Are there any other things that I am missing that could help with my issue(s)?

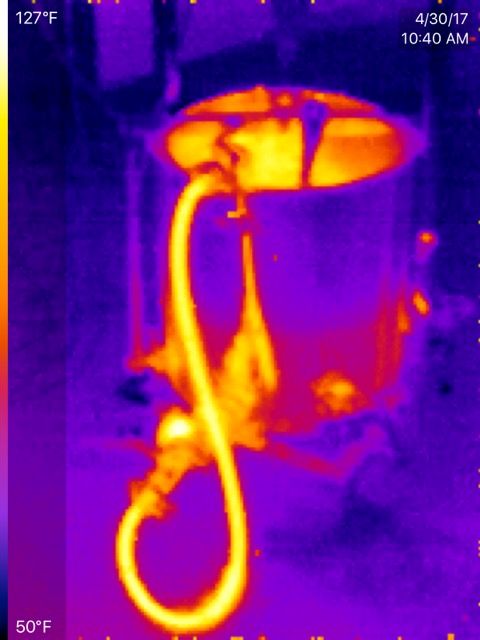

Feel free to stir your mash. I've thought a lot about re-circulation and what the benefits are. I think (and feel free to disagree) that one of the primary benefits of re-circulation is keeping a constant mash temp. Consider this. If your grain is at mash temp, and you're surrounding that grain bed with an envelope of constant temp wort, there is no place for heat to escape. Thats a good thing. Any mechanical "sweeping" of sugars from the grains that you get from re-circulation is a bonus - buts lets face it. Re-circulating wort is going to take the path of least resistance, whether its through the side walls of an all mesh basket or through channels in the grain bed itself. If the grain bed were fluidized, re-circulation would work marvelously, but its not. Stick a spoon in your mash and you can feel that it's dense at the bottom. I don't think that any of us should rely solely re-circulation to mechanically liberate sugars from the grain. I really think that regular stirring of the mash does the trick.

For big grain bills, I would absolutely hold back some water for a sparge. Mashing thicker and sparging should help you gain some gravity points.

The SS Brewtech manifold looks like a slick tool. I think its benefit is that it probably creates more channels in the grain bed, and that's not all bad. I'm sure that it helps with the flow through a solid side basket.

Finally, mill gap is going to be directly related to your basket type. I just checked mine with a feeler gauge and I'm set at .025". From what I've been seeing on this thread, I would not recommend that for a solid side basket.

Final shout out to jabba11. My daughter graduated from KSU. What a neat town you live in. Sorry to hear about Grandpa Bill.

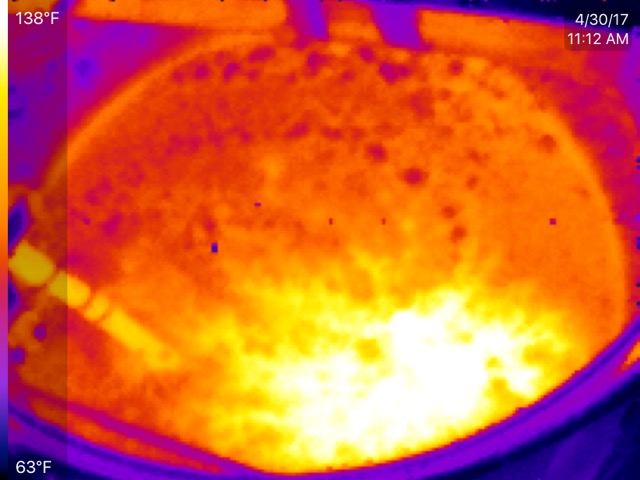

AWESOME and very EMAW!. Bill Snyder kicks cancers ass then sends it a nice letter. Anyhow I have taken to doing a one gallon rinse at the end of my mash. Seems to help a little bit