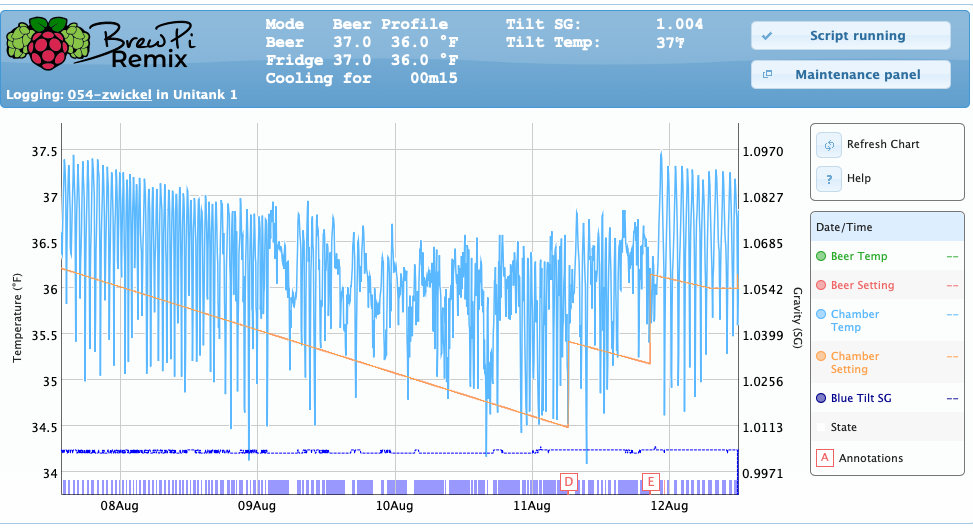

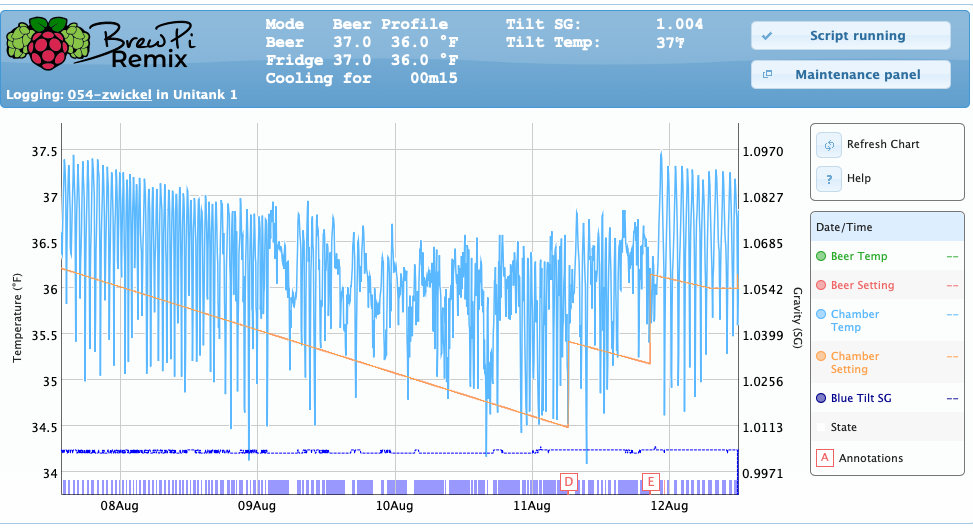

I had a "doh" moment after listening to this week's Master Brewer's podcast (Episode 286: Fluid for Though). I have a 7 gal SSBrewtech Unitank that I use for making lagers. I use a fermentation schedule that I got from an interview with the owners of Bierstadt Lagerhaus in Denver that starts at 47F, holds for a week, ramps down to 40F, holds for a week, and then ramps down to 34F to go into a keg for lagering at 30F. My temperatures have always gone crazy towards the end of fermentation. When the temperature is above 36F, the cooling cycle is normal. On the graph below, you can see that there's normal on/off cooling with a regular period until August 9 when the set point hits 35.5F. Then the graph goes crazy with the cooling on for extended periods of time.

Water's density increases as it cools until around 4C (39F) when the density starts to decrease. (Ice floats!) This means that if you're cooling the beer from the top but measuring the temperature near the bottom, as is the case of the SSBT unitank, you get thermal inversion. The cooler beer (<39F) at the top is no longer less dense than the warmer beer beneath it (>39F) so convection shuts off and the liquid does not mix. Conduction was still transporting some heat, but that's not nearly as efficient as convection.

The podcast discussed a bunch of interesting aspects of fluid dynamics, but when they discussed thermal inversion, I figured that must be what is going on. Sure enough, my tilt at the top of the fermenter is reading 28F but the probe is reading 36F with a set point of 34F and the glycol pump is on.

When I bumped up the set point up to 36F, convection started again and the loop functions normally. The solution for commercial brewers is that you need glycol cooling around the cone of the fermenter, not just the top. For me, I guess I can only cool to 36F and then I have to keg and put in the lagering keezer with an ambient of 30F.

Water's density increases as it cools until around 4C (39F) when the density starts to decrease. (Ice floats!) This means that if you're cooling the beer from the top but measuring the temperature near the bottom, as is the case of the SSBT unitank, you get thermal inversion. The cooler beer (<39F) at the top is no longer less dense than the warmer beer beneath it (>39F) so convection shuts off and the liquid does not mix. Conduction was still transporting some heat, but that's not nearly as efficient as convection.

The podcast discussed a bunch of interesting aspects of fluid dynamics, but when they discussed thermal inversion, I figured that must be what is going on. Sure enough, my tilt at the top of the fermenter is reading 28F but the probe is reading 36F with a set point of 34F and the glycol pump is on.

When I bumped up the set point up to 36F, convection started again and the loop functions normally. The solution for commercial brewers is that you need glycol cooling around the cone of the fermenter, not just the top. For me, I guess I can only cool to 36F and then I have to keg and put in the lagering keezer with an ambient of 30F.