rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 774

- Reaction score

- 174

I haven't used my new eBIAB system yet. First time.

I'm planning on making the Cream of Three Crops Cream Ale.

My tap water sucks for all-grain brewing so I need to use RO water and add minerals.

My kettle is wider than it is tall and I think I'll have to do a 10-gal batch the first time to see how it goes. Maybe in the future I can make less, but I'll have to gauge that. For now, I'm wanting to end up with 10 gallons bottled (yes, bottled - not enough $$ for kegging yet).

The brew system:

25 gallon aluminum kettle 17.5" tall x 20.5" wide

5500w heat element run by a homemade Craftbeerpi controller

Homemade false bottom to keep the BIAB off the element

Full-volume mashing. No sparging. Pump and Craftbeerpi to keep mash temp stable.

Losses (I'm guessing a bit here, but I think it's close):

I figure my kettle loss is only about 1 pint, maybe a little more.

I'm using a boil steam condenser, so I think my boil-off rate is about .6gal/hr (lid on during boil)

I have a Counter-flow chiller of about 19' of 1/2" copper pipe. So that's about 1 qt.

I don't know about trub loss.

The above comes to about 1.3 gallons of loss total.

Ingredients:

12-lb Pale Malt

4-lb flaked corn

1-lb minute rice

I have a Ugly Corona Mill so I should be able to grind pretty fine. I'll be my first time using it.

90 min mash at 152F (according to the recipe)

90 minute boil

1oz Willamette hops at 60min

1oz of Crystal hops at 60 minutes

Split the wort into 2 fermenters and use Kosch yeast for one, Nottingham for the other.

I have a homemade JaDeD Cyclone-type CFC to chill the wort before putting in 2 separate fermenting buckets and/or carboys and plan on using Kolsch yeast in one and Nottingham in the other.

For mashing, I'll need 13.2 gallons according to the Priceless calculator, correct? But Beersmith says I need 15.04 gallons. I guess I have different equipment setups for each calculation then. I've never used either one before.

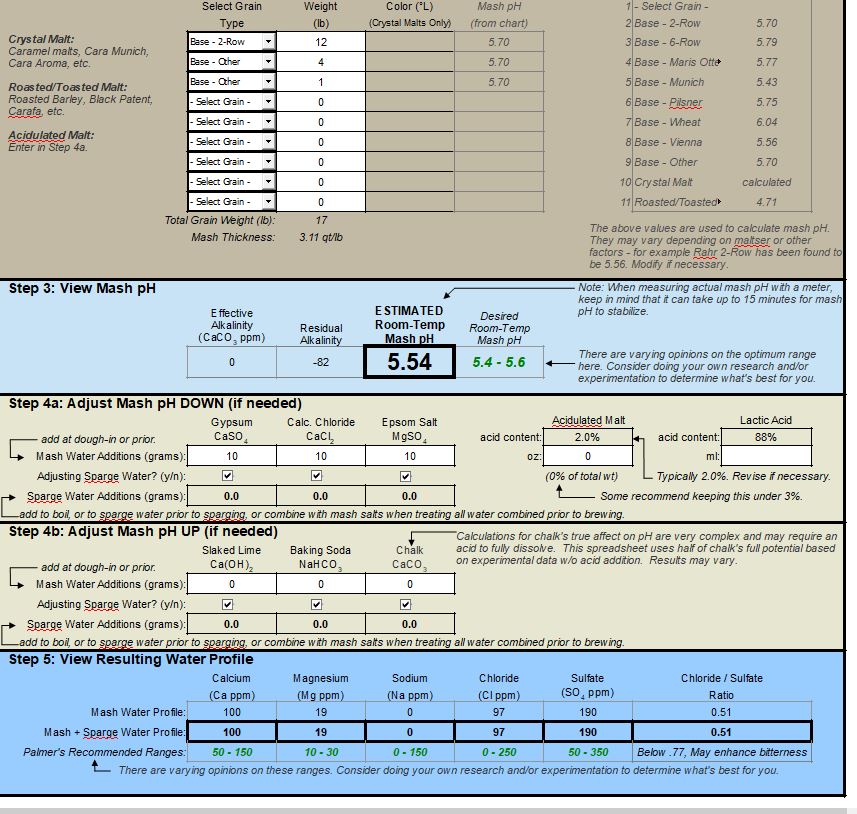

Since I'm starting with RO water, I used EZ Water Calculator to see what I need to add. If I use 13.2 gallons of water as a starting point (but, see just above):

Add:

10 grams of Gypsum

10 grams of Calcium Chloride

10 grams of Epsom Salt

To get 5.54 est. mash pH.

But the Chloride / Sulfate ratio is 0.51. Should that ratio be higher?

I have no clue if those numbers of water additions are proper to use.

Are my numbers correct? Am I missing anything? I'm new to all this calculating....I've only done extracts before.

Thanks for listening.

I'm planning on making the Cream of Three Crops Cream Ale.

My tap water sucks for all-grain brewing so I need to use RO water and add minerals.

My kettle is wider than it is tall and I think I'll have to do a 10-gal batch the first time to see how it goes. Maybe in the future I can make less, but I'll have to gauge that. For now, I'm wanting to end up with 10 gallons bottled (yes, bottled - not enough $$ for kegging yet).

The brew system:

25 gallon aluminum kettle 17.5" tall x 20.5" wide

5500w heat element run by a homemade Craftbeerpi controller

Homemade false bottom to keep the BIAB off the element

Full-volume mashing. No sparging. Pump and Craftbeerpi to keep mash temp stable.

Losses (I'm guessing a bit here, but I think it's close):

I figure my kettle loss is only about 1 pint, maybe a little more.

I'm using a boil steam condenser, so I think my boil-off rate is about .6gal/hr (lid on during boil)

I have a Counter-flow chiller of about 19' of 1/2" copper pipe. So that's about 1 qt.

I don't know about trub loss.

The above comes to about 1.3 gallons of loss total.

Ingredients:

12-lb Pale Malt

4-lb flaked corn

1-lb minute rice

I have a Ugly Corona Mill so I should be able to grind pretty fine. I'll be my first time using it.

90 min mash at 152F (according to the recipe)

90 minute boil

1oz Willamette hops at 60min

1oz of Crystal hops at 60 minutes

Split the wort into 2 fermenters and use Kosch yeast for one, Nottingham for the other.

I have a homemade JaDeD Cyclone-type CFC to chill the wort before putting in 2 separate fermenting buckets and/or carboys and plan on using Kolsch yeast in one and Nottingham in the other.

For mashing, I'll need 13.2 gallons according to the Priceless calculator, correct? But Beersmith says I need 15.04 gallons. I guess I have different equipment setups for each calculation then. I've never used either one before.

Since I'm starting with RO water, I used EZ Water Calculator to see what I need to add. If I use 13.2 gallons of water as a starting point (but, see just above):

Add:

10 grams of Gypsum

10 grams of Calcium Chloride

10 grams of Epsom Salt

To get 5.54 est. mash pH.

But the Chloride / Sulfate ratio is 0.51. Should that ratio be higher?

I have no clue if those numbers of water additions are proper to use.

Are my numbers correct? Am I missing anything? I'm new to all this calculating....I've only done extracts before.

Thanks for listening.