dflipse

Active Member

I have a 3000W E-kettle. Faster heating is always nicer, and I wanted to obtain a more vigorous boil, so I picked up a roll of Reflectix and metal tape. Total cost was under $20 at Lowes.

Spent about an hour wrapping two layers around the various gadgets that stick out of my kettle.

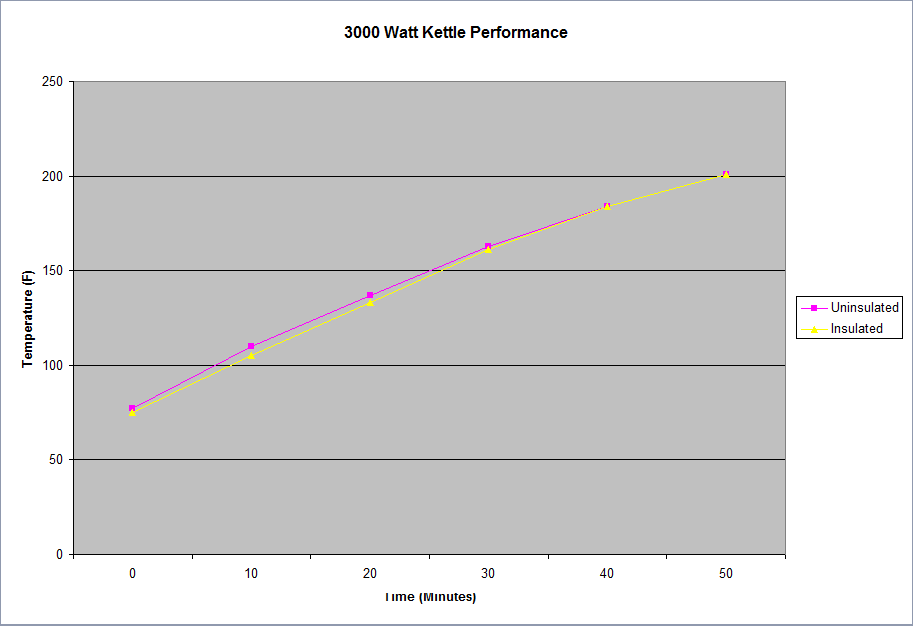

I was pretty happy with the aesthetics and assumed I would be with the performance. I did before and after testing of heating 5.8 gallons of tap water from room temperature to a boil. Here are the results-

Both kettles got to the full (just short of rolling) boil within 5 minutes after that last temperature reading.

If we were doing real science here, my error bars would be 5F (well, and I'd be using Kelvin, but that's a separate issue) which makes this a completely null result. No change demonstrated by the intervention.

I will say that the insulation is warm, but I can rest my hand on it. That was definitely not the case with the bare kettle. So I do believe that less heat is being radiated away, but it just must not be that big a deal. Evaporative cooling must be the major force for heat loss.

Now I need to decide if I want to just toss the insulation, or go on with my plan to get the whole thing coated in truck bed liner.

Spent about an hour wrapping two layers around the various gadgets that stick out of my kettle.

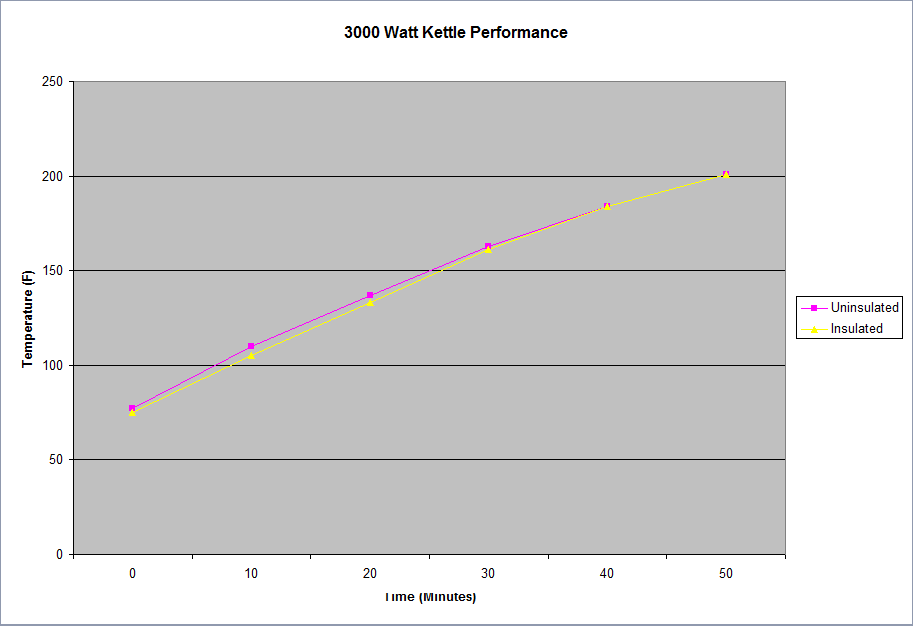

I was pretty happy with the aesthetics and assumed I would be with the performance. I did before and after testing of heating 5.8 gallons of tap water from room temperature to a boil. Here are the results-

Both kettles got to the full (just short of rolling) boil within 5 minutes after that last temperature reading.

If we were doing real science here, my error bars would be 5F (well, and I'd be using Kelvin, but that's a separate issue) which makes this a completely null result. No change demonstrated by the intervention.

I will say that the insulation is warm, but I can rest my hand on it. That was definitely not the case with the bare kettle. So I do believe that less heat is being radiated away, but it just must not be that big a deal. Evaporative cooling must be the major force for heat loss.

Now I need to decide if I want to just toss the insulation, or go on with my plan to get the whole thing coated in truck bed liner.

But can I get some more details on the tool box in the pic? Never mind I found it.

But can I get some more details on the tool box in the pic? Never mind I found it.