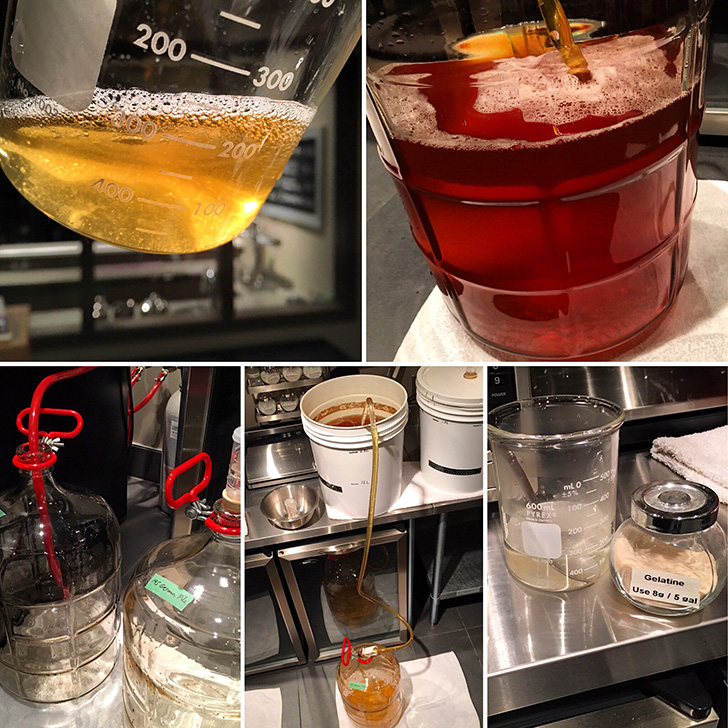

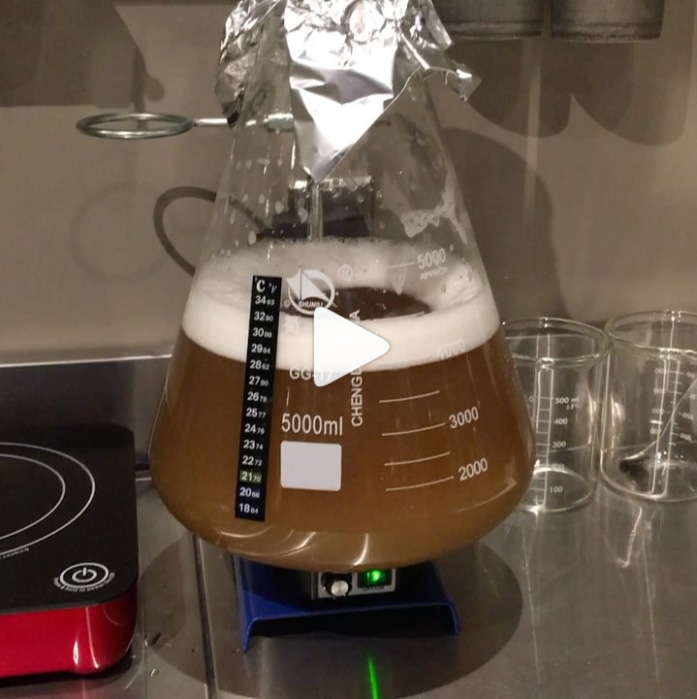

This past weekend I brewed a Deschutes Fresh Squeezed clone - here are some pics from that brew day. Have any recent brew day pics?

Grinding 30lbs of grain:

IMG_0346 by jonymac, on Flickr

IMG_0346 by jonymac, on Flickr

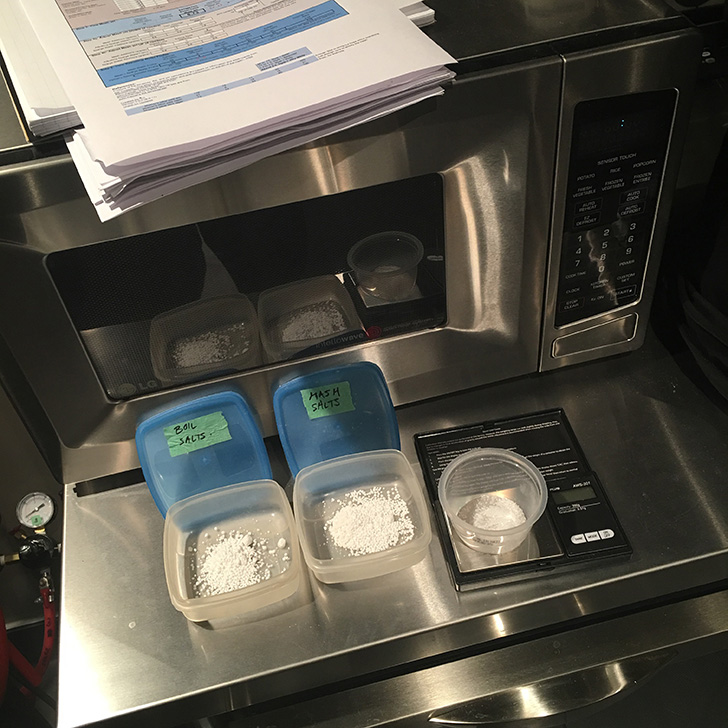

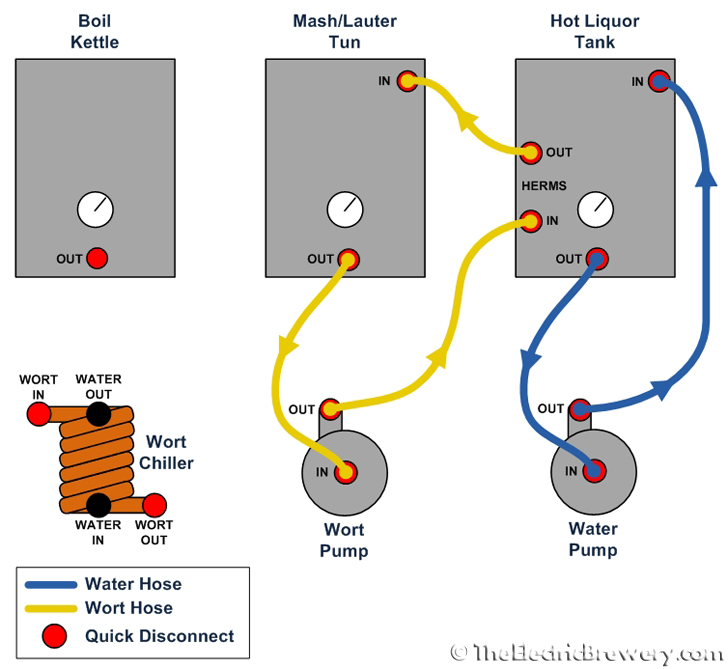

Hoses hooked up and filling HLT:

IMG_0345 by jonymac, on Flickr

IMG_0345 by jonymac, on Flickr

My buddies waxing philosophic at the end of brew day:

IMG_0350 by jonymac, on Flickr

IMG_0350 by jonymac, on Flickr

Grinding 30lbs of grain:

IMG_0346 by jonymac, on Flickr

IMG_0346 by jonymac, on FlickrHoses hooked up and filling HLT:

IMG_0345 by jonymac, on Flickr

IMG_0345 by jonymac, on FlickrMy buddies waxing philosophic at the end of brew day:

IMG_0350 by jonymac, on Flickr

IMG_0350 by jonymac, on Flickr