blackheart

Well-Known Member

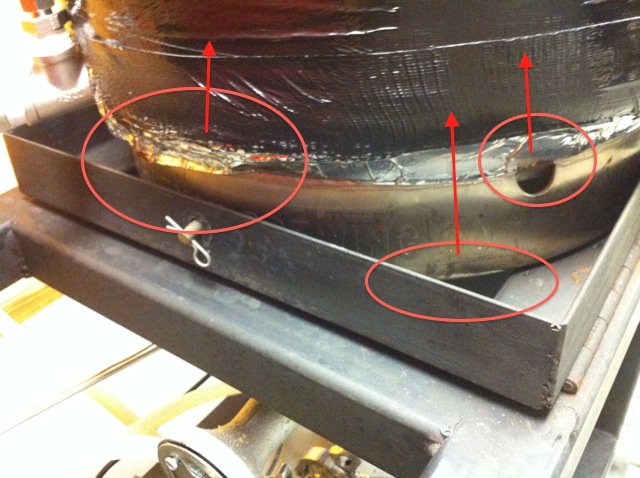

We were all set to brew a batch on our new all grain system when we noticed the outside of our insulation starting to melt and come unglued. The problem was heat from the two burners was creeping up the sides of the insulation and we could not fix it on the spot so we had to cancel the brew day.

Here is a picture showing where the problem areas are.

We used a 1/2" sheet of wool wrapped in 2 layers of duct tape. A foil waterproof tape was used at the top and bottom to hopefully deflect some heat and add a waterproof seal. None of this worked as expected after about 20 min of the burners being turned on.

The problem is that if we want to hit any of our target brew dates to have beer for the holidays/new years we need to get brewing asap, ideally, next weekend.

What we need to do is find a solution to shield the insulation from heat, maybe some kind of skirt, or deflector or wrap or something else, but we are hoping to figure that out soon, order what we need and patch this problem up before the weekend.

If you have some experience with this or have a suggestion we would love to hear them.

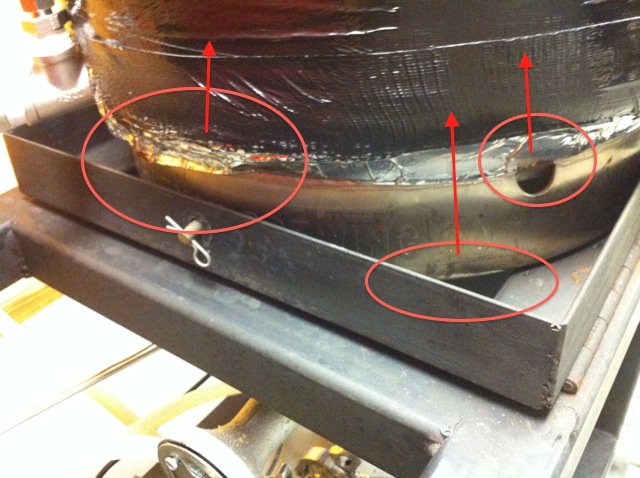

Here is a picture showing where the problem areas are.

We used a 1/2" sheet of wool wrapped in 2 layers of duct tape. A foil waterproof tape was used at the top and bottom to hopefully deflect some heat and add a waterproof seal. None of this worked as expected after about 20 min of the burners being turned on.

The problem is that if we want to hit any of our target brew dates to have beer for the holidays/new years we need to get brewing asap, ideally, next weekend.

What we need to do is find a solution to shield the insulation from heat, maybe some kind of skirt, or deflector or wrap or something else, but we are hoping to figure that out soon, order what we need and patch this problem up before the weekend.

If you have some experience with this or have a suggestion we would love to hear them.