Ha ha. Bummed out. I just typed it all up and then messed up and erased it all, so I will try again.

Sorry for the delay, but I work long days right now so finding time to do stuff like this is sparse.

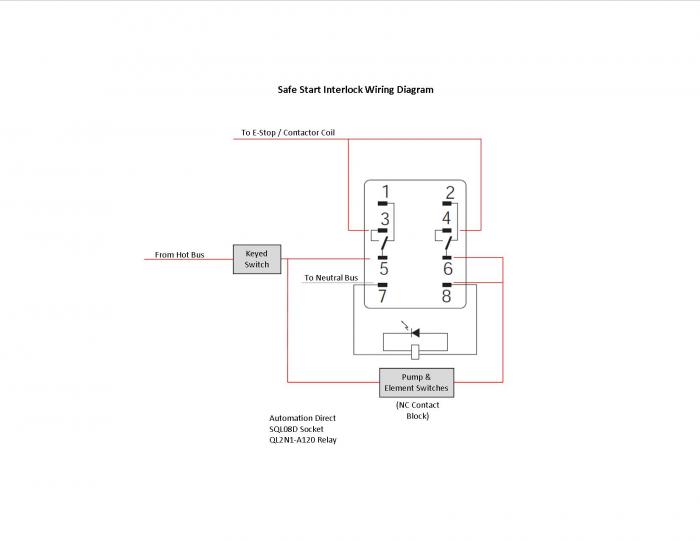

Tracing out the circuit you are taking a control leg from one of the 120v phases and bringing it to the keyed switch, then from the keyed switch to point 5 on the interlock. This is your main control point, if the key is on but the mushroom button is pushed in, the lights will light up saying its on, but nothing will work.

The wire that taps off the other side of the keyed switch starts your control circuit, runs through all your devices, and ends up back on the interlock points 8 and 6. So point eight just brings power to the interlocks relay telling it to turn everything on, and the grey wire from points 7 to 8 with the diode in parallel with it should be factory wired.

Point 7 on the interlock is simply your return, so it is one wire going to your neutral bus.

From point 5 to 1 is a NC contact and so is 6 to 2.

From point 5 to 3 is a NO contact, and so is 6 to 4. Points 3 and 4 are both what you bring back to your E-Stop, and ultimately your A2 point on the AUX Relay on the main Contactor. That is the full control circuit where the interlock is involved.

Essentially you are creating a logic circuit saying "If the key is on, but the E-stop is off, turn your lights on but with no operability. If the key is on and the E-stop is on, then everything is on with operability. If the key is off at all, or both are off then nothing is on at all."

After tracing it all out I'm a little confounded though. I don't think you actually needed the interlock at all. You might as well use it, but you could have wired it all the same where the keyed switch goes through the control circuit and to the E-stop. That would have provided the same results since the NC circuits are not used at all.

Good luck dude. Once again sorry for the late reply, but hopefully good brewing is afoot with your setup.