dantzerman

Active Member

- Joined

- Jun 27, 2012

- Messages

- 30

- Reaction score

- 3

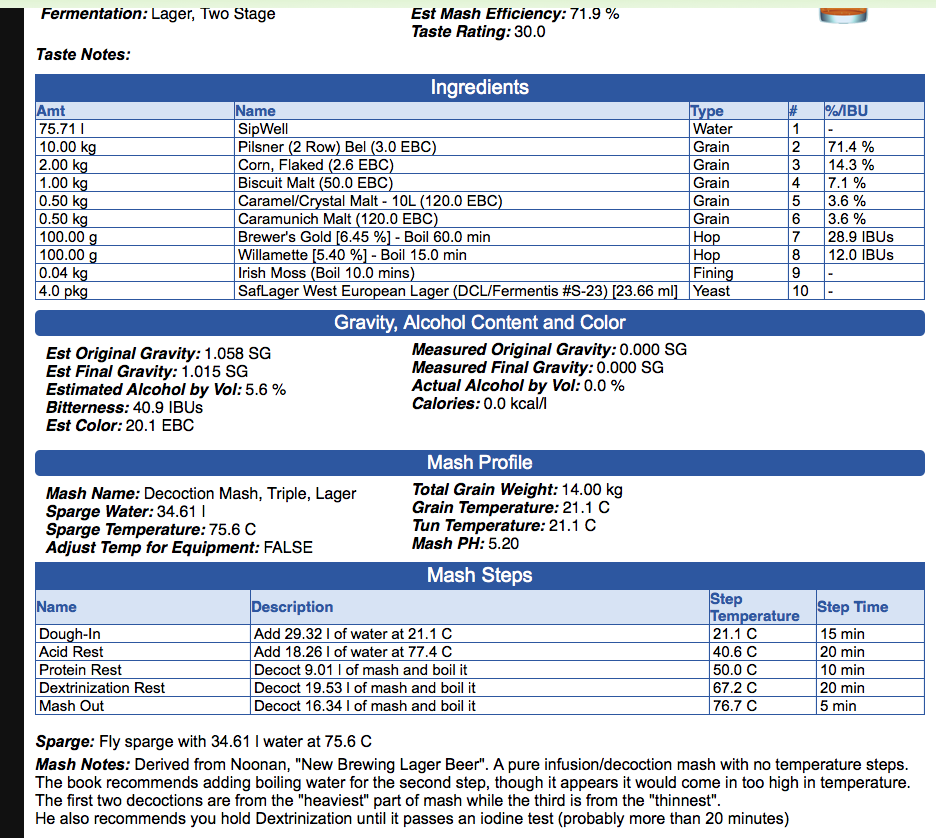

Hi, I am getting ready to make my version of a Bohemian Pilsner and enter it in a contest. I plan to make a 10-13 gal batch and I have a 26 gal cooking kettle. I used Beer Smith software to scale my recipe and help with water volumes. I wanted to try a process modification and was wondering if there are any reasons against it. This will be my largest batch ever.

Specifically, during boiling I wanted to boil for the standard 90 min, add the bittering hops after 15 min and the aroma hops after 60 min, removing all hops after 75 min and then add irish moss to boil for 15 min. The reason is that I was thinking the irish moss may get tied up in the hops bags. I was going to add 10 percent extra hops to my recipe to compensate for the last 15 min of boil without hops. I also like using hop cones that swell alot rather than the pellets.

Thank you for you comments and please drink a beer for me.

Specifically, during boiling I wanted to boil for the standard 90 min, add the bittering hops after 15 min and the aroma hops after 60 min, removing all hops after 75 min and then add irish moss to boil for 15 min. The reason is that I was thinking the irish moss may get tied up in the hops bags. I was going to add 10 percent extra hops to my recipe to compensate for the last 15 min of boil without hops. I also like using hop cones that swell alot rather than the pellets.

Thank you for you comments and please drink a beer for me.