So, I'm working on my new brew rig build and messing with the BG14 burners. I know they don't put out the same heat as the wok/jet burners, but I needed to do some testing to find out what the real output is. My testing was really focusing around changing burner heights to allow better combustion and spent gas escaping to try and find the sweet spot for best efficiency. High pressure propane doesn't have the low velocity problems that NG does and even low pressure propane works much better with these burners. My boils are usually around the 20 gallon mark, so I need to make sure I can adequately get 20 gallons up to boiling in a reasonable amount of time.

For my tests, I heated 10 gallons of water for 30 minutes and measured the temperature at 10 minute increments. No matter what burner is used, temperature gains slow the hotter it gets, but I feel a 30 minute test gets things hot enough to judge the effective heating ability.

As a comparison, I did baseline heat tests with my 6", 10 tip wok/jet burners on my old brew stand. Starting at 80 degrees, my wok/jet burners heated, 31, 31 & 28 degrees in the three 10 minute durations. This gave me an even 90 degree rise in 30 minutes.

When I started testing the BG14 burners at different heights, I was only getting 21 degrees rise every 10 minutes for a total of 63 degrees over the whole 30 minutes. When I was looking at the flames on the BG14 burner, there was definite yellowing going on which tells me that it is running rich and there isn't full combustion happening.

I've done tests a few years back with a BG14 and knew it wouldn't be up to the level of the wok burners, but I was pretty surprised at the test results I had just experienced. Other tests I've done didn't have the wind screens, so I know it wasn't really a lack of venting. Knowing that the wok burners perform so much better (50% better) using the same gas hookup tells me that the wok burners are able to burn much more of the available fuel. That means it all comes down to the AFR (air fuel ratio) and being able to get a leaner/hotter burn. So that got me thinking about how to add additional air to the mix to get a full burn out of the available gas. The answer - supercharge it!

As a proof of concept test, I used the air gun from my air compressor and dialed the output pressure down to about 8-10 PSI. When blowing from the air gun, it was just a good light constant flow, but not heavy duty like when you use the air gun to blow or clean things up (which usually is around 80+ PSI). I zip tied the air gun lever to stay on and pushed it into the venturi opening of the BG14 bell housing. HOLY **** is all I can say! Every tip on the BG14 was burning solid blue at about 1" in height. This baby was putting out serious BTU's now!

So, time to re-do the 10 gallon heat test. The first 10 minute segment gave me a 42 degree rise!!! The second 10 minutes was 38 degrees and the 3rd one was 30 degrees (remember, the hotter it gets, the lower the rise per minute). That was 110 degrees in 30 minutes - compared to the 63 degree rise without air assist. Gas flow was the same between the tests, only the addition of forced air was different. That's a 75% increase in BTU output by just feeding air into the venturi!

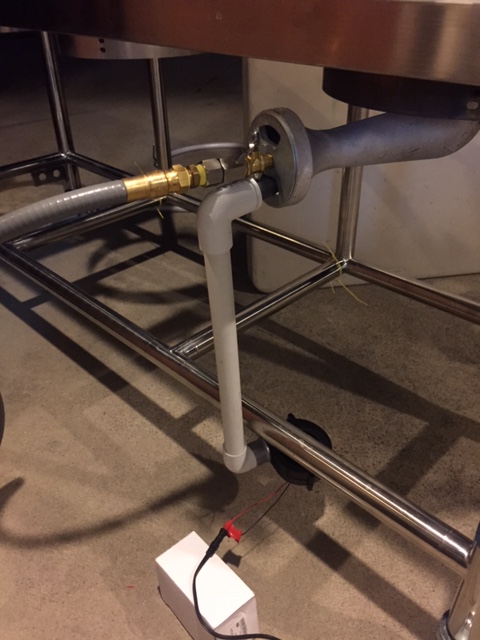

So now the question is, how can I add air assist to my brew rig build. The first thought was I'll just add an SS feed tube to the burner and have an air QD at the bottom of the rig. The only problem with this is that my compressor will cycle on several times during the boil and that is very loud and annoying. My reason for going to the BG14's was to get away from the loud wok/jet burners, so I don't want to replace it with an even louder compressor. As a test, I grabbed my Intek 12V mattress inflator. It puts out good pressure and air volume and it worked like a charm too! It was still a little loud, but now I know I can do this with a smaller fan that can be mounted under my rig. I've ordered up a couple of different ones that I'm now going to play with and see what works.

