thatjonguy

Now with 57.93% more awesome!

Yes, yet another fermentation cabinet build.

I am building this one to be in an unheated (but insulated) garage during North Dakota winters where daytime highs can be -20s ambient.

For most of you it might be overkill. But why kill when you can overkill...

I haven't decided on the final size yet but it will be somewhere in the neighborhood of 4L x 5H x 4W. With a 3x4 door so I can wheel my Brewhemoth in and out.

Constructed of 2x4s and 1/4 inch moisture resistant plywood.

Insulated with R15 mineral wool in the walls and ceiling, floor will be extruded foam panels framed with treated 2x4s.

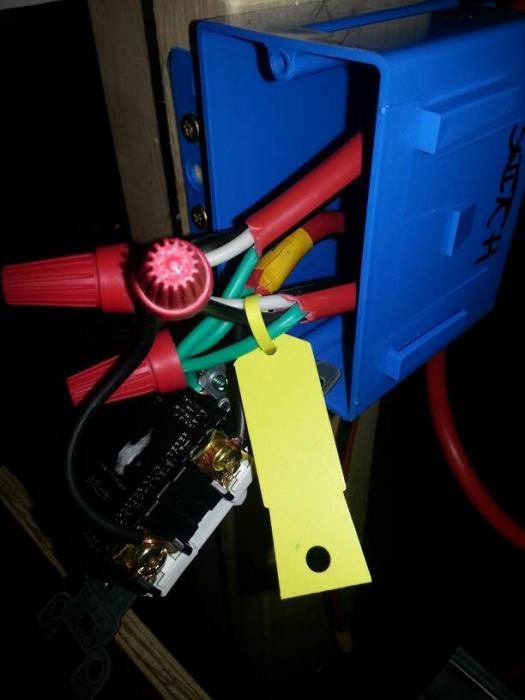

Run by a STC-1000 with 2 outlets (1 gang) for heat/cool.

It will also have a constant on outlet for a desk fan to circulate air.

A master switch on the exterior will control power to the unit.

All wired from a liberated 14/3 extension cord.

Cooling is a 5,000 BTU window air conditioner.

Heat will be provided by 200 watt personal heater (will it be enough? I am going to find out).

It will also have it's own CO2 supply for force carbing soda and soda water.

I am also thinking about a small shelf for carboys and bottle conditioning.

The top will be strong enough to hold empty buckets and carboys so I am making efficient use of the space in my garage.

I am going to start the floor and framing tonight. Pictures to follow.

I will post a materials list sometime soon. I am planning to knock it out while on paternity leave this week (after SWMBO and kids are in bed).

Materials List

(work in progress, framing (2x4) lumber is an estimate; I may need to add more to this)

Lumber:

10 - 2x4x10'

6 - 2x4x8'

6 - 1/4" plywood sheets (4x8)

1 - 1/2" plywood sheet (4x8)

2 - treated 4x4x8'

3 - 1x4X8' furring strips

6 to 10 - 1x4x8' common board or better for trim

2 - 1x6x8' common board or better for trim

Fasteners:

100 - #10x4" screws (I love GRK Mutlipurpose, no pilot holes...)

200 - #9x2.5" screws (I love GRK Mutlipurpose, no pilot holes...)

8 - 1/4"x4" lag bolts

Electrical:

1 - 14 gauge extension cord (3 wire) AT LEAST 25 feet long

3 - one gang electrical boxes

1 - two gang electrical box

1 - toggle switch

3 - outlets

1 - assortment of wire nuts (I ended up using red ones)

1- assortment of colored electrical tape (I used it to identify which cord was what)

10 to 15 - wire staples

3 - outlet plate/covers

1 - switch plate/cover

2 - blank plate covers (just buy two, I messed up the first one; used to mount STC-100)

Temperature control:

1 - 200 watt personal heater (Amazon)

1 - 5k BTU air conditioner

1 - personal desk fan (Amazon)

1 - STC-1000

Insulation:

1 - can of Great Stuff or other expanding foam (16 ounce)

75 sq feet of R15 insulation (I used mineral wool)

1 - bread knife (if using mineral wool)

1 - 3'x25' roll of 4 mil plastic

1 - roll of red sheathing tape

1 - box of 3/8" staples

1 - 1" extruded foam insulation sheet (4X8)

Hardware:

3 - 3/8" hooks (2 for CO2 tank, 1 for clipboard)

2 feet of chain (for CO2 tank)

3 - door hinges

2 - barrel bolts (3")

1 - locking hasp

1 - padlock

1 - utility handle (for door)

Carbon Dioxide:

Fittings for your choice of CO2 set up...none, some or all! Gas hose, fittings, regulator, tank and distributor.

