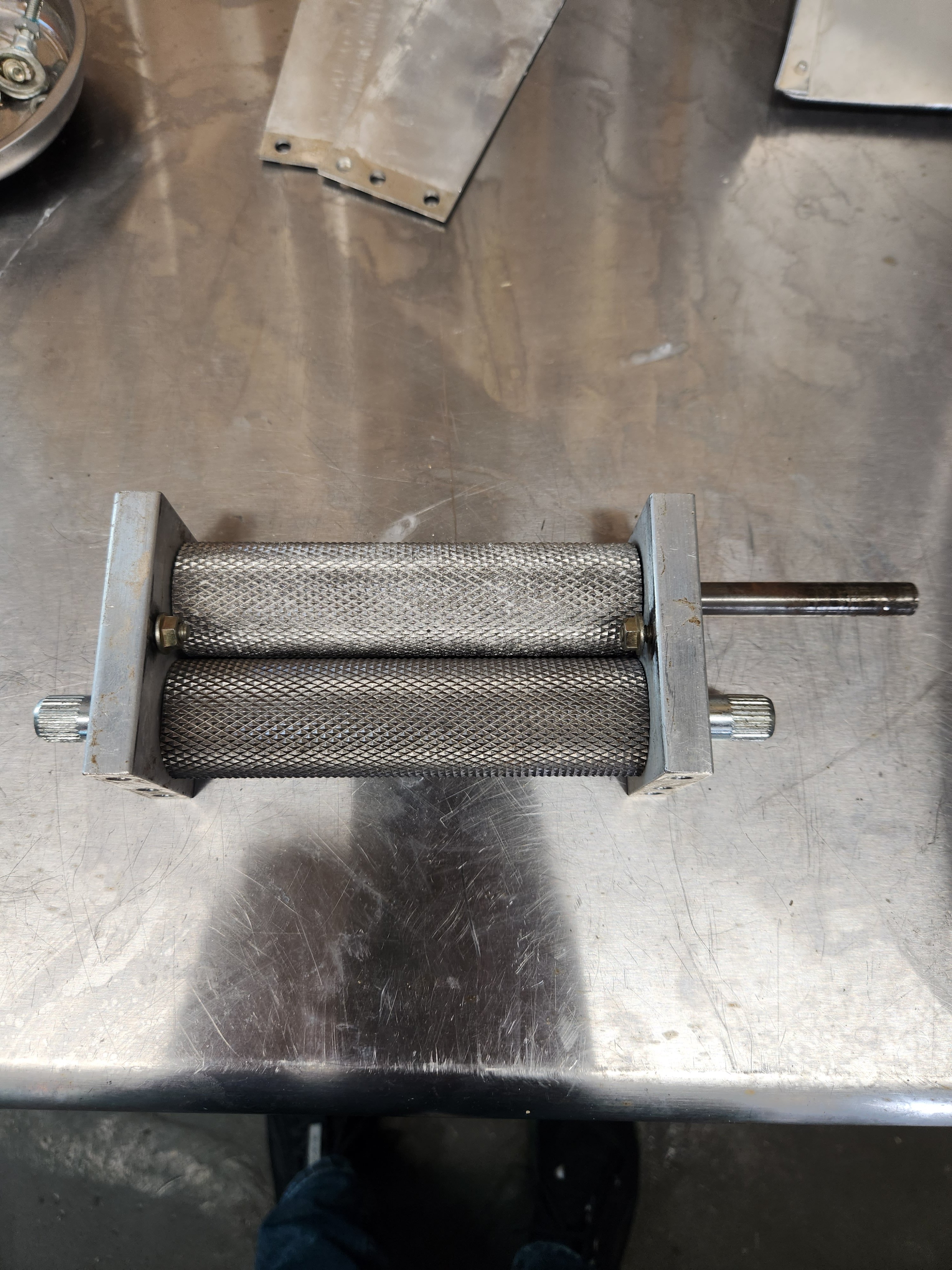

I noticed that my rollers weren't rolling properly and after disassembling the mill, the four bearing sets were just barely functioning. Fortunately the part numbers were still visible so after some searching I found good looking replacements. I did make one change though. The originals were single shielded bearings and I swapped them out for double sealed bearings. There is a lower RPM tolerance for sealed but since the mill runs at such a low RPM anyway I decided I didn't care.

