TheFlyingBeer

Well-Known Member

Tho I hadn't considered LabView - mostly because I don't have access to it!

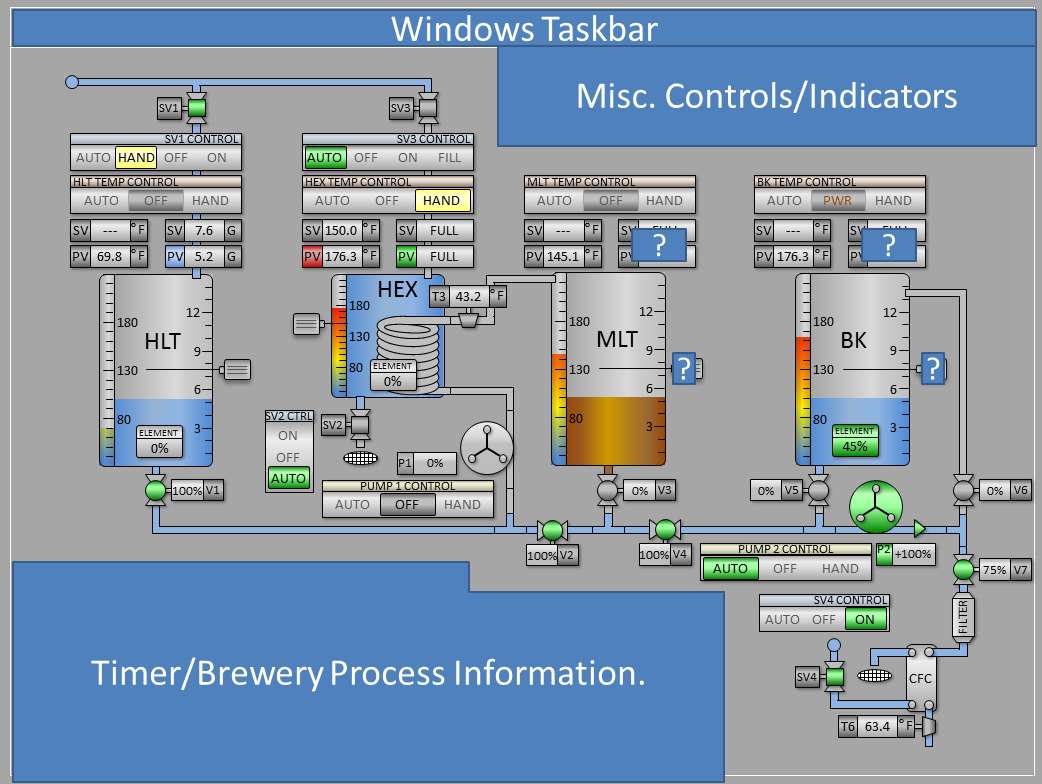

Luckily I can build executables that run without a full LV installation on the brewery PC.

... how do drain the sink ? Is that a sump pump ?

I actually changed a lot of the plumbing around in my basement because: 1. needed to run a drain and a couple water lines to the brewing room, 2. old plumbing was not that great. Tomorrow I will be finishing up the plumbing to the sink. I was lucky the storage room I am turning into the brewing room was near both my laundry room and my main electrical panel.

That is actually a picture of my old sump pump which was in drastic need of replacement. Yesterday I installed a new fully submerged pump and cover.

I don't plan on using the sump as a drain unless I am washing the floor or have any major spills.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)