SlitheryDee

General Manager

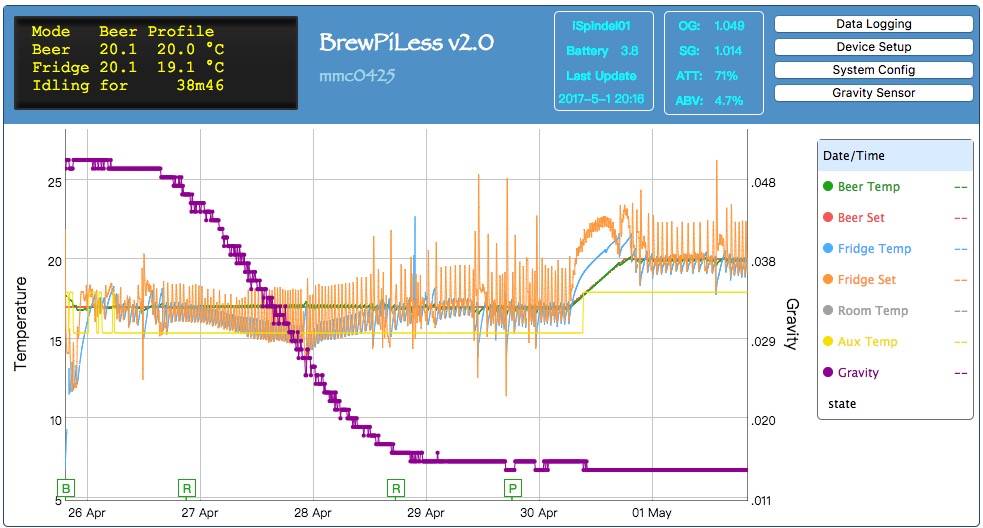

So I put an irish amber ale in the fermenter Saturday. It's the northern brewer kit with steeping grains, and I added a bit of DME to it to give it a bit more kick. The OG as measured was 1.052 and my expected FG according to brewer's friend is 1.012. I just check the gravity last night and was shocked to see it at 1.012 already. There were also signs of a massive krausen that had already fallen back into the beer. That's just three days of fermentation time for nottingham??

My procedure:

This is my first beer to ferment with temperature control, so I cooled it in the fermentation chamber to 66 degrees before pitching, and fermented at that same temperature from Saturday through this morning. This morning I bumped the temperature up to 75 degrees as per the brulosophy ale schedule I'm following. This puts me at beginning to cold crash sometime this weekend, and that's probably giving it a couple days more than it needs. Pretty incredible. If I kegged I could conceivably be drinking this beer next week.

My procedure:

This is my first beer to ferment with temperature control, so I cooled it in the fermentation chamber to 66 degrees before pitching, and fermented at that same temperature from Saturday through this morning. This morning I bumped the temperature up to 75 degrees as per the brulosophy ale schedule I'm following. This puts me at beginning to cold crash sometime this weekend, and that's probably giving it a couple days more than it needs. Pretty incredible. If I kegged I could conceivably be drinking this beer next week.