Cider Wraith

Well-Known Member

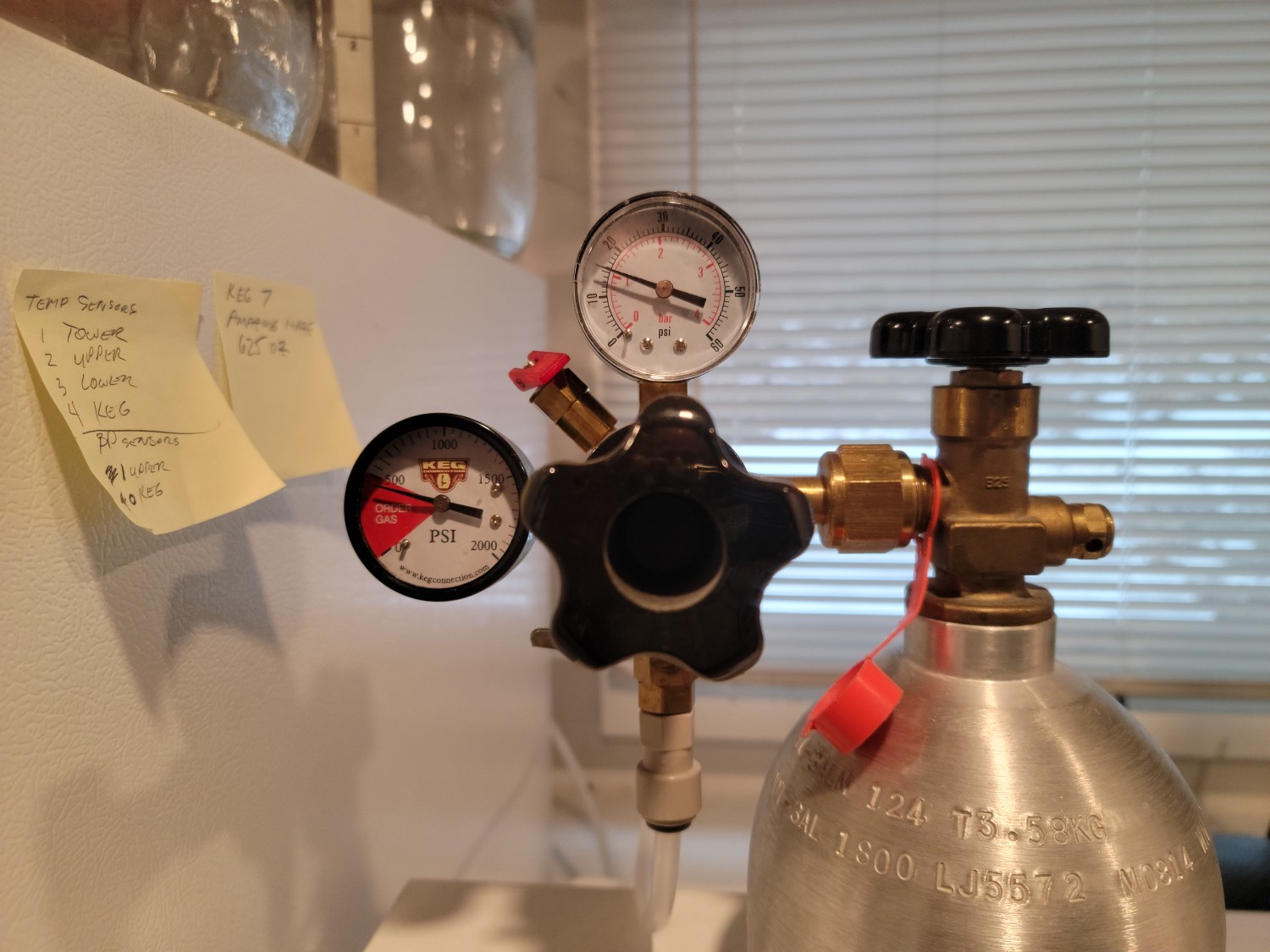

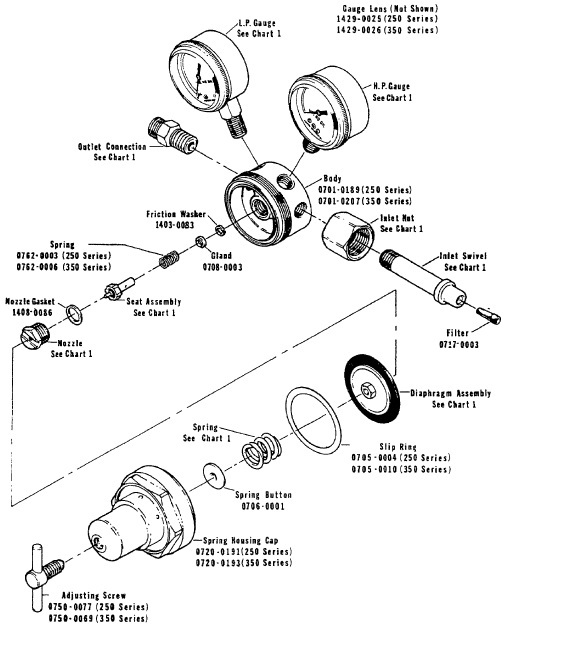

Could anyone please give a recommendation on how to upgrade a regulator flat blade screw to a rubber handle? Purchased a couple of regulators with this "tamper proof" option but a rubber handle would be better. Tried unscrewing the screw and it seizes, won't fully back out. Could possibly tape something like a framing nail into the screw slot but that sounds like a last resort. Could some type of rubber handle be slipped over the screw head giving a quick retrofit? Suggestions appreciated, thanks -