rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 776

- Reaction score

- 175

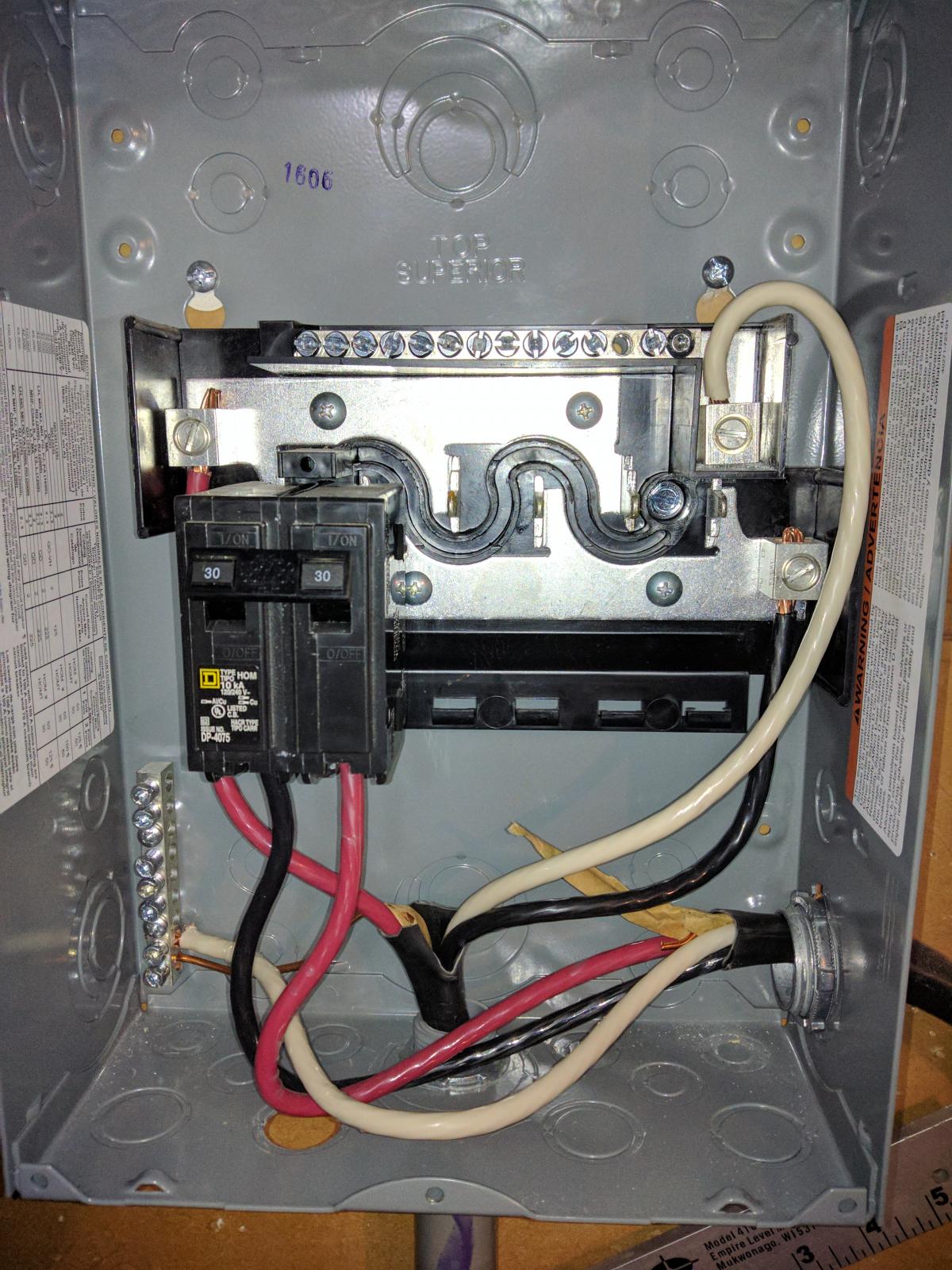

I'm ready to wire in my spa panel. I'm mounting this in my garage, next to my already-existing sub-panel for my welder (on the left).

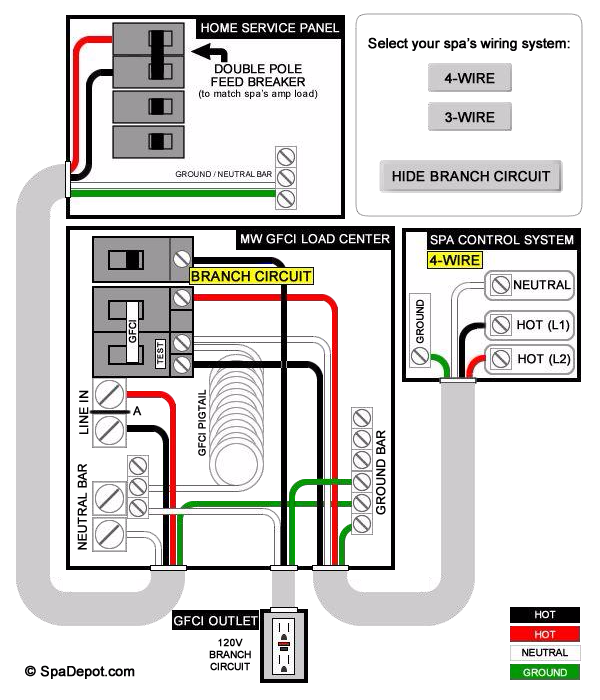

Question: How should I run power to the Spa panel?

The power feed to the welder sub-panel is run off a 60A/240v circuit breaker from the house panel.

Here's a picture:

Question: How should I run power to the Spa panel?

- Should I just take it from the outlet I plug my welder into (though that's on only a 30A/240v breaker and the Spa breaker is a GFCI 50A/240v)?

- Or, should I add another breaker in the welder sub-panel and then run that power over to the Spa Panel?

- Or, can I somehow tap into the feed from the main house panel to the sub-panel and also run that over to the Spa panel?

The power feed to the welder sub-panel is run off a 60A/240v circuit breaker from the house panel.

Here's a picture: