turkeydinner

Member

In Estonia the tempereatures are rarely suitable for fermentation. In summer it is usually to hot and in winter times the heating systems cause it to be too hot. So I decided to build my own fermentation chamber. I read many threads and articles and blog posts about them, and I decided I was going to make an automated system(with temp control). First I tried to find a fridge to suit me, but it seems even old fridges here are very overpriced. Also most of them are too big for my apartment. Even went to check one out, but it was too big to fit into my car, so i disbanded that idea. Instead I decided to build one with peltier elements. I know many people have had unsatisfactory results, but hey, I had to try.

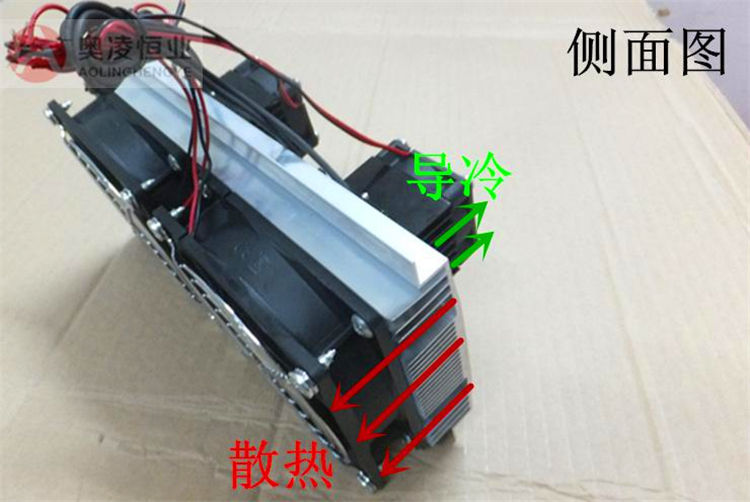

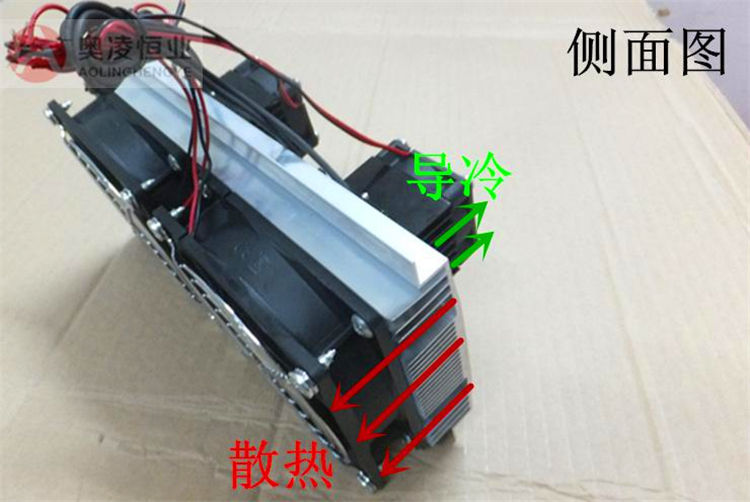

For the peltier, I went with this two-element version:

http://www.aliexpress.com/item/1-se...em-Kit-Cooler-fan-DIY-JSK8299/2032977627.html

And over a couple of weeks constructed the chamber[attached pictures].

Specs:

It has 5cm EPS, 2cm XPS and 6mm plywood. Imperial R value of around 11-12 for walls and bottom, 8 for top(4cm XPS). The R-values are not bad, but the top has two holes in the inner XPS plate for the chiller radiators and fans so it will weaken my insulation factor a bit.

The container outer dimensions are height: 72cm(23.3inches), width and length 60cm(23.6 inches).

Inner height: 56cm(22 inches), width and depth 45cm(17.7 inches).

Experiment:

I finished most of it yesterday. And I put it through a rough insulation test WITHOUT the cooler just to test the insulation. When I get my PSU for the peltiers (hopefully in a few days) I will test that too.

I took it outside where it was about 7C(44.6F) and left it there to cool it down. Then put the lid on and the temperature controller thermometer in and brought it inside where the ambient temperature was 22-23C (71.7-73.4F). I took notes how the temperature changed over time.

