The power output to the element does drop off in proportion to the SP and by the time the SP is reached the element should be the same temp as the solution the temp probe is sensing. That is what true proportional control is.

In true proportional control one part of the output is proportional to the difference between the SP and the PV. When the PV reaches the SP then there is 0 output. If the thermal masses of heater and load were both infinitessimal so that their thermal time constants were effectively 0 and there were no losses to the environment then a proportional controller would go straight to the set point and stay there. But that's not the real world. To deal with the simplest of these concepts if there is heat loss the element must be partially on i.e. supplying heat to the load in order to make up for those losses. Under these conditions a P only controller cannot hold the set point. It has to take the load to a temperature somewhat below the set point so that there is a finite difference between SP and PV in order that there be output to maintain a heat flow into the load. A P only system is a 0th order loop. It can follow change in setpoint but it cannot reach setpoint.

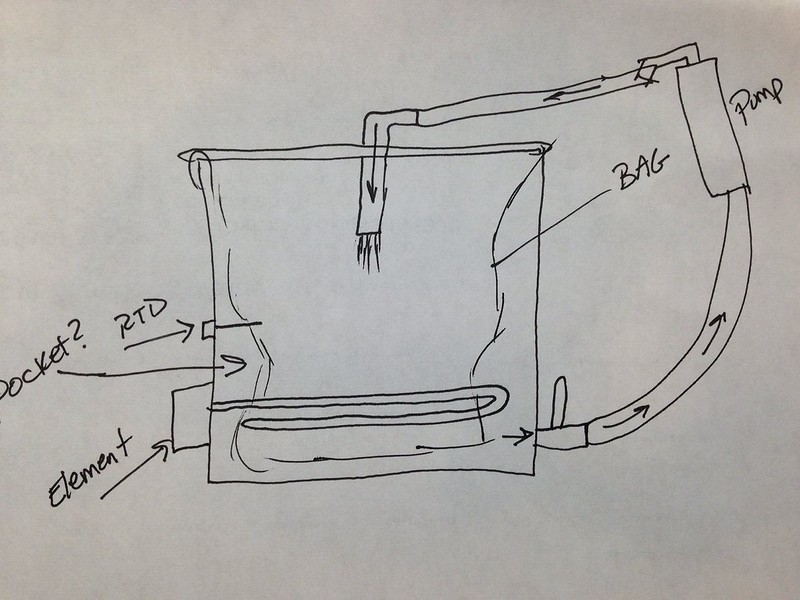

So now suppose that the error (SP - PV) controls a pump which pumps water into a can. And lets suppose the weight of that can of water controls the power output to the heater. The heavier the can the more heat. When we turn the system on (there is no P component to this system) the can is empty and there is no heat applied but this results in a large flow of water because SP - PV is large so the can starts to fill quickly and heat starts to be applied to the load. This results in its temperature rising so that SP - PV becomes smaller and the rate of flow of water into the can decreases but it keeps getting heavier and so more heat is applied which causes the temperature of the load to rise further. At some point PV = SP and the pump goes off but there is still water in the can and thus still heat being applied to the load. This heat balances the heat lost so that the system holds at PV = SP.

In the real world there is a time lag between when heat is applied and when the temperature rises and there is also a time lag between when the temperature reaches a certain value and the device measuring it senses that. Thus PV does not represent the true state of the system to include recent heat inputs. This is the reason for overshoot and droop. It also explains, in part why the response of a system like this (an integral system) is slow. The other part is that the error signal has to 'integrate up'

So a Proportional system never reaches SP and an Integral system is slow responding and overshoots. Neither by itself will satisfactorily solve the control problem and so that is why they are combined in a PI system.

We can compensate for overshoot to some extent by observing that (PV-SP) does not change over time and adding extra heat in proportion to the rate of change of (PV-SP) with time. If the system is drooping then extra heat is added. This is the I channel in a PID system.

There should be no overshooting (on any detectable level that is).

A perfectly tuned system should be just that, perfect.

What is a perfectly tuned system? To my way of thinking it is one response to a unit step in SP would be a unit step in temperature. There is no such system. In coming up with a tuneset we must make compromises. If we want quick response we will have to accept overshoot and droop. If we allow no overshoot we have to accept an overdamped system which takes a long time to come to SP.

I setup and program PID position control systems and they have to be perfect,

Were there such a thing the world would be beating a path to your door.

no overshooting or oscillating.

This is, then, how you have done your tradeoff. To completely damp overshoot you must accept slower response.

If these systems were unstable, I would probably be out of a job.

Then you better tune them so they don't overshoot. Stability is a different issue. When I say that overshoot and droop are part of the world of PID I am assuming that the systems are properly tuned such that overshoot and droop damp out eventually.

Tuning a PID controller used to be an art. Now you just push the autotune button. The resulting tuneset is not perfect nor is it necessarily the best tuneset for the given application. It represents the algorithm designers compromise. For a given application it is often advisable to tweak the autotune parameters in order to best fit the application.

Brewing is a tough application for PID controllers because and input heat pulse may take a fraction of a minute to propagate throughout the mash and it is hard to mix mash uniformly enough that a sensor at one particular point accurately reflects the temperature of the whole mash.

Even our hydraulic system heaters which operate only on a differential based thermostat maintains the set point, give or take a degree or two.

I'm not sure I understand the relevance of this point to the current discussion. The differential in a differential controller is not the same as the differential in a PID controller.