You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Carolina SC midlands area brewers

- Thread starter SHAIV

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

Hmmmm. I think i might get some. I can just clean everything real good then use iodophor then rinse real good, and dry, then sanitize with new star san before use again. Better than using bleach or replacing everything probably

Cheesy_Goodness

Well-Known Member

Anyone ever do the Columbia Brew Bus? We were gifted some tickets recently and went out on Saturday. Stopped at 3 breweries (in our case it was Columbia Craft, Swamp Cabbage, and Hunter Gatherer) and got 4 generous samples (I honestly think they were close to a half pint each) at each stop and a tour of the brew house.

TravelingLight

Well-Known Member

Haven't done it, but they've been around a while and seem to be doing pretty well. Obviously the more breweries we get the better their tours are, I assume.Anyone ever do the Columbia Brew Bus? We were gifted some tickets recently and went out on Saturday. Stopped at 3 breweries (in our case it was Columbia Craft, Swamp Cabbage, and Hunter Gatherer) and got 4 generous samples (I honestly think they were close to a half pint each) at each stop and a tour of the brew house.

Cheesy_Goodness

Well-Known Member

That would seem right. They apparently started out when there was just three so they would hit them all, but now they go to a set two depending on the day, and the third one is picked by the people on the bus. It's $45 a ticket so it isn't cheap but I'd do it again if any beer loving friends from out of town come to the area.

