slym2none

"Lazy extract brewer."

Yes, after 3 months of saying I am going to go AG, and 2-1/2 months of always seeming to have extract I don't want to waste or give up, I am finally plunging into my very first, true all-grain batch tonight. Made with whole-cone hops for the most part, I am making a 3-gallon batch in hopes I get 2.5 out of it. 3.5G boil in a 4-G pot ought to be fun!

Here's my recipe:

My Experimental IPA Ver. 1.0

---------------------------------------

Style: IPA

Brewer: slym2none

BIAB, 75% brewhouse efficiency

calc. OG - 1.071, act. - 1.074

calc. FG - 1.015, act. -

calc. ABV - 7.3%

55 IBUs, assuming 6%AA for the experimental hops (68 if 12%)

4.5 SRM

3.5 gallon boil

3.0 gallons - .5 gal for hops absorption, 2.5 gallons in fermentor

6.0 pounds 2-row

0.5 pound Munich II (20L)

0.5 pound wheat

mashed at 153 for 75 minutes in 2.5 gallons water - sparge with just enough water to get to 3.5 gallons for the boil

60 minute boil

0.5 pounds sugar (late addition)

0.5 oz Nugget 45 minutes (15%AA)

0.5 oz "experimental hops" @ 22 minutes

0.5 oz "experimental hops" @ 7 minutes

2.0 oz "experimental hops" in hop-stand: 55 minutes starting at 170F

0.5 oz Cascade whole-cones in hop-stand

1.0 oz Citra hops for dry-hop 1 (for 3-4 days, after primary fermentation)

1.0 oz Simcoe hops, dry-hop 1

Nottingham Yeast, fermented at 62F

Yes, a 75-minute mash, to ensure I get complete conversion, as my LHBS' grind is good, but not great, for BIAB. I am also mashing at 150 because Notty always over-attenuates, so this should help keep my FG close to where it ought to be, instead of the 5-7 points lower that Notty always gives me. A little sugar late to help dry it out. The experimental hops are the whole cones @aprichman was giving away, and I have no idea where they are exactly in AA% nor flavour, although he gave me an idea of the flavours. Hopefully, Citra & Simcoe will compliment them nicely for a dry-hop. (No, no whole-cone hops in the dry-hopping!)

Tap water, 4.5G, treated first with Campden, then 1 tsp. gypsum to get this more in-line with an IPA water-formula. Hope this works out.

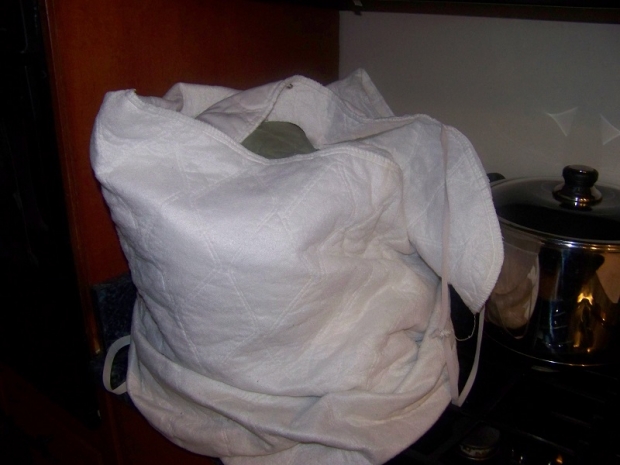

Pics & a story to come when I get started later.

Here's my recipe:

My Experimental IPA Ver. 1.0

---------------------------------------

Style: IPA

Brewer: slym2none

BIAB, 75% brewhouse efficiency

calc. OG - 1.071, act. - 1.074

calc. FG - 1.015, act. -

calc. ABV - 7.3%

55 IBUs, assuming 6%AA for the experimental hops (68 if 12%)

4.5 SRM

3.5 gallon boil

3.0 gallons - .5 gal for hops absorption, 2.5 gallons in fermentor

6.0 pounds 2-row

0.5 pound Munich II (20L)

0.5 pound wheat

mashed at 153 for 75 minutes in 2.5 gallons water - sparge with just enough water to get to 3.5 gallons for the boil

60 minute boil

0.5 pounds sugar (late addition)

0.5 oz Nugget 45 minutes (15%AA)

0.5 oz "experimental hops" @ 22 minutes

0.5 oz "experimental hops" @ 7 minutes

2.0 oz "experimental hops" in hop-stand: 55 minutes starting at 170F

0.5 oz Cascade whole-cones in hop-stand

1.0 oz Citra hops for dry-hop 1 (for 3-4 days, after primary fermentation)

1.0 oz Simcoe hops, dry-hop 1

Nottingham Yeast, fermented at 62F

Yes, a 75-minute mash, to ensure I get complete conversion, as my LHBS' grind is good, but not great, for BIAB. I am also mashing at 150 because Notty always over-attenuates, so this should help keep my FG close to where it ought to be, instead of the 5-7 points lower that Notty always gives me. A little sugar late to help dry it out. The experimental hops are the whole cones @aprichman was giving away, and I have no idea where they are exactly in AA% nor flavour, although he gave me an idea of the flavours. Hopefully, Citra & Simcoe will compliment them nicely for a dry-hop. (No, no whole-cone hops in the dry-hopping!)

Tap water, 4.5G, treated first with Campden, then 1 tsp. gypsum to get this more in-line with an IPA water-formula. Hope this works out.

Pics & a story to come when I get started later.