Well when my brewing partner and I meet we quickly clicked and we started making killer beers. We both improved quickly and we decided to pull our resources together and build a nice 3 vessel single tier system. As the quality of our beers increased we decided it was time to rebuild and add some new toys.

We started the rebuild and here is what's planned:

Original Setup

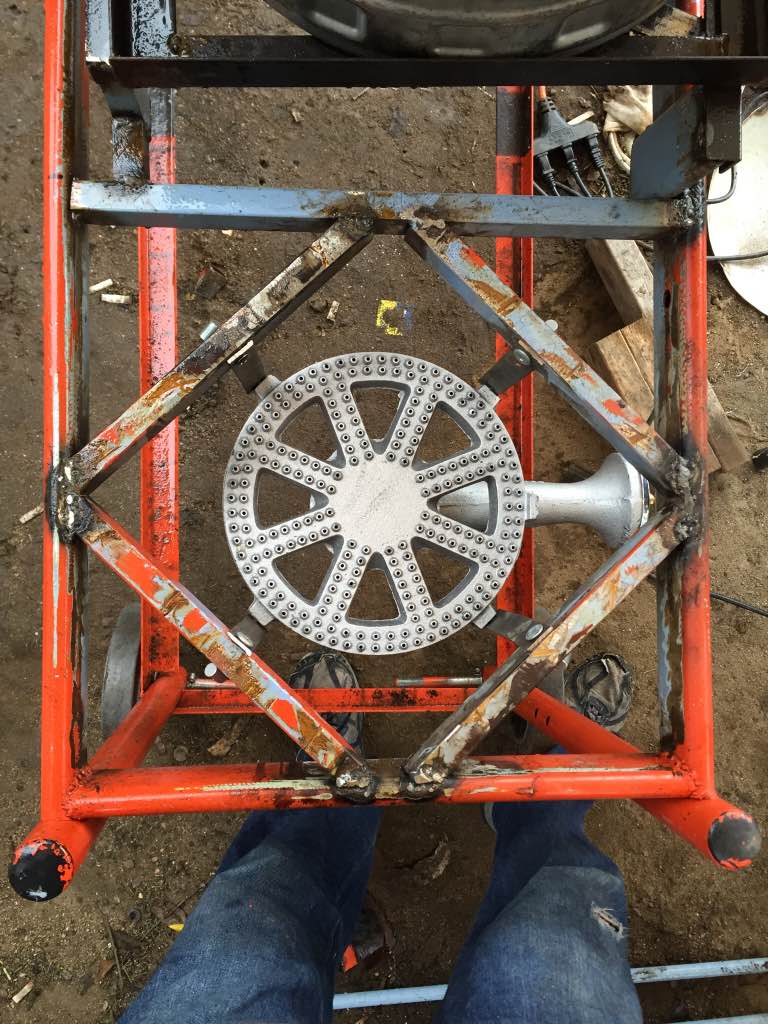

Single tier, 2 pumps with plastic quick disconnects. It works but we want more!

We started the rebuild and here is what's planned:

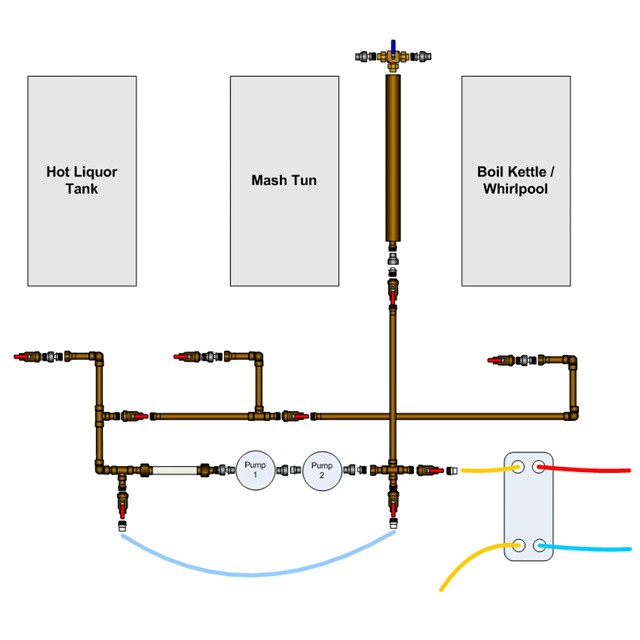

- New burners and propane manifold system as well move to natural gas. We will be using BG-14 burners which are rated at 210,000 BTUs.