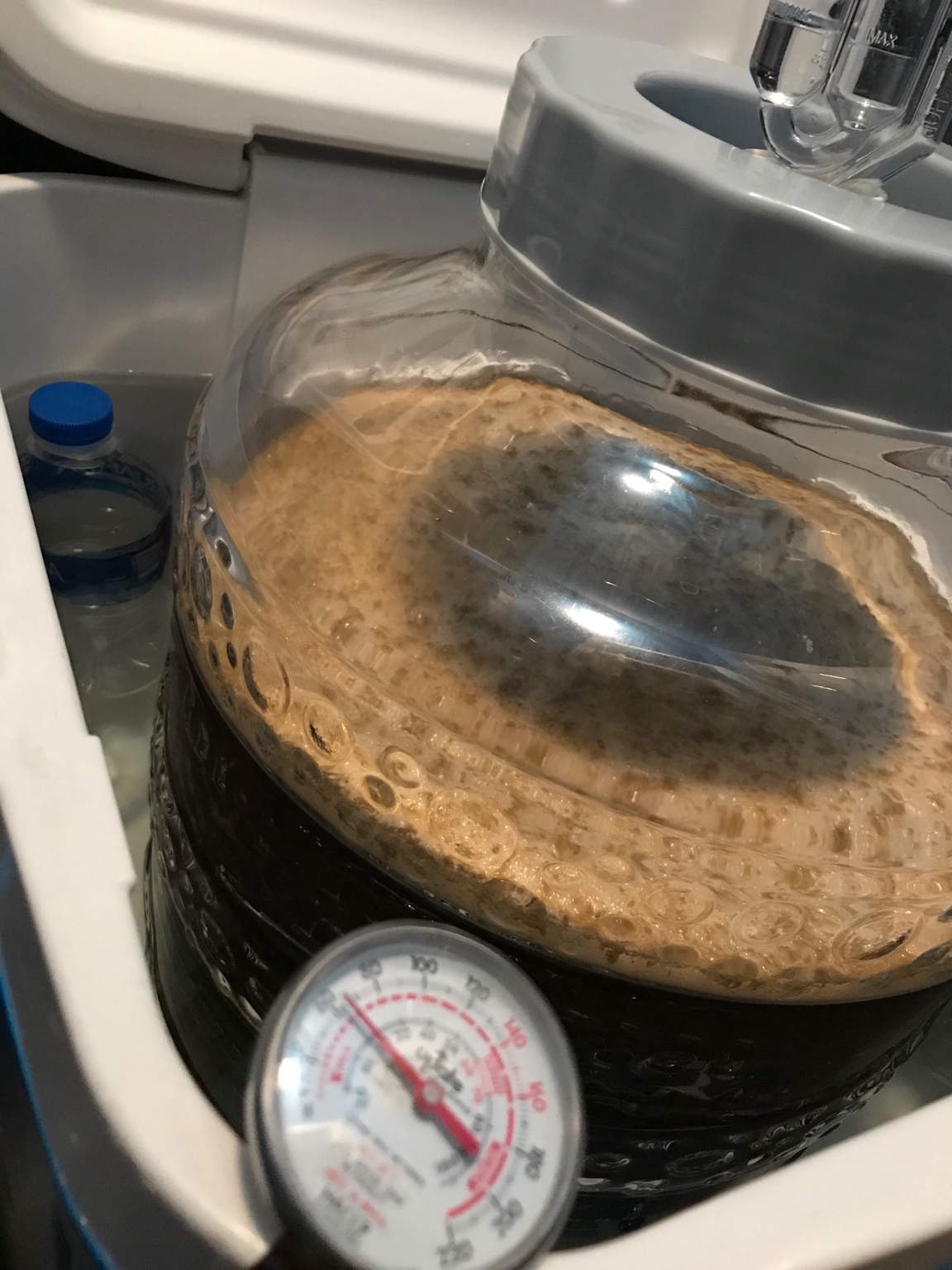

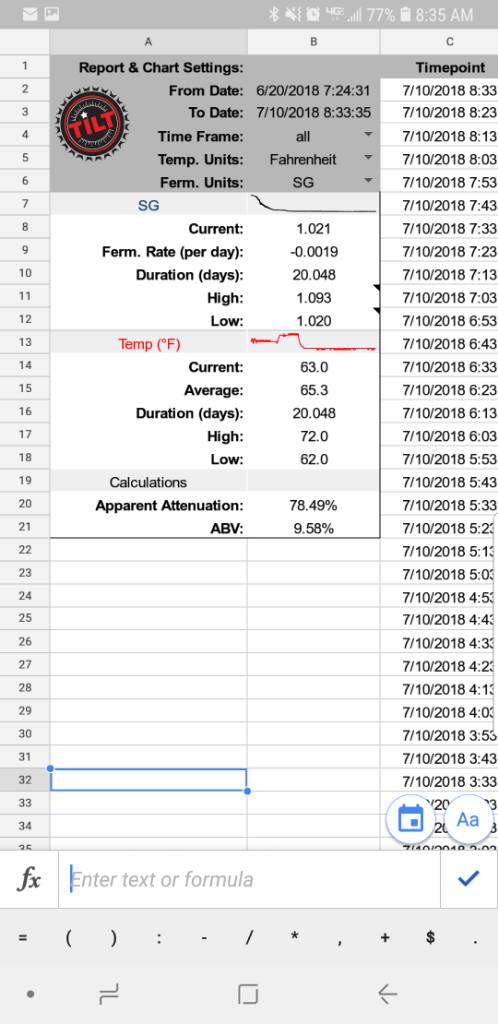

A little late to this conversation, but we recently brewed a RIS using WLP090. OG was 1.093 and it dropped down to 1.026 in 4 days. Temp was 67°. It stayed there for 2 days and I bumped the temp up to 71° and also gave the yeast a bit of a rousing by using a long spoon and gently stiring the bottom for about 10 seconds.Overall, looks pretty good to me...

I've only used WLP090 once, on the recent pale that I used. Any reason why you want to use that one? Just curious, I would have never figured it for a dark beer. BUT, it's definitely aggressive and pretty damn neutral, low in esters, so I actually think it might work well and allow the malt, bourbon, and oak to shine. FWIW, I got 79% AA with 090, in the starter and in the beer. Ergo, if you get 79% AA, it won't finish as low as 1.012, probably closer to 1.019ish?? I no math. But you may get more attenuation, the only time I used it I fermented at ambient temps.

I think you'll be fine with those hops. I honestly don't give a whole lot of thought into my hop bill for stouts (except I ain't putting mosaic or some shiit like that in a stout). I pretty much bounce between nugget and magnum for bittering anyway.

Bourbon process looks sound as well. I did not do the dump and re-soak, but I actually really like that idea. I suspect (dunno for certain) you might lose a little of the oaky tannins by dumping and re-soaking, but I could be wrong. Are you soaking the wood chunk in bourbon prior to putting it in the beer? Or is it a chunk from a fresh barrel? Looking back at my (2 year old) notes, I added some of the actual liquid bourbon from the oak spiral "marinade" to the bottling bucket. I did it to taste, but that was very early in my homebrewing tenure and I did it kind of half-assed.

Finally, great call on the 3+ months bottle conditioning. Of course, that will smooth out any of the hot alcohol. But I also remember mine taking forever to carb up in the bottle. That was actually the only batch I ever bottled the whole thing with priming sugar and all and it took forever to carb up. Just the extended aging on the oak/bourbon knocked back some of the yeast. Plus adding some of the bourbon to the bottling bucket probably hindered it as well, to some extent.

It dropped to 1.021 over the next two days.

I got 78.5% attenuation.

I then bumped the temp down to 65° to let it condition on the yeast for 2 1/2 weeks.

We'll bottle it this week and let it age until the winter.

As for why I went with the 090.. I wanted to start overbuilding my yeast starters to start haversting to save money. WLP090 is known to be a fast and clean yeast and I figure I can use it for 90% of what I brew.

I built a 2L starter originally with this yeast, crashed it, decanted it and built another 1.5L starter. First step gave me 211 billion cells, 2nd gave me 423 billion.

I pitched 3/4 of this and saved 1/4 of it.

I just made a new starter yesterday from what I harvested to use this weekend. I'll need to step it up one more time so I can harvest it again since we are brewing another RIS.

I basically used Brulosophy's method here:

http://brulosophy.com/methods/yeast-harvesting/

I used the calculator that is linked in that article to know how much to make.

Last edited:

TravelingLight

Well-Known Member

Shouldn't that be 211 billion cells? Or did I misunderstand you?A little late to this conversation, but we recently brewed a RIS using WLP090. OG was 1.093 and it dropped down to 1.026 in 4 days. Temp was 67°. It stayed there for 2 days and I bumped the temp up to 71° and also gave the yeast a bit of a rousing by using a long spoon and gently stiring the bottom for about 10 seconds.

It dropped to 1.021 over the next two days.

I got 78.5% attenuation.

I then bumped the temp down to 65° to let it condition on the yeast for 2 1/2 weeks.

We'll bottle it this week and let it age until the winter.

As for why I went with the 090.. I wanted to start overbuilding my yeast starters to start haversting to save money. WLP090 is known to be a fast and clean yeast and I figure I can use it for 90% of what I brew.

I built a 2L starter originally with this yeast, crashed it, decanted it and built another 1.5L starter. First step gave me 211 million cells, 2nd gave me 423 million.

I pitched 3/4 of this and saved 1/4 of it.

I just made a new starter yesterday from what I harvested to use this weekend. I'll need to step it up one more time so I can harvest it again since we are brewing another RIS.

I basically used Brulosophy's method here:

http://brulosophy.com/methods/yeast-harvesting/

I used the calculator that is linked in that article to know how much to make.

I never step up my harvested yeasts, I put them straight into a 2L starter with no issues. I also follow Brulosopher's method with one caveat. I don't do the long term storage under a bed of sterile/deoxygenated water. I dump off 500ml into a pint jar, let that crash out, decant, and store the slurry in centrifuge tubes. Brulosopher has mentioned that he doesn't even do the water in the jars anymore. Cheers brother.

Yes, sorry Billion cells.Shouldn't that be 211 billion cells? Or did I misunderstand you?

I never step up my harvested yeasts, I put them straight into a 2L starter with no issues. I also follow Brulosopher's method with one caveat. I don't do the long term storage under a bed of sterile/deoxygenated water. I dump off 500ml into a pint jar, let that crash out, decant, and store the slurry in centrifuge tubes. Brulosopher has mentioned that he doesn't even do the water in the jars anymore. Cheers brother.

I only stepped up this starter because it was such a big beer. If I would have only done the 2L starter I would only have enough for the brew and not enough to harvest.

I just store in pint mason jars. Won't ever have more than a couple and there is a drawer in my beer fridge where they fit nicely.

I thought brulosophy kept his under the starter beer until pitch/starter time, as the alcohol in theory makes it harder for any infection to step in.

I'm jealous of your 4 day attenuation; mine hit ~1.036 before I left for training. Real curious what three-six weeks on the cake will do to my stout; I did a sugar addition to bring total OG up to 1.096 about 5 days in (about 10 oz into my 5 gallon carboy, 5 oz into my 2.5 gallon batch) to hopefully cause an uptick in fermentation and dry it out a hair more.

I'm jealous of your 4 day attenuation; mine hit ~1.036 before I left for training. Real curious what three-six weeks on the cake will do to my stout; I did a sugar addition to bring total OG up to 1.096 about 5 days in (about 10 oz into my 5 gallon carboy, 5 oz into my 2.5 gallon batch) to hopefully cause an uptick in fermentation and dry it out a hair more.

He does. That's what I do. I run the starter for 2 days and then separate it into pint jars. I then crash it in the fridge and leave it like that until I am ready to pitch it or create another starter. TL decants his after crashing and puts the slurry into vials for storage. I assume he does this to save space in his fridge. Either way should work. You can also freeze the vials if you wish, but there is more involved with that including adding glycerin.I thought brulosophy kept his under the starter beer until pitch/starter time, as the alcohol in theory makes it harder for any infection to step in.

I'm jealous of your 4 day attenuation; mine hit ~1.036 before I left for training. Real curious what three-six weeks on the cake will do to my stout; I did a sugar addition to bring total OG up to 1.096 about 5 days in (about 10 oz into my 5 gallon carboy, 5 oz into my 2.5 gallon batch) to hopefully cause an uptick in fermentation and dry it out a hair more.

TravelingLight

Well-Known Member

Yep, absolutely a space issue. I save a lot of dregs from mixed ferm beers as well, so my fridge was quickly becoming dominated by half pint mason jars. Now I have about 40 different strains (sacc and mixed culture) in two small centrifuge tube racks (but I am in need of some spring cleaning to cull out some stuff I don't need anymore).He does. That's what I do. I run the starter for 2 days and then separate it into pint jars. I then crash it in the fridge and leave it like that until I am ready to pitch it or create another starter. TL decants his after crashing and puts the slurry into vials for storage. I assume he does this to save space in his fridge. Either way should work. You can also freeze the vials if you wish, but there is more involved with that including adding glycerin.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

Its no-rinse at lower concentrations; I use it so that I can use Belgian yeast without needing to worry about an Saccharomyces cerevisiae var. diastaticus infection ruining future non-Belgian batches.

So i tried out some io star iodophor last night and soaked two glass carboys in it. I just got a new racking cane as well so i thought, Lets transfer with my old(partially cracked) cane. I felt like i had to be careful not to spill it to keep from staining anything. It stained the old vinyl tubing on my racking cane but not the cane itself. Is there anything i should be careful of with iodophor? I was probably just being overly cautious but idk. I know the staining isnt an issue just not pleasing to the eye

What ratio did you use? I usually to the 1 teaspoon/1.5 gallons ratio, and use it as a no-rinse at that concentration (generally because I don't want to deal with starsan's foaming). It shouldn't have stained the tubing; I only get stains in my buckets when I leave it in for literally days until the iodine denatures (water turns clear). It should be used with cool water only (not that I know why).

I guess the downsides are a) staining and b) it is a rinse-sanitizer at high levels, otherwise I'm unaware of any downsides. The staining does fade with time.

I guess the downsides are a) staining and b) it is a rinse-sanitizer at high levels, otherwise I'm unaware of any downsides. The staining does fade with time.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

I did the recommended 1 oz to 5 gal. Can you use it on anything? I like the fact that it can kill more. Another downside is the 1 min contact time. Where star san is a 30 sec contact time. Thats why im so appalled when people use spray bottles only. How do you cover everything for 30 sec - 1 min or more with spray only? Somewhere i read something about trying to do 5 min contact time but cant remember if that was star san or iodophore. Either way its not really a problem just more time consuming maybe

TIL that starsan is 2 minutes:

https://www.reddit.com/r/Homebrewing/comments/sikpj/finally_here_are_five_star_chemicals_answers_to/

Idophor is a substitute for starsan; I'm unaware of any downsides to using it over starsan other than that it breaks down sooner (day or two) and can stain. The only other downside I can think of is that idophor should be drained from fermenters/kegs if used as a primary sanitizer, whereas you can directly rack your beer into a foam-filled star-sanned vessel without issue.

https://www.reddit.com/r/Homebrewing/comments/sikpj/finally_here_are_five_star_chemicals_answers_to/

Finally, if something is wet with Starsan, is it assumed its sanitized (for example, if I wet my thermometer and then put it in the wort)? Or does it need to be wet for a short period of time to kill the bacteria? Answer: It should have a contact time of at least 2min to fully do the job.

I'm under the impression that contact time is literally "time from contact," and not "constant spray/soak of solution," so waiting 30 seconds/2 minutes/whatever is sufficient time.

Idophor is a substitute for starsan; I'm unaware of any downsides to using it over starsan other than that it breaks down sooner (day or two) and can stain. The only other downside I can think of is that idophor should be drained from fermenters/kegs if used as a primary sanitizer, whereas you can directly rack your beer into a foam-filled star-sanned vessel without issue.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

Ok so i ordered some cryo hops from amazon the other day. I received them yesterday and i dry hopped a session ipa with them then i went to smell the pouch they came in and it smelled like its probably old. It didnt smell like hops at all really. Ive used these before and they smelled great before even after they sat in my freezer for a while after receiving them. Is my beer gonna be bad now? Im like i have no idea what the effects from this is going to be. Ive already reported it to amazon and got my money back. They said they will investigate it but is my beer ruined now?

TravelingLight

Well-Known Member

Sorry fellas, I need to rant a bit...

We went down to Conquest the other day for a couple beers with a fellow PSB'er. They had their new peach sour on the board. Sweet! I've had a few damn solid sours from Conquest, but they're always few and far between, so I was excited to see something new and I assumed it was one of the beers that's been in a barrel for sometime. I ordered it and Jeff warned me that it was very sour. I assured him I love the pucker factor. Beer comes out. Looks good. So I dive in for a smell. GOOD. GOD. The vinegar. Like, straight up malt vinegar. (ETA: Brettanomyces can get very acetic in the presence of oxygen, for those who never work with brett) I still tasted it. It was absolutely horrible. I'm talking, one of the worst beers I've ever had. It was massively oxidized because it tasted like I was drinking malt vinegar with a hint of peach extract. Why in God's name would you put that out? I can totally appreciate some acetic notes in a sour. Often times it's a nice compliment. But this beer was entirely acetic acid. I don't even think they could have blended this out, without something like a 95:5 blend. I couldn't finish it. This is the worst beer Conquest has ever brewed, bar none. /rant over

We went down to Conquest the other day for a couple beers with a fellow PSB'er. They had their new peach sour on the board. Sweet! I've had a few damn solid sours from Conquest, but they're always few and far between, so I was excited to see something new and I assumed it was one of the beers that's been in a barrel for sometime. I ordered it and Jeff warned me that it was very sour. I assured him I love the pucker factor. Beer comes out. Looks good. So I dive in for a smell. GOOD. GOD. The vinegar. Like, straight up malt vinegar. (ETA: Brettanomyces can get very acetic in the presence of oxygen, for those who never work with brett) I still tasted it. It was absolutely horrible. I'm talking, one of the worst beers I've ever had. It was massively oxidized because it tasted like I was drinking malt vinegar with a hint of peach extract. Why in God's name would you put that out? I can totally appreciate some acetic notes in a sour. Often times it's a nice compliment. But this beer was entirely acetic acid. I don't even think they could have blended this out, without something like a 95:5 blend. I couldn't finish it. This is the worst beer Conquest has ever brewed, bar none. /rant over