This is still in the proof of concept phase, but I'm pretty sure I'll be adding forced air at least to my BK burner. Since strike and sparge water don't need to get as hot, I'll likely not do the forced air on those burners since the only real savings might be 10 minutes just to get to strike temp.

Anyone ever play with forced air assist on their brew rig? Any thoughts or suggestions?

Here's a sample of the type of fan I will likely end up using (it puts out 20 CFM):

Here's a couple of pics of the proof of concept tests I was doing:

I should have taken pics or videos of the actual burner flames so you could see how dramatic the difference was. I'll do that and post back here when the other fans arrive.

For my tests, I heated 10 gallons of water for 30 minutes and measured the temperature at 10 minute increments. No matter what burner is used, temperature gains slow the hotter it gets, but I feel a 30 minute test gets things hot enough to judge the effective heating ability.

As a comparison, I did baseline heat tests with my 6", 10 tip wok/jet burners on my old brew stand. Starting at 80 degrees, my wok/jet burners heated, 31, 31 & 28 degrees in the three 10 minute durations. This gave me an even 90 degree rise in 30 minutes.

When I started testing the BG14 burners at different heights, I was only getting 21 degrees rise every 10 minutes for a total of 63 degrees over the whole 30 minutes. When I was looking at the flames on the BG14 burner, there was definite yellowing going on which tells me that it is running rich and there isn't full combustion happening.

I've done tests a few years back with a BG14 and knew it wouldn't be up to the level of the wok burners, but I was pretty surprised at the test results I had just experienced. Other tests I've done didn't have the wind screens, so I know it wasn't really a lack of venting. Knowing that the wok burners perform so much better (50% better) using the same gas hookup tells me that the wok burners are able to burn much more of the available fuel. That means it all comes down to the AFR (air fuel ratio) and being able to get a leaner/hotter burn. So that got me thinking about how to add additional air to the mix to get a full burn out of the available gas. The answer - supercharge it!

As a proof of concept test, I used the air gun from my air compressor and dialed the output pressure down to about 8-10 PSI. When blowing from the air gun, it was just a good light constant flow, but not heavy duty like when you use the air gun to blow or clean things up (which usually is around 80+ PSI). I zip tied the air gun lever to stay on and pushed it into the venturi opening of the BG14 bell housing. HOLY **** is all I can say! Every tip on the BG14 was burning solid blue at about 1" in height. This baby was putting out serious BTU's now!

So, time to re-do the 10 gallon heat test. The first 10 minute segment gave me a 42 degree rise!!! The second 10 minutes was 38 degrees and the 3rd one was 30 degrees (remember, the hotter it gets, the lower the rise per minute). That was 110 degrees in 30 minutes - compared to the 63 degree rise without air assist. Gas flow was the same between the tests, only the addition of forced air was different. That's a 75% increase in BTU output by just feeding air into the venturi!

So now the question is, how can I add air assist to my brew rig build. The first thought was I'll just add an SS feed tube to the burner and have an air QD at the bottom of the rig. The only problem with this is that my compressor will cycle on several times during the boil and that is very loud and annoying. My reason for going to the BG14's was to get away from the loud wok/jet burners, so I don't want to replace it with an even louder compressor. As a test, I grabbed my Intek 12V mattress inflator. It puts out good pressure and air volume and it worked like a charm too! It was still a little loud, but now I know I can do this with a smaller fan that can be mounted under my rig. I've ordered up a couple of different ones that I'm now going to play with and see what works.

This is still in the proof of concept phase, but I'm pretty sure I'll be adding forced air at least to my BK burner. Since strike and sparge water don't need to get as hot, I'll likely not do the forced air on those burners since the only real savings might be 10 minutes just to get to strike temp.

Anyone ever play with forced air assist on their brew rig? Any thoughts or suggestions?

Here's a sample of the type of fan I will likely end up using (it puts out 20 CFM):

Here's a couple of pics of the proof of concept tests I was doing:

I should have taken pics or videos of the actual burner flames so you could see how dramatic the difference was. I'll do that and post back here when the other fans arrive.