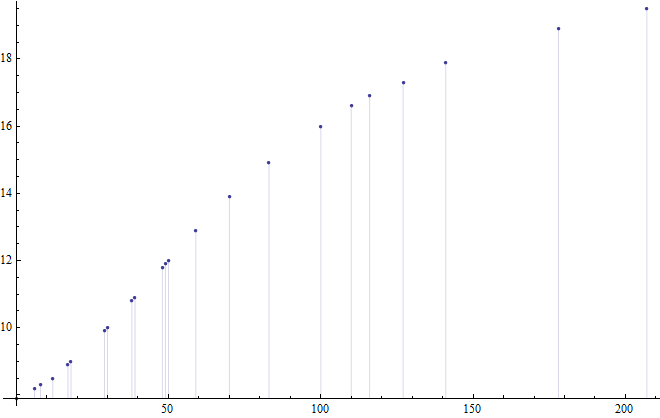

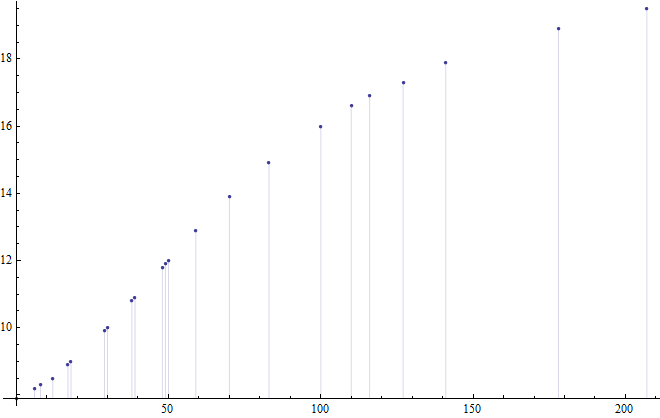

Temperature change in C over minutes, from 7.9C-19.5C during 210 minutes with ambient 22-23C:

Sample points:

0 - 7.9

30 - 10

59 - 12.9

100 - 16.0

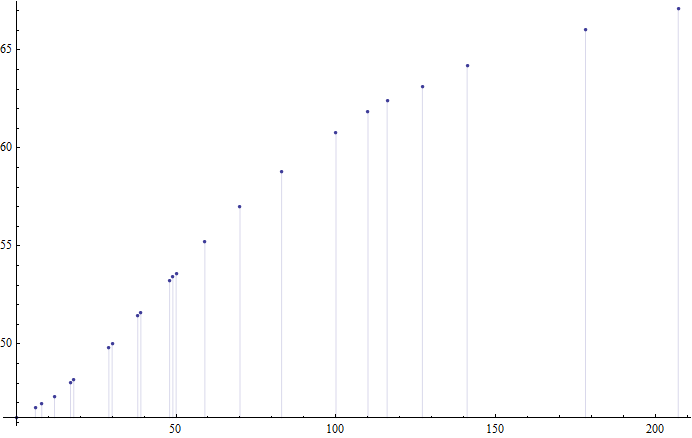

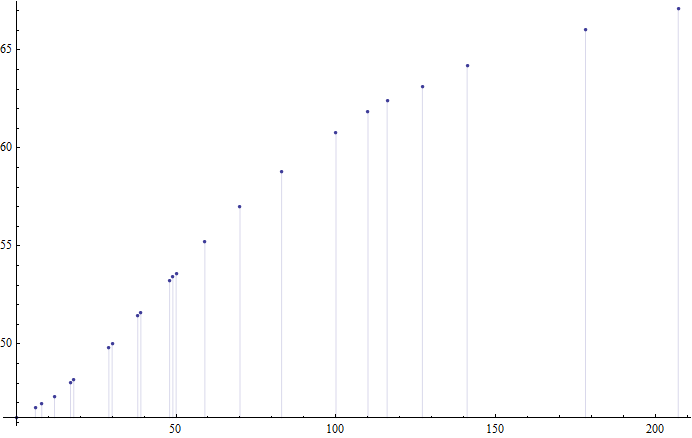

Temperature change in F over minutes, from 46.2-67.1F during 210 minutes with ambient 71.7-73.4F:

Sample points:

0 - 46.2

30 - 50

59 - 55.2

100 - 60.8

But most importantly I also have a question/problem. I have tried to find methods/equations that would help we determine how many watts is thermal conduction moving into my chamber. I would appreciate If someone would help me find this out. Thanks in advance to you.

Further updates are sure to come.

Thank you for reading!

For the peltier, I went with this two-element version:

http://www.aliexpress.com/item/1-se...em-Kit-Cooler-fan-DIY-JSK8299/2032977627.html

And over a couple of weeks constructed the chamber[attached pictures].

Specs:

It has 5cm EPS, 2cm XPS and 6mm plywood. Imperial R value of around 11-12 for walls and bottom, 8 for top(4cm XPS). The R-values are not bad, but the top has two holes in the inner XPS plate for the chiller radiators and fans so it will weaken my insulation factor a bit.

The container outer dimensions are height: 72cm(23.3inches), width and length 60cm(23.6 inches).

Inner height: 56cm(22 inches), width and depth 45cm(17.7 inches).

Experiment:

I finished most of it yesterday. And I put it through a rough insulation test WITHOUT the cooler just to test the insulation. When I get my PSU for the peltiers (hopefully in a few days) I will test that too.

I took it outside where it was about 7C(44.6F) and left it there to cool it down. Then put the lid on and the temperature controller thermometer in and brought it inside where the ambient temperature was 22-23C (71.7-73.4F). I took notes how the temperature changed over time.

Temperature change in C over minutes, from 7.9C-19.5C during 210 minutes with ambient 22-23C:

Sample points:

0 - 7.9

30 - 10

59 - 12.9

100 - 16.0

Temperature change in F over minutes, from 46.2-67.1F during 210 minutes with ambient 71.7-73.4F:

Sample points:

0 - 46.2

30 - 50

59 - 55.2

100 - 60.8

But most importantly I also have a question/problem. I have tried to find methods/equations that would help we determine how many watts is thermal conduction moving into my chamber. I would appreciate If someone would help me find this out. Thanks in advance to you.

Further updates are sure to come.

Thank you for reading!

Attachments

Last edited: