Wow, nice save on the CMOS. Glad to hear it's worked out. Now, before you do anything else...BACK UP YOUR DATA!!! I'm sorry, but I lost a 17 page research paper once to a corrupted sector. Since then I back up the system, and backup all my school and work related stuff online through school. I just can't have that happen again.

With the recipe, I'm using great western for the base malt, so your pale malt will be just fine. For the rye I'd sub 2lbs of rolled and up the base malt by a pound to compensate. As far as the crystal rye, just go with half a pound of some crystal/carmel 100ish barley. That will get you most of the way there, and if you decide that you like the dry, spicy rye flavor just up the amount next time. As far as hops, I chose glacier because they're my current favorite, and the spicyness plays really well with the rye, but I imagine it'd be great with any spicy/earthy hop variety that you have handy. Let me know what you do and how you like it. I'm always interested in improving my recipes.

Back on topic, I rebuilt the RIMS and it's leak free. I also fixed the one pinhole leak in the MT/LT. Just doused it in flux and heated it back up until the solder flowed again. I ran a batch of oxyclean through it. The MT/LT started at 52, and it got up to 175 in about 35 mins with the pump going full guns. I moved that over to the BK and had a nice rolling boil at 100% in about 15 mins. I'm now running a batch of water through it, and will do the same again tomorrow. I'm continuing to iron out the kinks before I actually put grain into it.

When I rebuilt the RIMS I flipped ends, and oriented the input horizontally to facilitate draining and keep air out of the tube. It's much easier to use in this configuration, and with the ball valve on the input I'm able to keep it flooded to prevent dry firing the element. I had some issues this time getting the element far enough into the 2"x1" reducer bushing to get a good seal with the gasket. I'm considering tapping the thread to NPS on that bushing so I can tighten it down all the way and really sandwich the box. Has anyone done this? How hard is it to get a 1" tap into a stainless bushing that's currently cut for NPT? Where would I go to have it done? I'd hate to spend $$$ on a 1" tap that I'm only going to use once only to find out that I can't turn it in by hand.