Other stuff:

Stuff to build a ramp OR Buy a Curb Ramp (Only if you have a fermenter on wheels, I bought one)

Zipties

Label maker (to identify the outlets)

8x10 piece of Lexan for temperature conversion chart

Masking tape

Tools:

Staple Gun

Driver/Driver

Bit holder (nice to have a screw guide)

Bits - Phillips, Flathead (GRK screws include bit in the box when purchased at Home Depot)

Drill bit set (1/16 to 1/4)

5/8" hole bit (for electrical)

Dremel tool with rotosaw bit (to cut out the holes in plywood and the blank plate/cover for STC 1000 mounting)

Circular saw

Hammer

Tape Measure

Straight edge

Utility knife

Small Flathead screwdriver (for STC 1000)

Small Phillips screwdriver (electrical work)

Standard size screw driver (hook install)

Pencil

Another pencil

Marker

Another marker

Tape Measure

Irwin Quick Clamps (handy if working alone)

Stud Finder (not required but handy if you forget to mark your studs)

Protective clothing (hat, long sleeve shirt, jeans, boots, gloves, dust mask; mostly for insulation)

Shop vac

Two extension cords for tools

Wire stripper (hehe)

Work light

and of course:

Beer! (Careful around power tools and beer)

I am building this one to be in an unheated (but insulated) garage during North Dakota winters where daytime highs can be -20s ambient.

For most of you it might be overkill. But why kill when you can overkill...

I haven't decided on the final size yet but it will be somewhere in the neighborhood of 4L x 5H x 4W. With a 3x4 door so I can wheel my Brewhemoth in and out.

Constructed of 2x4s and 1/4 inch moisture resistant plywood.

Insulated with R15 mineral wool in the walls and ceiling, floor will be extruded foam panels framed with treated 2x4s.

Run by a STC-1000 with 2 outlets (1 gang) for heat/cool.

It will also have a constant on outlet for a desk fan to circulate air.

A master switch on the exterior will control power to the unit.

All wired from a liberated 14/3 extension cord.

Cooling is a 5,000 BTU window air conditioner.

Heat will be provided by 200 watt personal heater (will it be enough? I am going to find out).

It will also have it's own CO2 supply for force carbing soda and soda water.

I am also thinking about a small shelf for carboys and bottle conditioning.

The top will be strong enough to hold empty buckets and carboys so I am making efficient use of the space in my garage.

I am going to start the floor and framing tonight. Pictures to follow.

I will post a materials list sometime soon. I am planning to knock it out while on paternity leave this week (after SWMBO and kids are in bed).

Materials List

(work in progress, framing (2x4) lumber is an estimate; I may need to add more to this)

Lumber:

10 - 2x4x10'

6 - 2x4x8'

6 - 1/4" plywood sheets (4x8)

1 - 1/2" plywood sheet (4x8)

2 - treated 4x4x8'

3 - 1x4X8' furring strips

6 to 10 - 1x4x8' common board or better for trim

2 - 1x6x8' common board or better for trim

Fasteners:

100 - #10x4" screws (I love GRK Mutlipurpose, no pilot holes...)

200 - #9x2.5" screws (I love GRK Mutlipurpose, no pilot holes...)

8 - 1/4"x4" lag bolts

Electrical:

1 - 14 gauge extension cord (3 wire) AT LEAST 25 feet long

3 - one gang electrical boxes

1 - two gang electrical box

1 - toggle switch

3 - outlets

1 - assortment of wire nuts (I ended up using red ones)

1- assortment of colored electrical tape (I used it to identify which cord was what)

10 to 15 - wire staples

3 - outlet plate/covers

1 - switch plate/cover

2 - blank plate covers (just buy two, I messed up the first one; used to mount STC-100)

Temperature control:

1 - 200 watt personal heater (Amazon)

1 - 5k BTU air conditioner

1 - personal desk fan (Amazon)

1 - STC-1000

Insulation:

1 - can of Great Stuff or other expanding foam (16 ounce)

75 sq feet of R15 insulation (I used mineral wool)

1 - bread knife (if using mineral wool)

1 - 3'x25' roll of 4 mil plastic

1 - roll of red sheathing tape

1 - box of 3/8" staples

1 - 1" extruded foam insulation sheet (4X8)

Hardware:

3 - 3/8" hooks (2 for CO2 tank, 1 for clipboard)

2 feet of chain (for CO2 tank)

3 - door hinges

2 - barrel bolts (3")

1 - locking hasp

1 - padlock

1 - utility handle (for door)

Carbon Dioxide:

Fittings for your choice of CO2 set up...none, some or all! Gas hose, fittings, regulator, tank and distributor.

Other stuff:

Stuff to build a ramp OR Buy a Curb Ramp (Only if you have a fermenter on wheels, I bought one)

Zipties

Label maker (to identify the outlets)

8x10 piece of Lexan for temperature conversion chart

Masking tape

Tools:

Staple Gun

Driver/Driver

Bit holder (nice to have a screw guide)

Bits - Phillips, Flathead (GRK screws include bit in the box when purchased at Home Depot)

Drill bit set (1/16 to 1/4)

5/8" hole bit (for electrical)

Dremel tool with rotosaw bit (to cut out the holes in plywood and the blank plate/cover for STC 1000 mounting)

Circular saw

Hammer

Tape Measure

Straight edge

Utility knife

Small Flathead screwdriver (for STC 1000)

Small Phillips screwdriver (electrical work)

Standard size screw driver (hook install)

Pencil

Another pencil

Marker

Another marker

Tape Measure

Irwin Quick Clamps (handy if working alone)

Stud Finder (not required but handy if you forget to mark your studs)

Protective clothing (hat, long sleeve shirt, jeans, boots, gloves, dust mask; mostly for insulation)

Shop vac

Two extension cords for tools

Wire stripper (hehe)

Work light

and of course:

Beer! (Careful around power tools and beer)