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

That sucks man. Now you know how i feel about sours! Lol jk. I tried a key lime pie gose by westbrook on july 4th and i was like, “I think i could drink that” not that i would search for it and buy it but if someone gave me one Id hit it. Lol

TravelingLight

Well-Known Member

Yeah dude, I get it. Sours definitely aren't for everyone. And I'm not one to yuck another man's yum. But this was just freaking awful bad. I love sours and this was terrible.That sucks man. Now you know how i feel about sours! Lol jk. I tried a key lime pie gose by westbrook on july 4th and i was like, “I think i could drink that” not that i would search for it and buy it but if someone gave me one Id hit it. Lol

Haven't been to conquest yet; which was the bad batch I should be ignoring? I have a few bottles of Cantillion Iris sitting in my aging attic that I look forward to cracking open one of these days; maybe I'll save it for a bottle share if I can ever make one.

TravelingLight

Well-Known Member

Just checked my untappd. It's called Stone Free. Avoid it like the plague. Or if you're feeling adventurous, get a taster and smell it.Haven't been to conquest yet; which was the bad batch I should be ignoring? I have a few bottles of Cantillion Iris sitting in my aging attic that I look forward to cracking open one of these days; maybe I'll save it for a bottle share if I can ever make one.

Well, to add to the conversation, got back from training and took gravity samples. The ~5.00 gallon batch attenuated slightly more to a current reading of 1.016 (10.50% abv; 80% aa); the ~2.5 gallon batch is sitting at 1.018 (10.24% abv; 80% AA); i think both were at 1.096 from the sugar addition I did before. Couldn't help but notice that the 10.50% batch had a whole lot more crap in the bottom (probably all the cold break from the z-chiller, and other crap). Both gravity samples are chilling for some "other" sampling. Dumped the bourbon barrel chips and some of the beam into the 10.50% sample. I'll be curious to see how it is at bottling and then again in the mid December timeframe. My over-attenuated helles (I think that's a good thing...) is now lagering for a while.

Maybe, there is a TON of material at the bottom of that one. That might have lead to slight overpitching vice the smaller batch, or I might have bumped the gravity up slightly differently with the sugar. Even green and uncarbed it tastes like a nice dry stout, so I can't complain either way. Think I'll start planning my quad out...

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

So im interested in making a carboy and keg washer. I know some of you have them. I already have some of the things to build it. So you can just make about 1-2 gallons of cleaning solution and spray it in the keg or carboy for 15 minutes and its clean?

Also does yours have keg connectors on it? To clean the inside of the posts? The build i saw had that and its a good idea but cant you just soak those easily in a small amount of pbw or is it better to add that to the keg washer?

Also does yours have keg connectors on it? To clean the inside of the posts? The build i saw had that and its a good idea but cant you just soak those easily in a small amount of pbw or is it better to add that to the keg washer?

Last edited:

TravelingLight

Well-Known Member

Yeah, I add about 2 gallons of hot water and PBW/oxyclean to the bucket and let it run for 20 mins or so. I'm usually cleaning multiple fermenters and/or kegs at the same time. So I usually cycle through all of them with cleaning solution. Then either spray them out with clean water, or empty the bucket and refill with clean cold water and cycle each vessel a few minutes.So im interested in making a carboy and keg washer. I know some of you have them. I already have some of the things to build it. So you can just make about 1-2 gallons of cleaning solution and spray it in the keg or carboy for 15 minutes and its clean?

Also does yours have keg connectors on it? To clean the inside of the posts? The build i saw had that and its a good idea but cant you just soak those easily in a small amount of pbw or is it better to add that to the keg washer?

Currently I don't have post cleaners on mine, but it's just because I haven't gotten off my ass to add them. So right now, if need be, I remove the posts and dip tubes and soak those separately while the keg is on the washer. But I'm going to add a piece of line to the base of my PVC sprayer with a BLQD on it to connect to the dip tube and clean that simultaneously. That, or I may just add a ball lock post to the PVC sprayer and use my jumper tubing with ball lock QDs on both ends.

https://www.morebeer.com/products/morebeer-ball-lock-corny-keg-rinser.html

I bought one of these, but haven't had to rinse out a keg yet. It has a garden hose attachment, so I imagine it could work with my normal cold-water sump pump and PBW recirculating through it. I will admit I'm not sure just how strong the hose is (and my 1/4 hp sump pump will do, like, 1020 gallons per hour with at least 10 feet of lift). I did upgrade to reinforce silicon hosing on my chillers for safety, but I guess i'll find out when it comes to cleaning time outside and away from my breakables.

I bought one of these, but haven't had to rinse out a keg yet. It has a garden hose attachment, so I imagine it could work with my normal cold-water sump pump and PBW recirculating through it. I will admit I'm not sure just how strong the hose is (and my 1/4 hp sump pump will do, like, 1020 gallons per hour with at least 10 feet of lift). I did upgrade to reinforce silicon hosing on my chillers for safety, but I guess i'll find out when it comes to cleaning time outside and away from my breakables.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

So i brewed a session ipa tonight and i had this idea after last brew session. I thought it was a good one. Turns out it wasnt. I brewed it all as normal but when i added my chiller. I also added my hop spider. I kept the hops outside the stainless spider. And i siphoned from inside the spider. Seems like it would work right? Wrong. The spider clogged and it dried up with a few gallons left in the kettle. Just thought id share my experiment with you guys in case anyone got the same idea lol

Recipe thoughts time!

Name: Unnamed Christmas Beer (Possibly some pun about lawyer's tears being highly alcoholic)

Water/Stats

--------------------------

12.50 gallons set to Brugges (2.5 q/lb)

Target OG: 1.093 @ 7.7 gallons (assuming 80% efficiency; 7.25 gallons @ 75%, 6.9 @ 70%)

Target FG: 1.012

Target ABV: 10.63%

Yeast:

--------------------------

WLP 530 (Westmalle)

Grain Bill:

--------------------------

10 Pounds Pale 2 Row

10 Pounds Belgian Pilsner

3.75 120l sugar (2/3 added during boil, remainder added at terminal temperature)

Hops: (Note: amount not scalled; to 35 ibu; I tend to calculate this during the mash)

--------------------------

1.0 oz - Northern Brewer - 90 min

1.0 oz - Styrian Goldings - 20 min

0.5 oz - Hallertauer - 20 minutes

Magnum hops as needed

Mash Schedule:

--------------------------

00 - 45 min: Dough-in @ 135, immediate ramp to 145

45 - 75 min: ramp to 165; iodophor test @ 75 min

75: mashout @ 172 for 10 min

90 minute boil

Ferment Schedule

--------------------------

Pitch @ 64, increase by 3* per day until 82/FG achieved

Gelatin Fine and cold crash @ 30 for 2 days

Bottle condition for 2 weeks to carbonate

Lager for 4+ weeks

Warm condition until Christmas Market time

Notes:

--------------------------

Mash schedule allegedly from Rochefort per Brew Like a Monk; slightly different than my usual hockhurz mash, which historically has produced a very fermentable wort (as evided by my helles and stout; previous belgian had over 85% with WLP 570)

Temperature measured via thermowell of largest fermenter; the small one will just have to suck it up.

I'll be breaking in my new speidel fermenters (after my better bottle/fermonster warped/partially melted)

My math says this will fill a 2.5 gallon keg and just shy of three cases of 12 oz bottles.

