This summer, the now wife decided to impulse buy homebrew equipment to give me a new hobby. Fast forward 6 extract batches, and I was ready to do all grain, but I soon found out the stand the guy sold her left quite a bit to be desired. I realized after another 6 batches that it was large, cumbersome, couldn't store inside, casters too small for rolling around outside, burner was a bit weak, and there were burrs on almost every edge of tubing. I decided to put my skills to use and design and build a stand that fit my needs.

I currently use an el cheapo aluminum stock pot to heat strike water, have a 52 qt Coleman Extreme cooler mash tun, and a keggle for the boil.

Main design criteria:

1. Small footprint- Stand takes up a 19x20 inch area when folded

2. Gravity feed- Mash --> Boil --> Brew Bucket or carboy

3. 10 inch Banjo burner

4. Hold 30 lb Propane tank

5. Allow for tilting of the mash tun to get the wort towards the sump

6. Sit on casters, but be light enough to pick up and into my truck without help

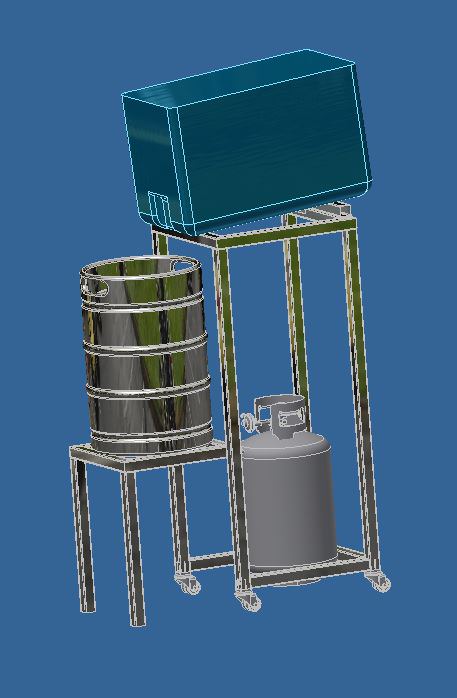

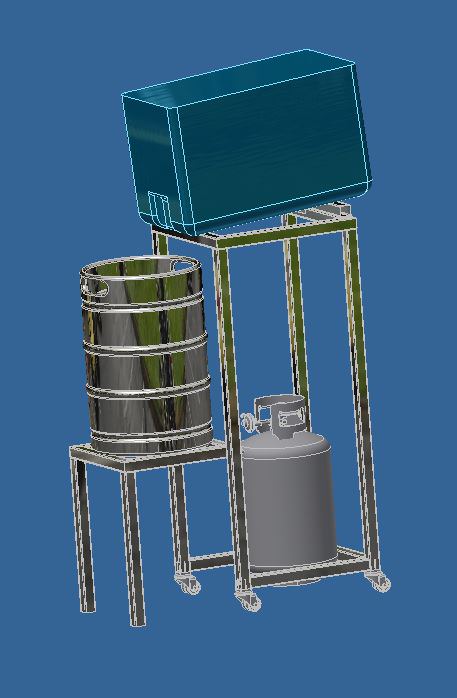

Step one was to sit down and make a solid model of all the parts and get elevations set.

I settled on 1.5" 16 gauge square tubing. Light, plenty strong, and fast to cut and weld.

Under the mash tun is a short length of tubing on hinges to lift the rear of the cooler, satisfying criteria #5. Mash tun surface is 48.5 inches off the ground, burner surface is 21.5 inches off the ground.

I then ordered two sticks of tubing, and got to cutting and welding.

I bought a Bayou Classic KAB4 burner, and cut the legs off and welded that in my square tubing frame. I didn't take any close ups of this however. Weld hinges were used to mount the burner tier to the main stand. To mount the stem casters, I bought threaded tube inserts from Mcmaster. I could have machined a plate, or welded a nut somewhere, but the convenience is worth it IMO.

I then fabbed up a tray to hold my tank 1/2" off the ground.

Here is the stand in brew mode

and here is the stand in storage mode

Finally, in the garage

and breaking it in!

Total cost:

Steel $38

McMaster order (inserts, casters, hinges) $65

KAB4 Burner $75

90 degree 3/8 swivel flare fitting $9

Total $187

I haven't put it on a scale, but picking it up and putting it in my truck is a piece of cake.

I currently use an el cheapo aluminum stock pot to heat strike water, have a 52 qt Coleman Extreme cooler mash tun, and a keggle for the boil.

Main design criteria:

1. Small footprint- Stand takes up a 19x20 inch area when folded

2. Gravity feed- Mash --> Boil --> Brew Bucket or carboy

3. 10 inch Banjo burner

4. Hold 30 lb Propane tank

5. Allow for tilting of the mash tun to get the wort towards the sump

6. Sit on casters, but be light enough to pick up and into my truck without help

Step one was to sit down and make a solid model of all the parts and get elevations set.

I settled on 1.5" 16 gauge square tubing. Light, plenty strong, and fast to cut and weld.

Under the mash tun is a short length of tubing on hinges to lift the rear of the cooler, satisfying criteria #5. Mash tun surface is 48.5 inches off the ground, burner surface is 21.5 inches off the ground.

I then ordered two sticks of tubing, and got to cutting and welding.

I bought a Bayou Classic KAB4 burner, and cut the legs off and welded that in my square tubing frame. I didn't take any close ups of this however. Weld hinges were used to mount the burner tier to the main stand. To mount the stem casters, I bought threaded tube inserts from Mcmaster. I could have machined a plate, or welded a nut somewhere, but the convenience is worth it IMO.

I then fabbed up a tray to hold my tank 1/2" off the ground.

Here is the stand in brew mode

and here is the stand in storage mode

Finally, in the garage

and breaking it in!

Total cost:

Steel $38

McMaster order (inserts, casters, hinges) $65

KAB4 Burner $75

90 degree 3/8 swivel flare fitting $9

Total $187

I haven't put it on a scale, but picking it up and putting it in my truck is a piece of cake.

Last edited: