kpr121

Well-Known Member

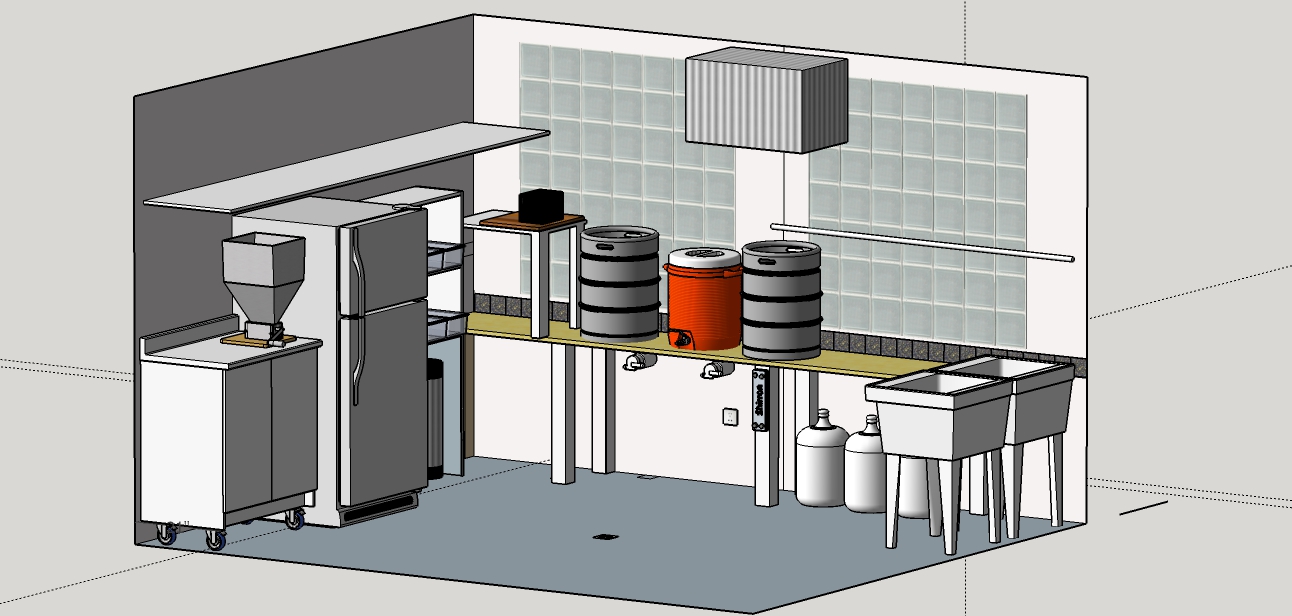

Hey all, Im going to be closing on a new house at the end of Sept and one of the first priorities (for me, maybe not so much SWMBO) is setting up the brewery. So I've been messing around with Google Sketchup trying to come up with a good layout. Would appreciate any input and ideas, I am kind of setting this up with the same layout I had before because it feels more comfortable, but figured if there was ever a good time to makes some tweaks now would be the time.

A couple points:

This is an all electric, 220, 5500 w elements in HLT and BK setup. Existing room has dryer hookup on wall that brewstand is shown. Black box in pictures is my control panel.

Sink is fairly set in place. It is already there, and is cast iron.

Wall that brewstand is shown on is on exterior wall.

There is a floor drain in center of room, not sure if I'll be able to use this or not but would love to. Floor is concrete.

A couple points:

This is an all electric, 220, 5500 w elements in HLT and BK setup. Existing room has dryer hookup on wall that brewstand is shown. Black box in pictures is my control panel.

Sink is fairly set in place. It is already there, and is cast iron.

Wall that brewstand is shown on is on exterior wall.

There is a floor drain in center of room, not sure if I'll be able to use this or not but would love to. Floor is concrete.