TeamAshBrewing

Well-Known Member

Hello,

I am getting different predicted Mash pH amounts using Brunwater, EZWater, and Mash Made Easy. I am wondering if I am entering data incorrect or something else. To get to a 5.4pH using Lactic Acid, Brunwater recommends adding 1.5mL to the mash water + .4mL sparge water.

Both EZWater (3.5mL) and Mash Made Easy (3.38mL) recommend twice the amounts to the mash water alone. The mash water profile is off too, but not a lot.

I will be brewing a German Pilsner using the following data:

5.5gal Total Batch Volume

100% RO Water

3.75gal Mash Water

5.77gal Sparge Water

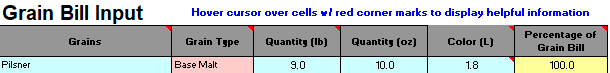

9.625 lbs Pilsner Malt 1.7L (Weyerman)

Target Water Profile

59 calcium

8 mg

89 sulfate

63 chloride

Salt Additions Mash + Sparge = Total

Gypsum .75 + 1.2= 1.95gr

CaCl2 1.31 + 2.0 = 3.31gr

Epsom 1.13 + 1.7 = 2.83gr

Thanks for the help.

Chris

I am getting different predicted Mash pH amounts using Brunwater, EZWater, and Mash Made Easy. I am wondering if I am entering data incorrect or something else. To get to a 5.4pH using Lactic Acid, Brunwater recommends adding 1.5mL to the mash water + .4mL sparge water.

Both EZWater (3.5mL) and Mash Made Easy (3.38mL) recommend twice the amounts to the mash water alone. The mash water profile is off too, but not a lot.

I will be brewing a German Pilsner using the following data:

5.5gal Total Batch Volume

100% RO Water

3.75gal Mash Water

5.77gal Sparge Water

9.625 lbs Pilsner Malt 1.7L (Weyerman)

Target Water Profile

59 calcium

8 mg

89 sulfate

63 chloride

Salt Additions Mash + Sparge = Total

Gypsum .75 + 1.2= 1.95gr

CaCl2 1.31 + 2.0 = 3.31gr

Epsom 1.13 + 1.7 = 2.83gr

Thanks for the help.

Chris