Hi everyone,

This is my first time posting a DIY project. I've gotten so much information from HBT and the posts here; I don't know if I would be able to homebrew successfully with it.

Anyway, I'd like to share my portable keg cooler. I originally built the garbage can model but decided it was too heavy to be practical for me. If you entertain a lot, go to a bunch of parties, and/or have a vehicle large enough to haul it then that's great. I don't, so I built this. Others have done the same project or similar projects, but I wanted to share. Enjoy!

Parts

--------------------

Igloo Cooler from Sam's Club 60qt

Great Stuff spray foam

Faucet with QD attached

20oz Paintball Tank

Harbor Freight CO2 regulator

Vinyl Air hose tubing from Harbor Freight (cheap!...a little big but I cranked on the worm clamps and it worked great)

3M "Sea Blue" Duct tape (found it at Lowes)

The first pics show the lid removed from the cooler. I used a flathead scredriver to pop it off. Pretty easy

Then I took my Dremel tool and sanded off the white plastic "hinge pin" on the body of the cooler itself. Due to the angles you have to assembly the set up straight down (no angle)

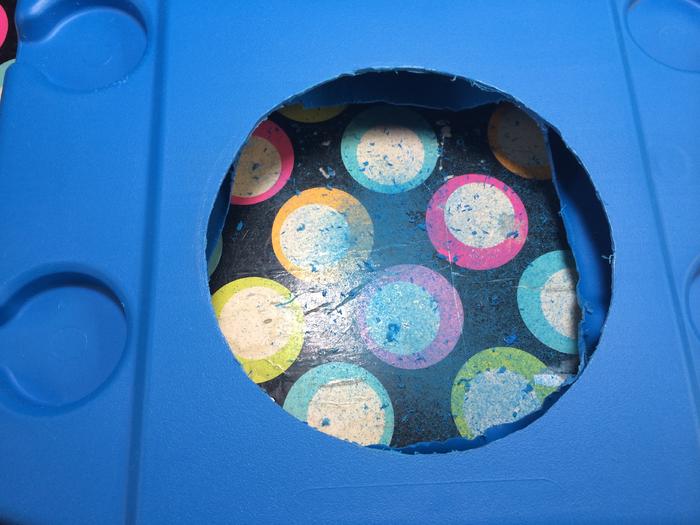

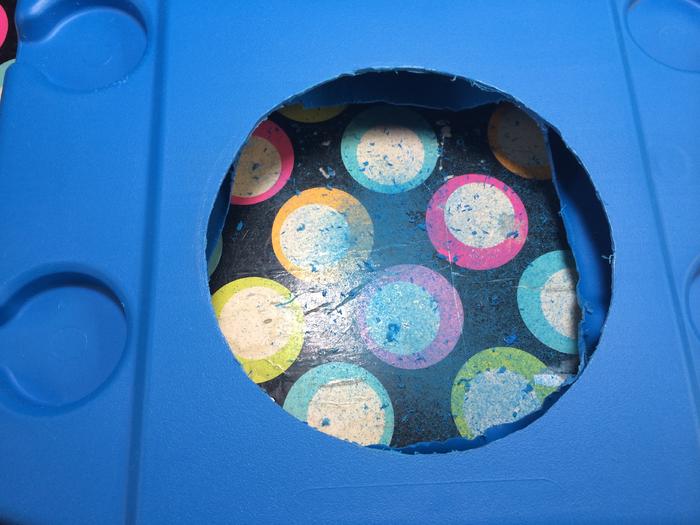

I measured my keg (Firestone Challenger ball lock) and added some space, then drew a circle with a compass. I would be more generous here, as it is now a pretty tight fit.

Next I cut the hole using a Rotozip bit for my Dremel. I got close to the line then finished up with the sanding wheel. Did a nice job actually, I was impressed.

One thing you can't see is that most cooler lids are hollow. I filled it with Great Stuff to extend past diameter of the whole, then trimmed it once it hardened. I used 3M Blue Duct Tape to seal around the edges. I overlapped and made it sloppy then used my compass again to trace a neat circle and trimmed with a sharp razor blade. Came out pretty well, although I think I'll be adding more of a "flange" of tape as the pressure of removing and re-installing the keg moves the tap around more than I'd like.

This is my first time posting a DIY project. I've gotten so much information from HBT and the posts here; I don't know if I would be able to homebrew successfully with it.

Anyway, I'd like to share my portable keg cooler. I originally built the garbage can model but decided it was too heavy to be practical for me. If you entertain a lot, go to a bunch of parties, and/or have a vehicle large enough to haul it then that's great. I don't, so I built this. Others have done the same project or similar projects, but I wanted to share. Enjoy!

Parts

--------------------

Igloo Cooler from Sam's Club 60qt

Great Stuff spray foam

Faucet with QD attached

20oz Paintball Tank

Harbor Freight CO2 regulator

Vinyl Air hose tubing from Harbor Freight (cheap!...a little big but I cranked on the worm clamps and it worked great)

3M "Sea Blue" Duct tape (found it at Lowes)

The first pics show the lid removed from the cooler. I used a flathead scredriver to pop it off. Pretty easy

Then I took my Dremel tool and sanded off the white plastic "hinge pin" on the body of the cooler itself. Due to the angles you have to assembly the set up straight down (no angle)

I measured my keg (Firestone Challenger ball lock) and added some space, then drew a circle with a compass. I would be more generous here, as it is now a pretty tight fit.

Next I cut the hole using a Rotozip bit for my Dremel. I got close to the line then finished up with the sanding wheel. Did a nice job actually, I was impressed.

One thing you can't see is that most cooler lids are hollow. I filled it with Great Stuff to extend past diameter of the whole, then trimmed it once it hardened. I used 3M Blue Duct Tape to seal around the edges. I overlapped and made it sloppy then used my compass again to trace a neat circle and trimmed with a sharp razor blade. Came out pretty well, although I think I'll be adding more of a "flange" of tape as the pressure of removing and re-installing the keg moves the tap around more than I'd like.