Mountainsax

Well-Known Member

I know, I know, we need another build thread like we need more macro breweries! Hopefully I'll be able to come up with some useful tidbits that others can use. But if not, at least we all like pictures!

So here's the story, the Christmas bonus came, SWMBO is awesome, and the build begins!

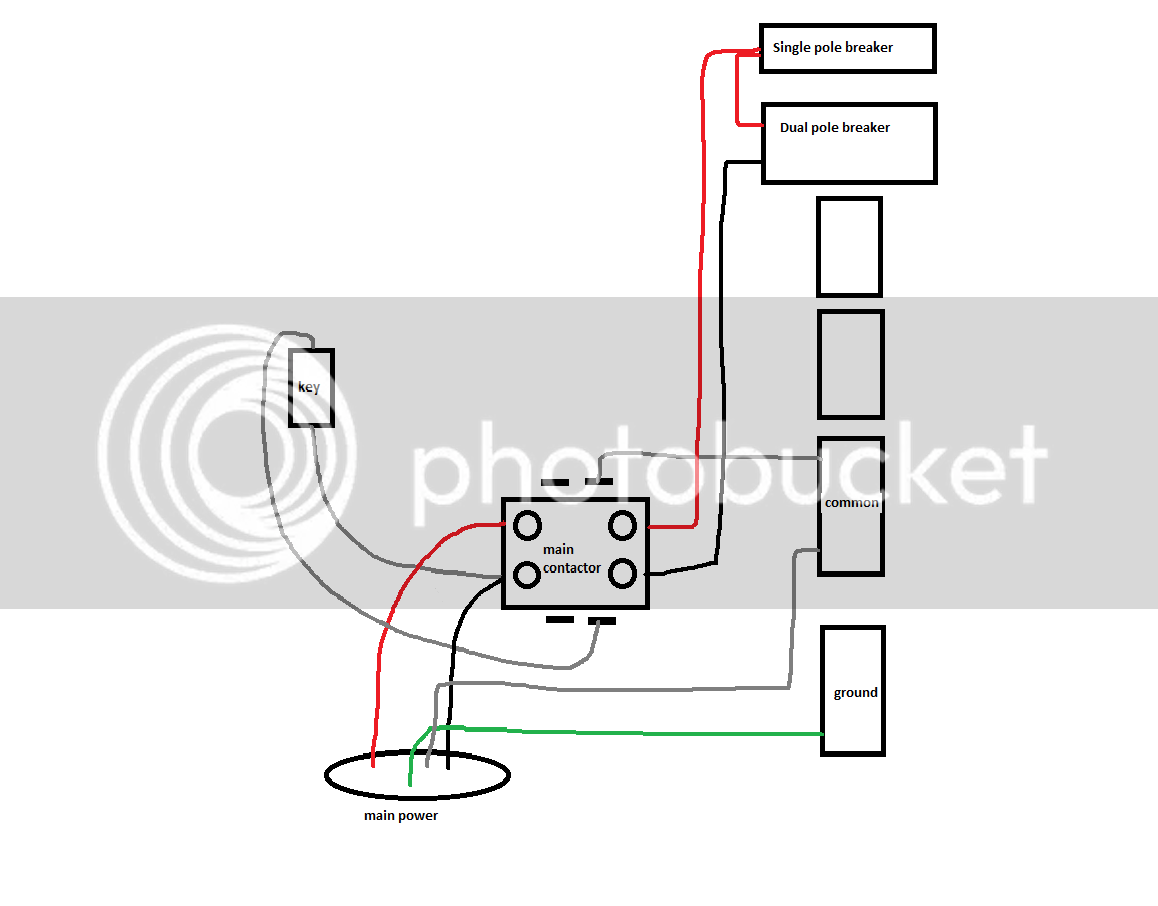

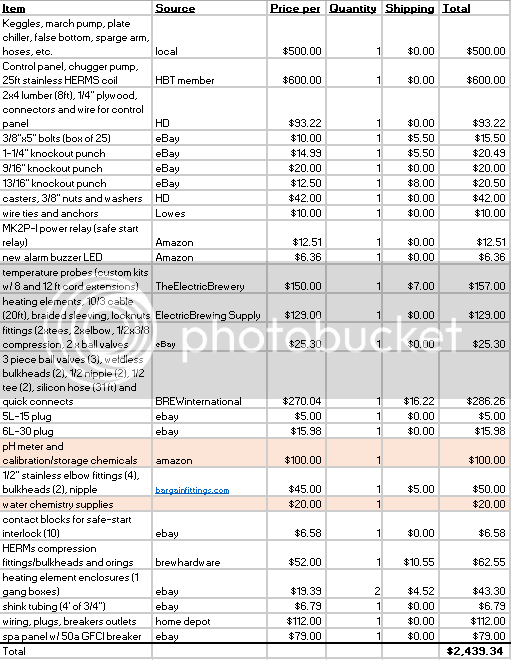

I'm planning a system based on Kal's design using keggles.

View attachment ImageUploadedByHome Brew1449061943.225124.jpg

The progress so far. The stand is pretty budget right now. Eventually I want to weld one out of stainless!

View attachment ImageUploadedByHome Brew1449062023.090796.jpg

The whole thing slides under my existing work bench. It does have wheels on it now.

So here's the story, the Christmas bonus came, SWMBO is awesome, and the build begins!

I'm planning a system based on Kal's design using keggles.

View attachment ImageUploadedByHome Brew1449061943.225124.jpg

The progress so far. The stand is pretty budget right now. Eventually I want to weld one out of stainless!

View attachment ImageUploadedByHome Brew1449062023.090796.jpg

The whole thing slides under my existing work bench. It does have wheels on it now.