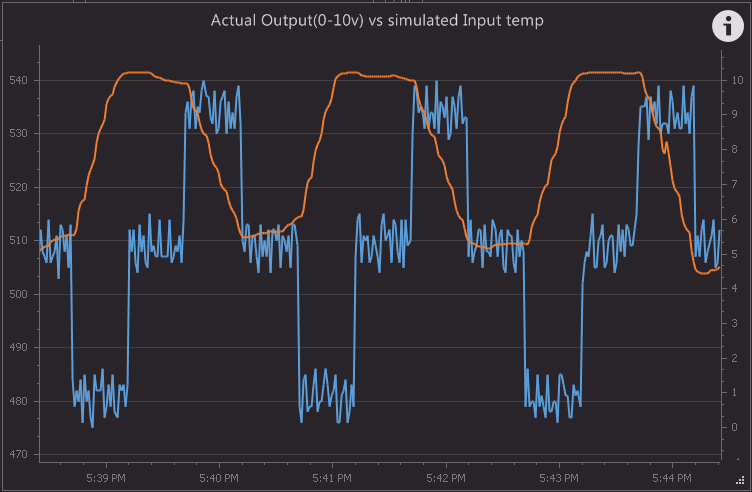

Here is a graph of the analog output measuring actual output of the 0-10v usign a 10k-10k voltage divider to the Mega(Orange line is 0-10V), and a script changes the target temp (Blue line is 66.8 to 68.8F swing) the actual temp is the red line (added by hand at 67.8F)

Changing Kp or Ki *do* change the amplitude of the output, but I *think* that any Kp and Ki value greater than zero should keep increasing and increasing the output over time to 100% output. Also, increasing the derivative should eliminate those sharp transitions... in reality, changing Kd does nothing that I can see... I think I should be able to get a sinusoidal output, but that ain't going to happen if I cannot smooth out the harsh changes.

View attachment 601745

I have to go to NC for holiday family visit for a week tomorrow, but will try to research how the Arduino MEGA actually implements the PID compared to a discrete PID controller...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)