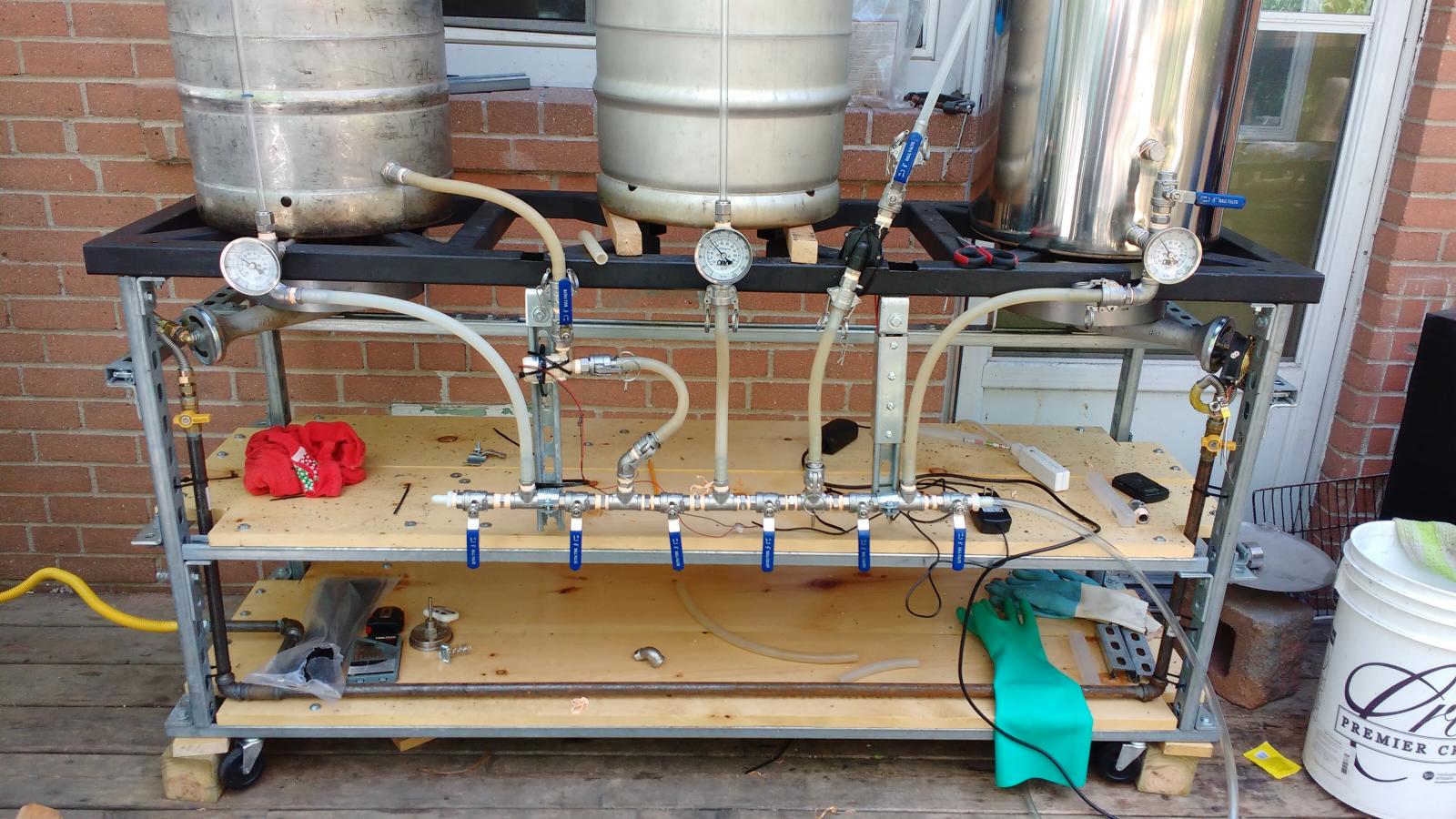

This design is the culmination of all the know how I've gained from spending a frankly irresponsible amount of time in this board. Big thanks for inspiration go to Kal, BlackHeart, JonW, AugieDoggy, and several others. I can't claim any real originality here - I've just ripped off the best ideas I've found throughout the board.

I got so excited that I couldn't hold back. This post is premature as I'm not done building it yet. I'll be adding pictures as it comes together.

Basic stats and design goals:

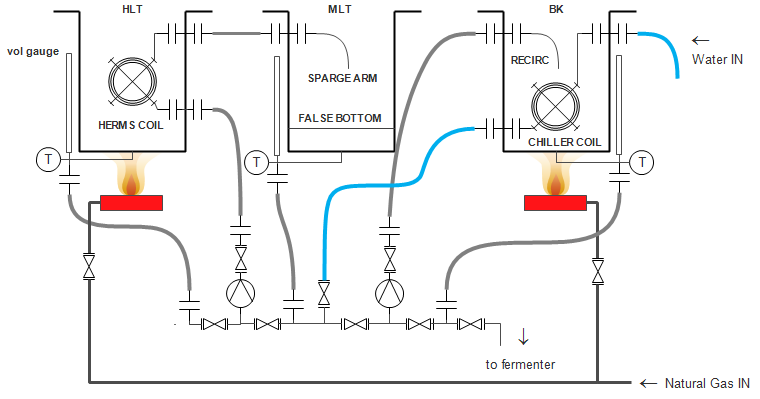

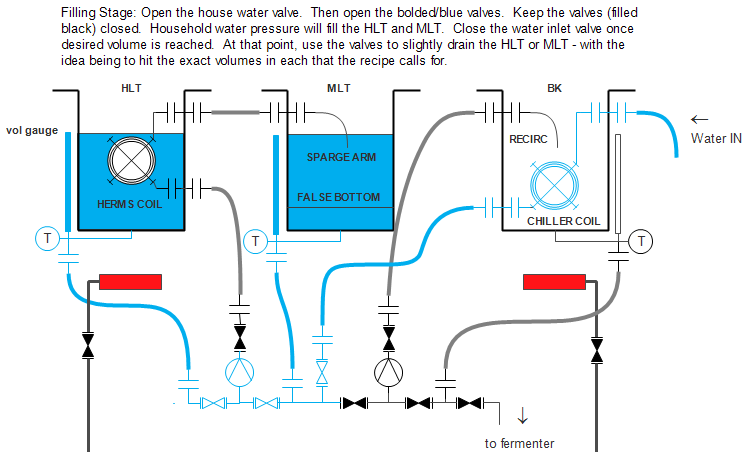

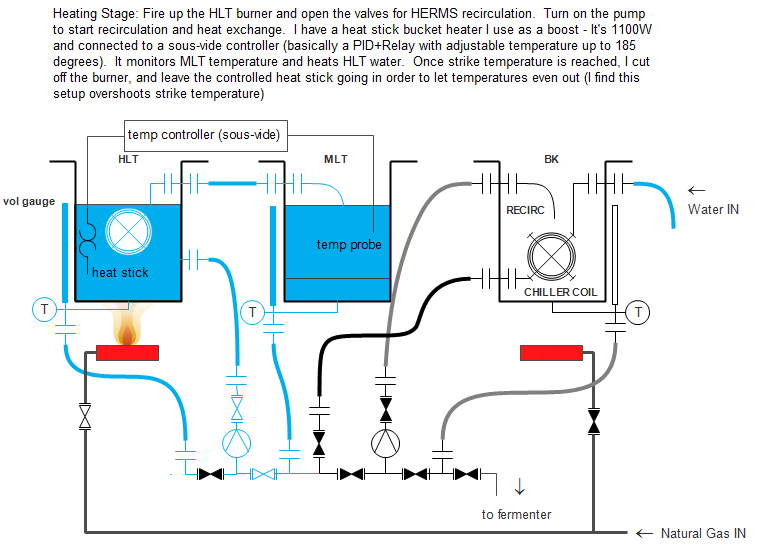

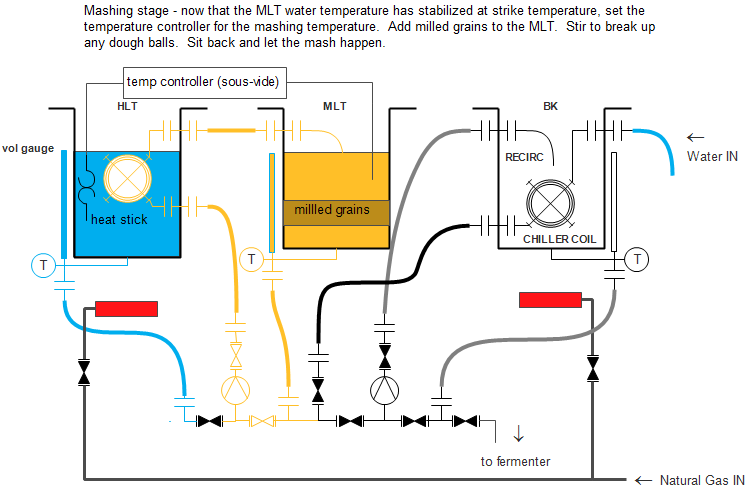

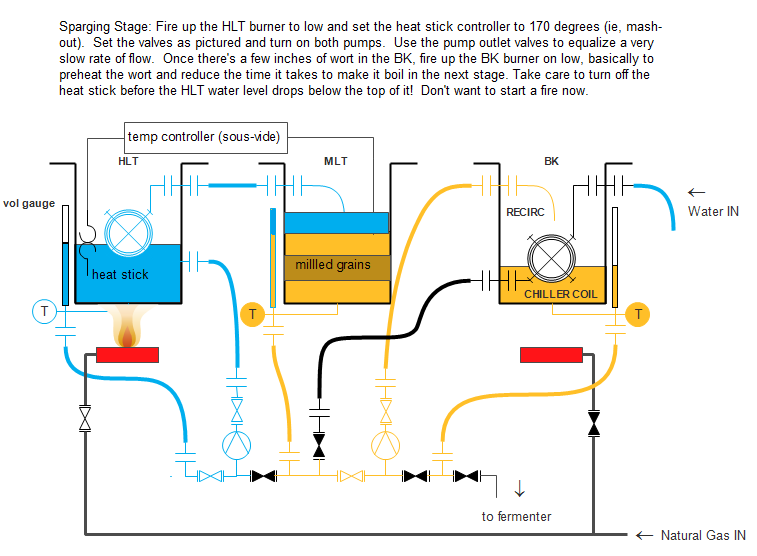

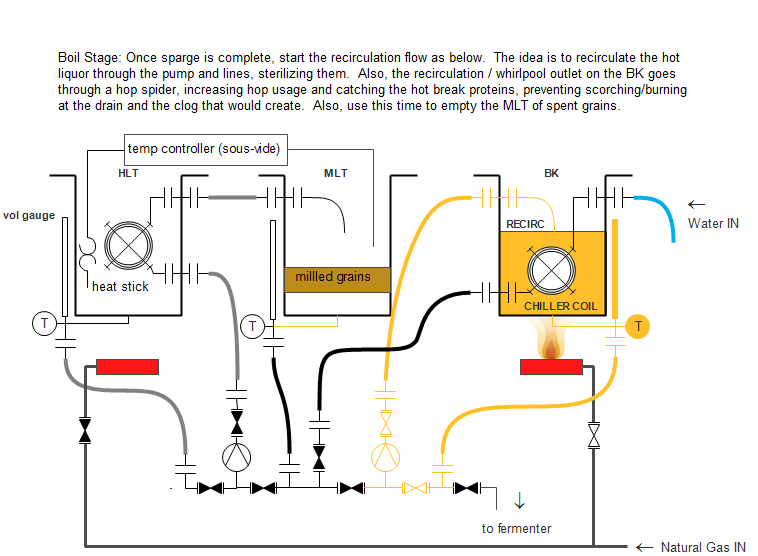

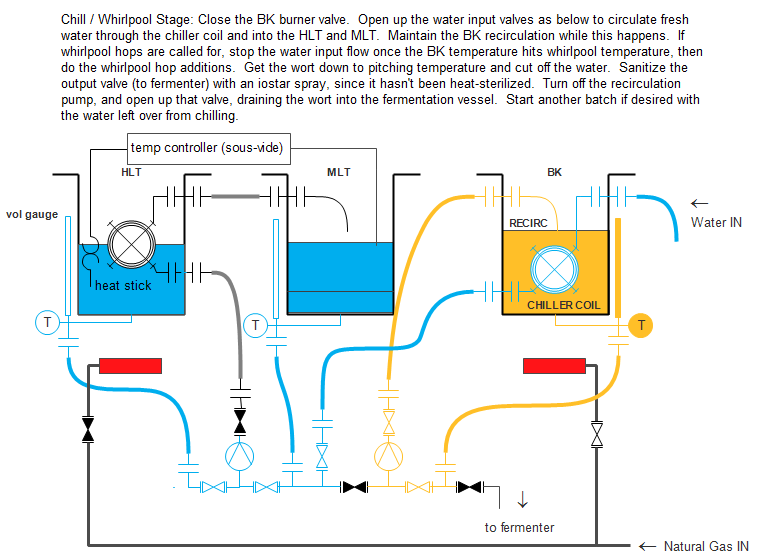

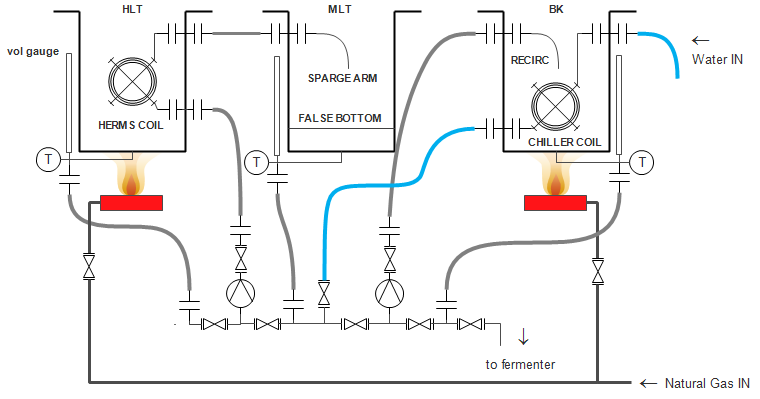

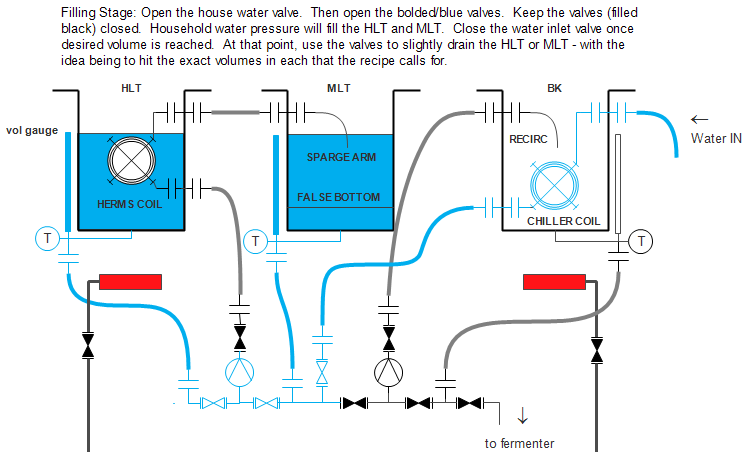

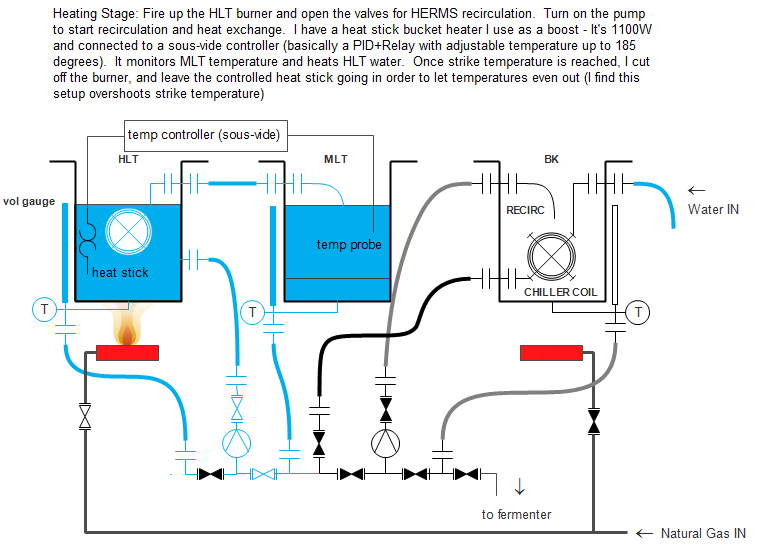

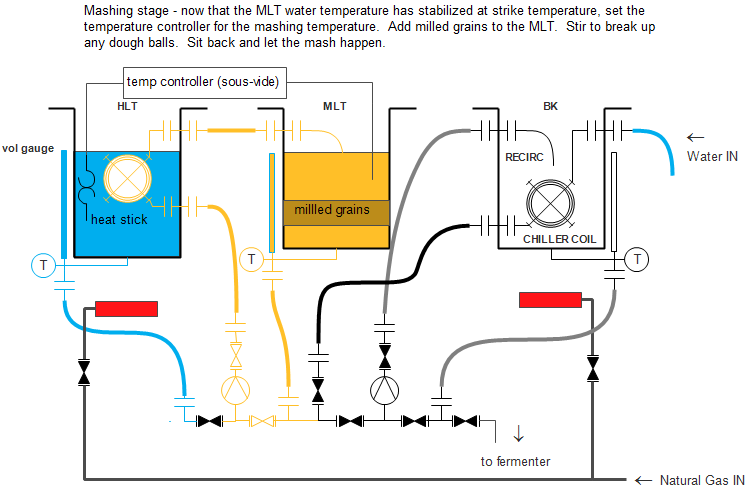

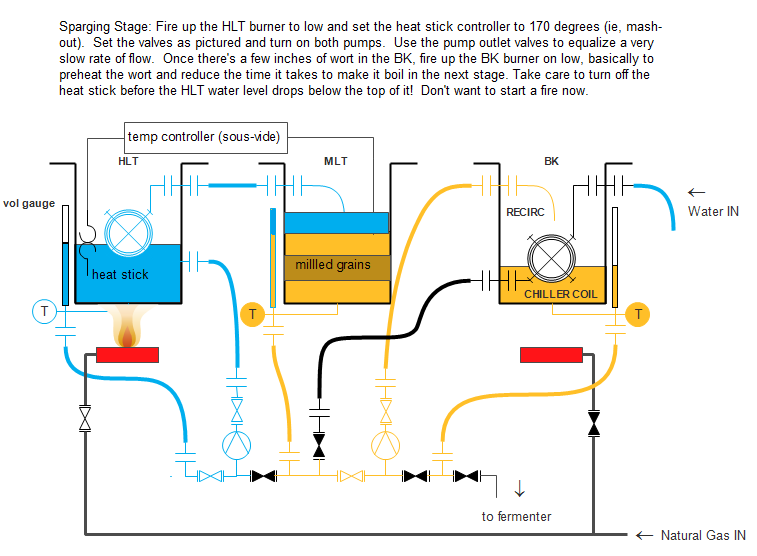

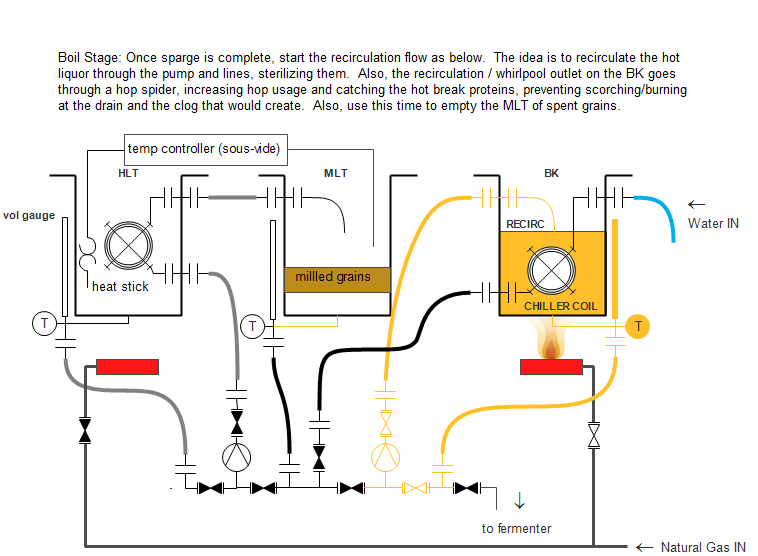

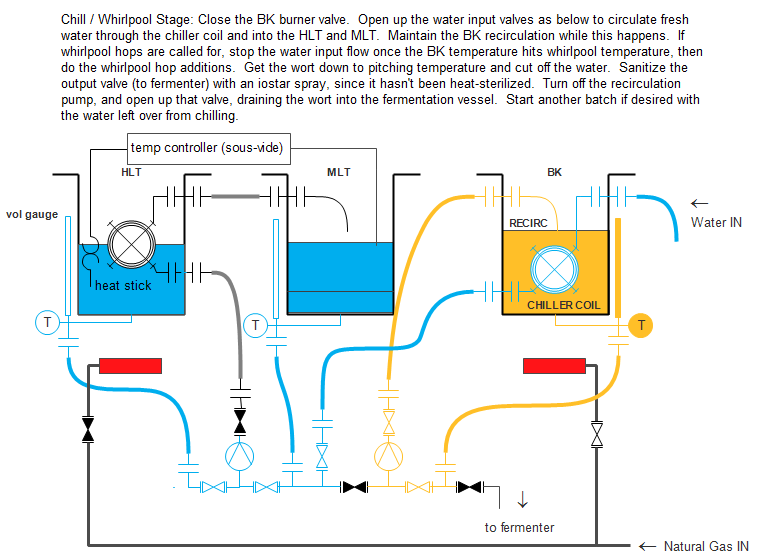

Update: attached the plumbing diagram and various stages.

I got so excited that I couldn't hold back. This post is premature as I'm not done building it yet. I'll be adding pictures as it comes together.

Basic stats and design goals:

- 3 bottom draining keggles - can clean in place

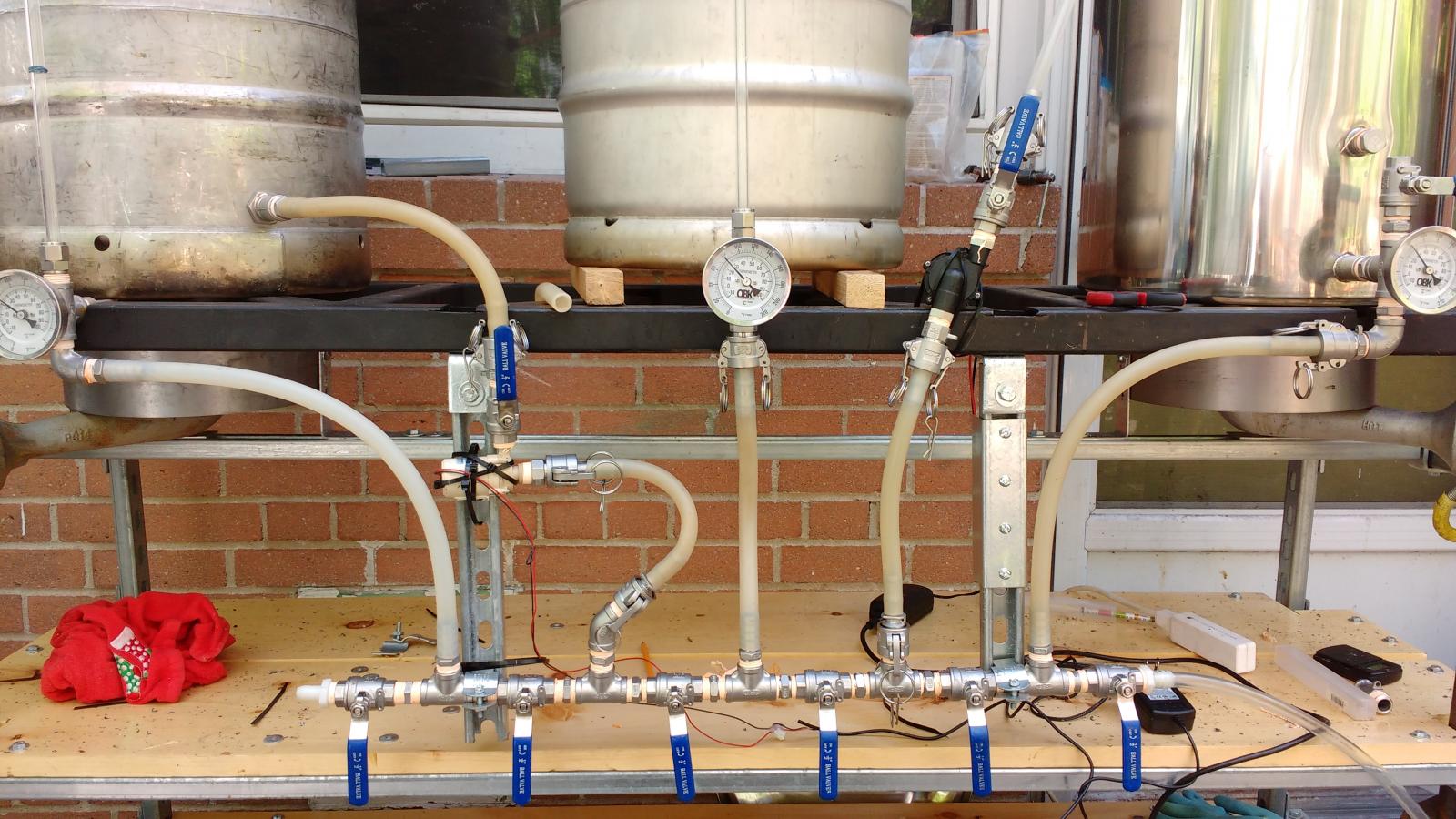

- liquid control via hard-plumbed manifold - no swapping hoses for sparging

- fueled by natural gas - no swapping propane tanks

- portal heat stick and sous-vide controller - precise mash control without expensive electrical work

- single tier channel strut stand, approx 3' tall - no bending or crouching to control valves, and can store keggles securely within the structure for transport

- water source "built-in" via the chiller coil - no more lifting buckets of water

- liquid flow logic so simple, it is clean on a 2D drawing (so close!)

Update: attached the plumbing diagram and various stages.