- Camlocks, we used plastic quick disconnects but time for more something easier that would not restrict the flow.

- Hard Plumbed with 1/2 copper and all valve controlled. No more jumper hoses!

- RIMs temp control, a 1500w 120v inline electric element will monitor and maintain the mash temp. Initially controlled by a pid but will be arduino controlled.

- custom hop back to pack in that aroma

- prechiller in a 5g igloo with 25ft of copper tube will help with our stubborn ground temp

- inline sight glass so we can monitor the wort color

- hot liquor tank sight glass to better calculate how much water we have and added.

- 2 inline pumps so there is never a problem with flow or priming.

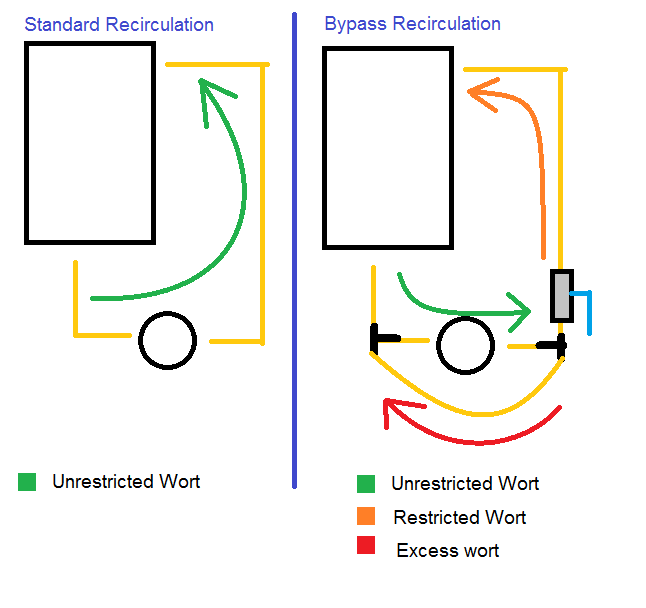

- recirculation bypass so we never put excess pressure on the grain bed and maintain our desired flow