Name: Unnamed Christmas Beer (Possibly some pun about lawyer's tears being highly alcoholic)

Water/Stats

--------------------------

12.50 gallons set to Brugges (2.5 q/lb)

Target OG: 1.093 @ 7.7 gallons (assuming 80% efficiency; 7.25 gallons @ 75%, 6.9 @ 70%)

Target FG: 1.012

Target ABV: 10.63%

Yeast:

--------------------------

WLP 530 (Westmalle)

Grain Bill:

--------------------------

10 Pounds Pale 2 Row

10 Pounds Belgian Pilsner

3.75 120l sugar (2/3 added during boil, remainder added at terminal temperature)

Hops: (Note: amount not scalled; to 35 ibu; I tend to calculate this during the mash)

--------------------------

1.0 oz - Northern Brewer - 90 min

1.0 oz - Styrian Goldings - 20 min

0.5 oz - Hallertauer - 20 minutes

Magnum hops as needed

Mash Schedule:

--------------------------

00 - 45 min: Dough-in @ 135, immediate ramp to 145

45 - 75 min: ramp to 165; iodophor test @ 75 min

75: mashout @ 172 for 10 min

90 minute boil

Ferment Schedule

--------------------------

Pitch @ 64, increase by 3* per day until 82/FG achieved

Gelatin Fine and cold crash @ 30 for 2 days

Bottle condition for 2 weeks to carbonate

Lager for 4+ weeks

Warm condition until Christmas Market time

Notes:

--------------------------

Mash schedule allegedly from Rochefort per Brew Like a Monk; slightly different than my usual hockhurz mash, which historically has produced a very fermentable wort (as evided by my helles and stout; previous belgian had over 85% with WLP 570)

Temperature measured via thermowell of largest fermenter; the small one will just have to suck it up.

I'll be breaking in my new speidel fermenters (after my better bottle/fermonster warped/partially melted)

My math says this will fill a 2.5 gallon keg and just shy of three cases of 12 oz bottles.

TravelingLight

Well-Known Member

Starting a new job tomorrow (same agency, different area). Feels so weird packing up my office. I haven't had a new job in years. It's bittersweet.

catdaddy66

Well-Known Member

A new challenge, my friend! Good luck, you'll crush it.

SHAIV

Well-Known Member

- Joined

- Sep 8, 2015

- Messages

- 615

- Reaction score

- 160

Starting a new job tomorrow (same agency, different area). Feels so weird packing up my office. I haven't had a new job in years. It's bittersweet.

Nice! So does that mean more or less brewing?

TravelingLight

Well-Known Member

Haha, asking the real questions! I doubt it'll change my brewing at all. Except for the fact that I got a nice raise with this, and I will be treating myself to some new toys (pump, cam locks, etc etc). Although, I will definitely be busier Jan-June when the legislature is in session. So we shall see if my brewing habits change in the spring...Nice! So does that mean more or less brewing?

If you want to give any of my crap a whirl before you buy, you're more than welcome to. I'll admit, I'd almost want to go with Spike's QD's over cam locks; I occasionally have problems getting the cams to seal, especially when the hoses are hot.

TravelingLight

Well-Known Member

Thanks dude, might take you up on that. I collab'd with @Morrey this weekend on a brut IPA. Now I want a new kettle too. And fermenters. His chronicals and uni tank are #goals.If you want to give any of my crap a whirl before you buy, you're more than welcome to. I'll admit, I'd almost want to go with Spike's QD's over cam locks; I occasionally have problems getting the cams to seal, especially when the hoses are hot.

I want a new kettle also. And a HLT. And a conical fermenter. And a nice brew stand to put them on. And a brew shed to house all of them. The brew shed is coming. I have the money saved and put aside. A friend is going to be helping me build it. He is putting together a materials list for me.

I brewed my first lager last night (mexican lager) and will be brewing my second tonight(Oktoberfest). This way I can ferment them with the same schedule and have them ready around the same time.

I brewed my first lager last night (mexican lager) and will be brewing my second tonight(Oktoberfest). This way I can ferment them with the same schedule and have them ready around the same time.

Similar threads

- Replies

- 3

- Views

- 728

South Carolina

Pee Dee Brewers (Florence, Hartsville, etc.)

- Replies

- 1

- Views

- 656

- Replies

- 134

- Views

- 4K