Homercidal, I'd really like to see some pics!

I had recorded a video of it working, but now it's lost. Next time I get out to the garage to use it I'll take pics and maybe some video on my phone or something.

Homercidal, I'd really like to see some pics!

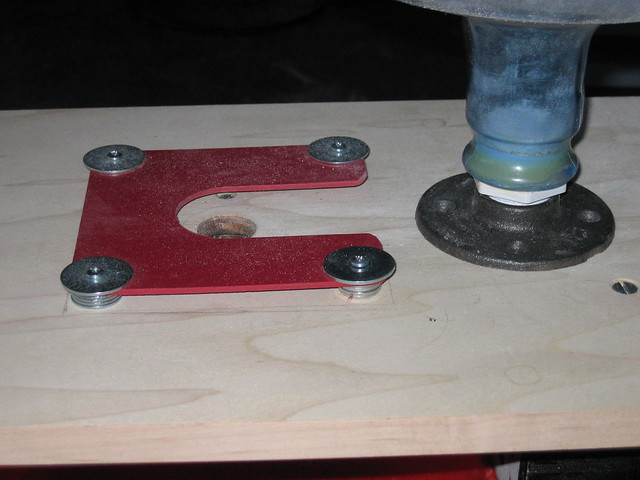

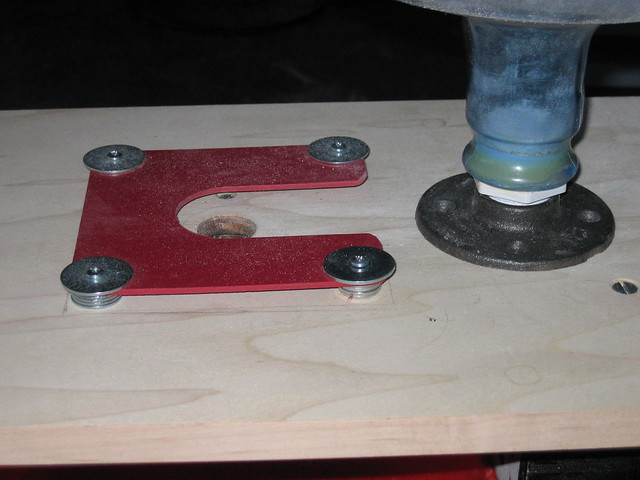

Here is What I did with my Monster Mill.

I have just finished and have not run my first batch yet.

http://my.imageshack.us/v_images.php

I agree that 200 is probably about ideal. The 172 would also be near perfect IMO. I see no advantage in going slower than that. The dust will be minimal even at 200 and especially so if you condition the malt prior to milling, which is what I always do. There will be a difference in the crush with different mill speeds, but that can easily be compensated for through gap adjustment. It would require a substantial jump in the rpms to make a noticeable difference in the crush, but you could tell if you ran a mill at say 100 vs 600 with the same gap. The higher speed will produce a finer crush. I'm not exactly sure why this happens, but I got that information directly from a guy who once designed malt mills and he did some actual sieve analysis testing on the grist produced at various speeds specifically to see what effect the speed changes would have.

IMO, milling relatively slowly is desirable for several reasons. Less wear and tear on the mill, generates much less grain dust and it's quieter. I'm running quite slow myself at only 115 rpm and about 2+ lbs/min throughput. The slow rate is not even an inconvenience as I can fill the hopper and do something else while the mill is running. I just milled a 50 lb grain bill a few days ago in about 20 minutes. I didn't actually time it, but it did not take very long. I was headed to a group brew that morning. The hopper holds about 20 lbs, so I only had to fill it twice and top it up with the remainder near the end. It was finished milling before I had the snow swept off my truck. The usual problem is getting the mill to run slower, not faster.

Here is a new link to my pic's

http://s1239.photobucket.com/albums/ff508/BeerDino/

Thanks for the welcome. I have been an extract brewer for the last 2 years and am 1 more batch from the start of my all grain adventures.

Like most of us I have been slowly compiling the nessasary parts to make the transition, and as we all know you can never have enough toys.

Catt, what mill and gearmotor you using for 115 rpm output?

I scored a brand new Bodine parallel shaft AC gearmotor. I have a Phil Mill I which is no longer in production. Too bad as it is a very good mill. I got the gearmotor for almost nothing. It produces 68 inch-lbs of torgue and it's nearly unstoppable. I hooked it up with the Lovejoy spider couplings for a direct drive arrangement. i particularly like this mill because you can adjust the gap while it is in operation with the turn of a thumb screw. This makes it very fast, easy and convenient when dialing in the crush. I do this visually. No tools or feeler gauges needed.

IMO, milling relatively slowly is desirable for several reasons. Less wear and tear on the mill, generates much less grain dust and it's quieter. I'm running quite slow myself at only 115 rpm and about 2+ lbs/min throughput. The usual problem is getting the mill to run slower, not faster.

Enter your email address to join: