Hello,

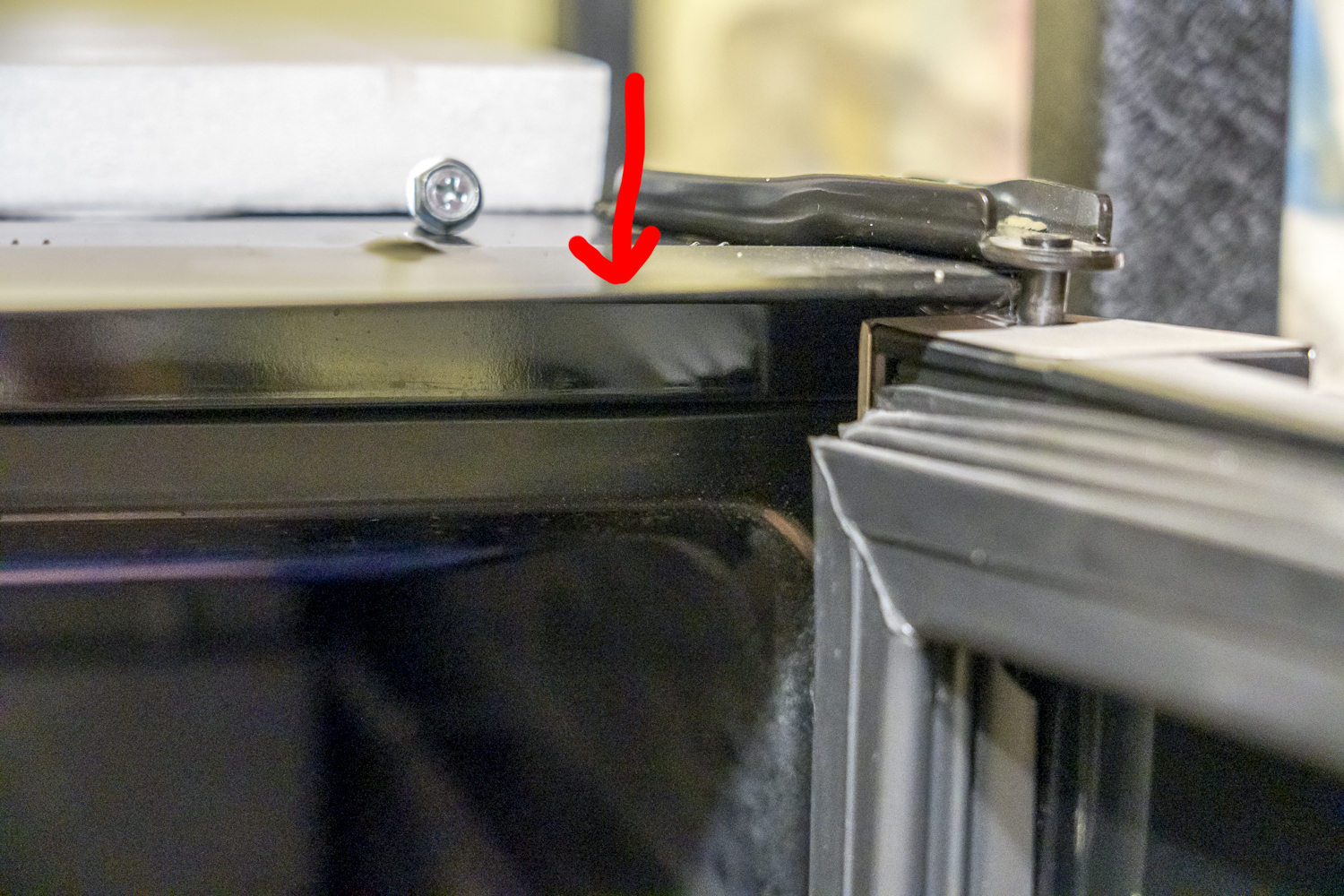

I have a GE pwr04fanbs wine Fridge that I would like to run EVA barrier tubing out for CO2 capture from fermentation to purge my keg and spund. But I am verklempt about how to get the tubing out - drill or squeeze it through the door seal? I do not want to kill the fridge. I know it has coils in the sides but not much more than that. Called GE and they would not have any part in telling me anything.

So I thought I would ask if anybody has worked with this unit. I have read all of the threads and know it is a guess and leap of faith in the end!

Thanks for your input.

I have a GE pwr04fanbs wine Fridge that I would like to run EVA barrier tubing out for CO2 capture from fermentation to purge my keg and spund. But I am verklempt about how to get the tubing out - drill or squeeze it through the door seal? I do not want to kill the fridge. I know it has coils in the sides but not much more than that. Called GE and they would not have any part in telling me anything.

So I thought I would ask if anybody has worked with this unit. I have read all of the threads and know it is a guess and leap of faith in the end!

Thanks for your input.