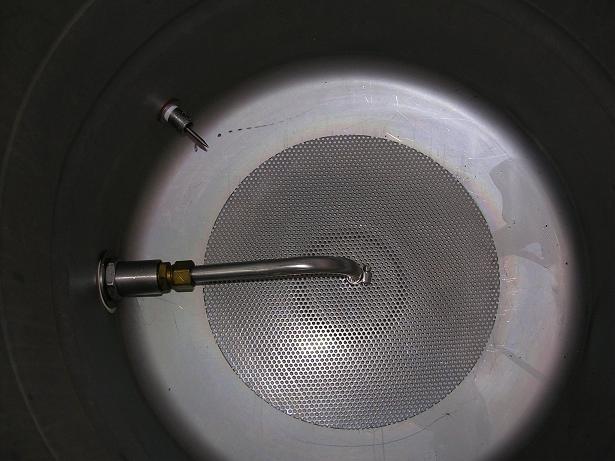

I need a false bottom for one of my sanke kegs that I am using as an MLT. The opening is 11-1/2", but I think I could get enough bow in a 12" to slip in without hinges. I am having trouble deciding on a size though.

It would seem that the largest that will fit will provide a greater surface area and therefore be better for lautering. But I see a lot of the ones listed for the sanke as being 9" - 10" or so.

What size seems to work the best?

It would seem that the largest that will fit will provide a greater surface area and therefore be better for lautering. But I see a lot of the ones listed for the sanke as being 9" - 10" or so.

What size seems to work the best?