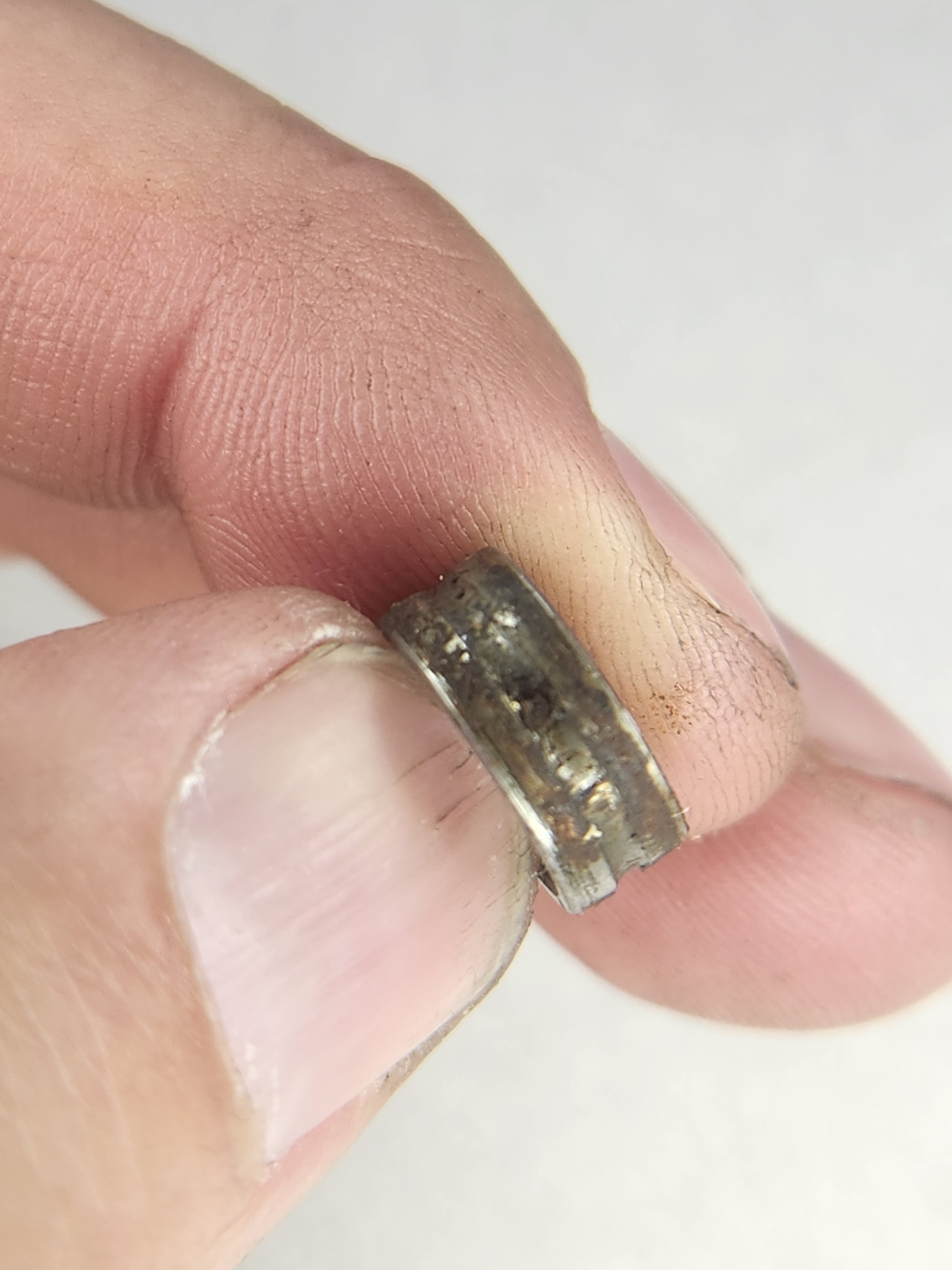

You can see significant damage from the roller contact with the soft aluminum block. Getting the bearings out of the blocks were simple, I just inserted a brass drift into the rear of the block and tapped them out. The rollers were another issue. We ended up rigging a puller out of a vice and a couple nails and with a slide hammer got them out.

Pressing the new ones in was painless.

Hopefully this fixes my problems I was having.

You can see significant damage from the roller contact with the soft aluminum block. Getting the bearings out of the blocks were simple, I just inserted a brass drift into the rear of the block and tapped them out. The rollers were another issue. We ended up rigging a puller out of a vice and a couple nails and with a slide hammer got them out.

Pressing the new ones in was painless.

Hopefully this fixes my problems I was having.