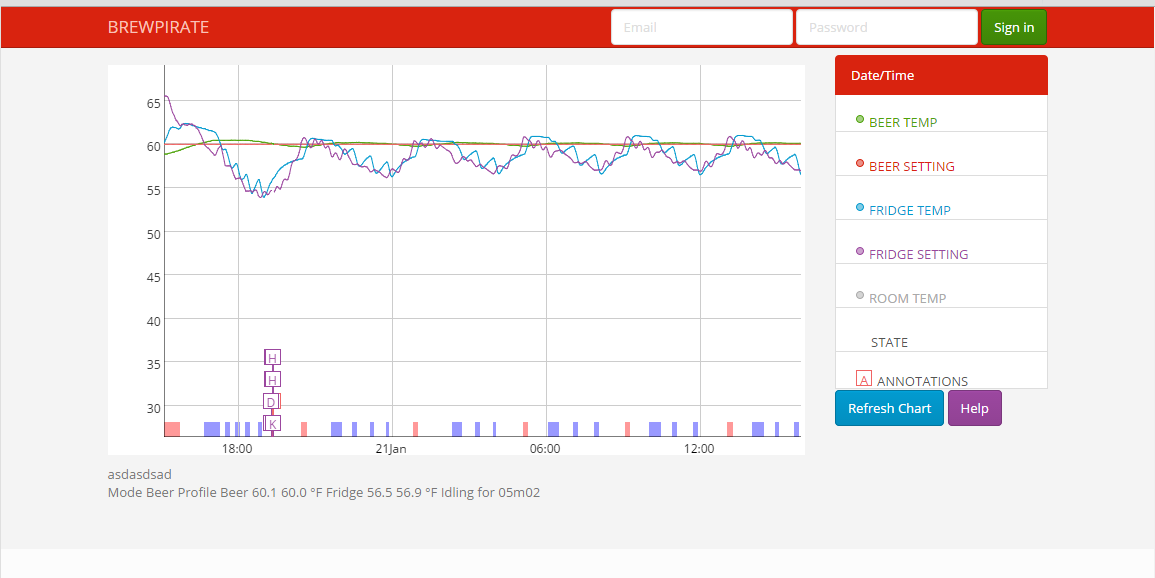

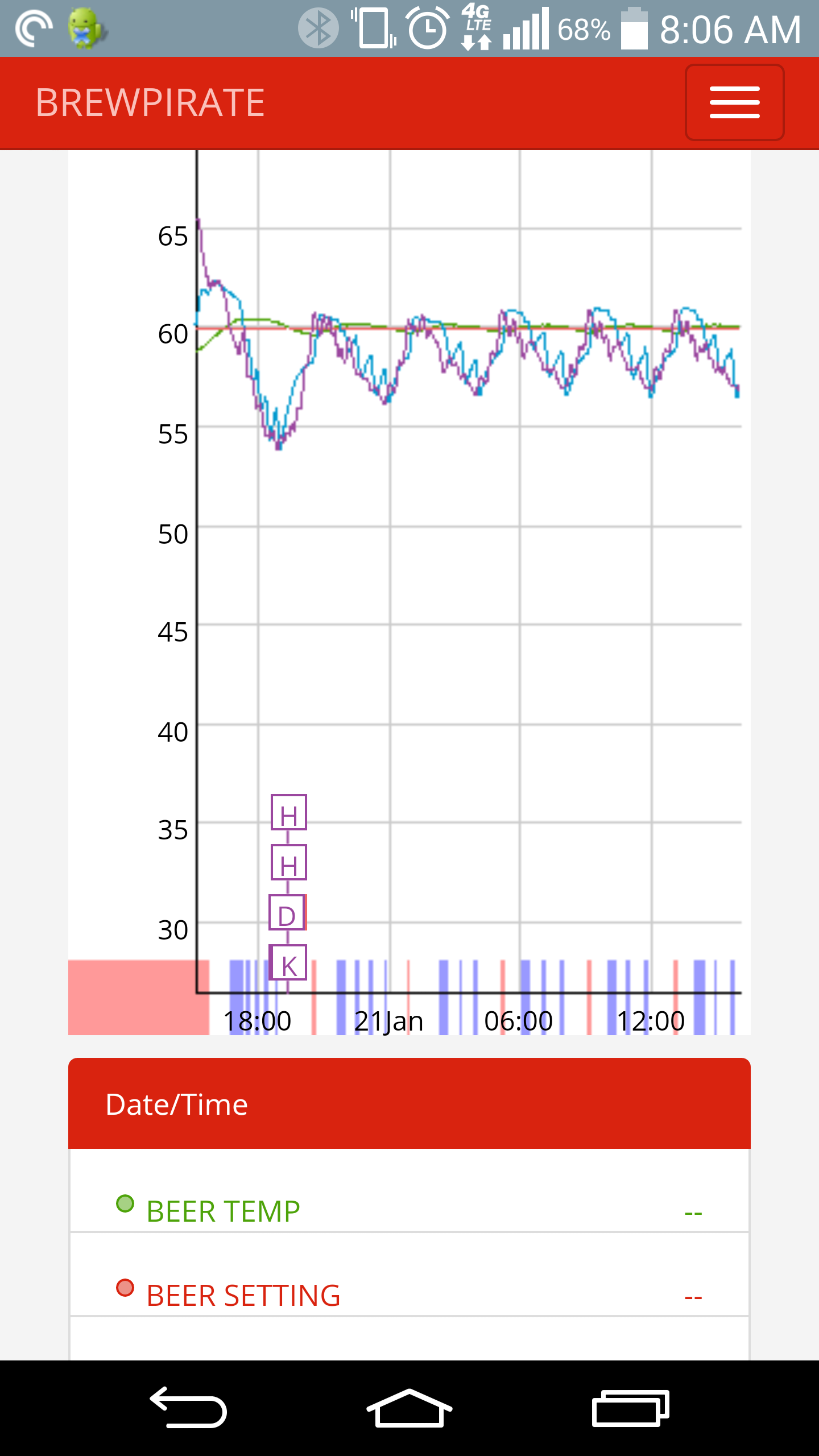

- Strangebrew Elsinore Brewery Controller on Raspberry PI

- Redesign of Brewpi and integration with URL="https://www.homebrewtalk.com/f170/new-strangebrew-elsinore-thread-475456/"]Strangebrew Elsinore [/URL]

Original Setup

Single tier, 2 pumps with plastic quick disconnects. It works but we want more!