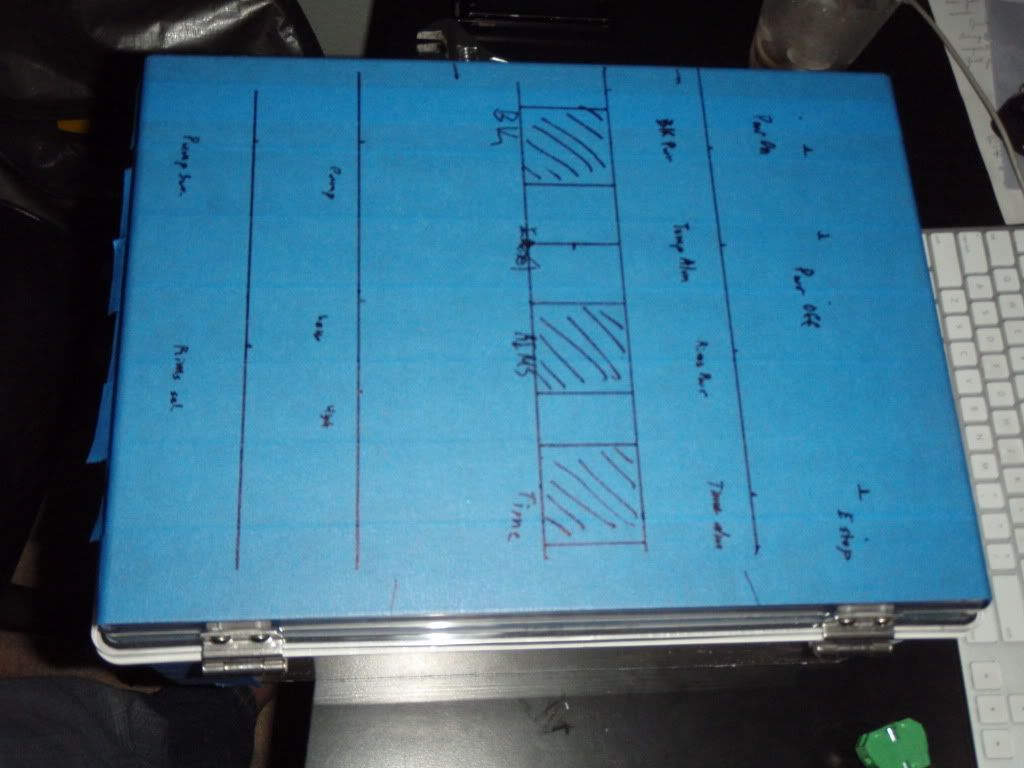

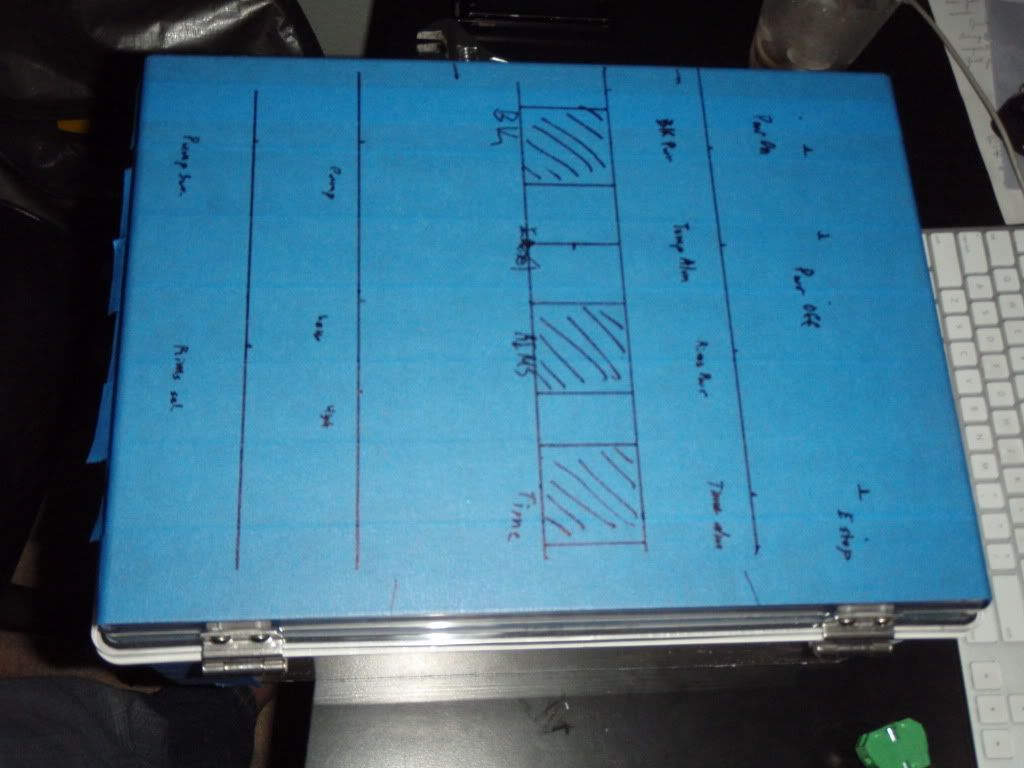

Here's the new RIMS setup:

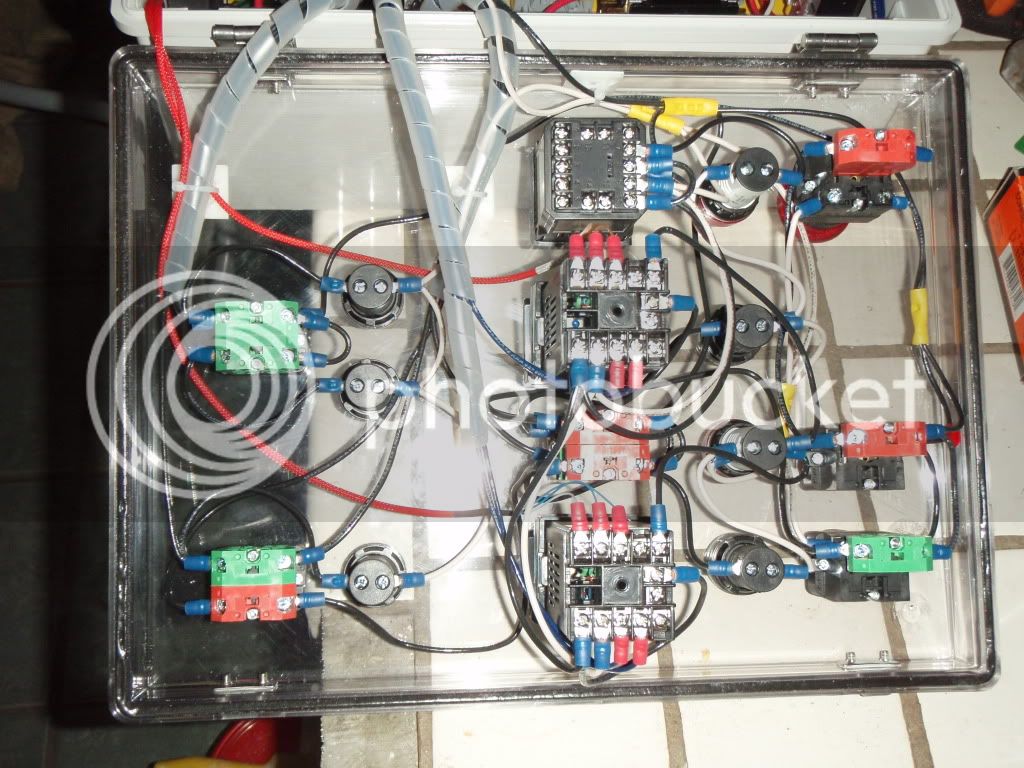

And here's the rig doing a water run, the CP's inside, the rest is on the patio:

Here's 14ish gallons of water at full boil on 65% pwr:

One last question for tonight, what settings does everyone use for their BK that's controlled by an Auber PID? I have it on manual at 100% to get to a boil, then 60% to maintain, but it cycles between a crazy boil when the 5500w is on and nothing when it's off. Right now the cycle time is 2s, which seems to be the minimum. Is this what everyone else runs? Since it's uninsulated and ambient was around 50 today I'm probably using a lot more power than I need to, but I want to get a couple beers in the fermenter before I actually polish and insulate the kegs, just in case I decide to make changes after a bit of getting used to one another.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)