rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 774

- Reaction score

- 174

Hello,

I bought a used kegerator. I switched the control of it over to a CraftbeerPi controller.

I'm wondering about two things before I keg for the first time:

1. Tower temp - how high is too high?

2. Cycle time of the compressor

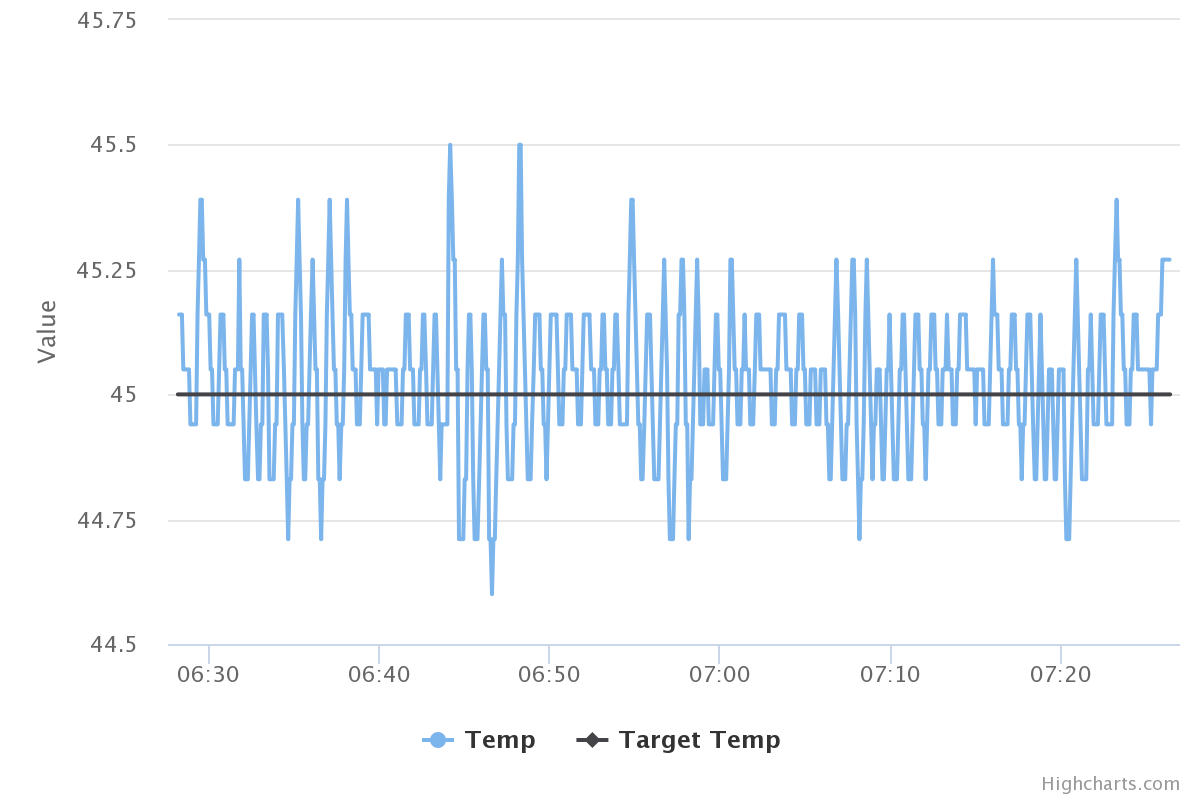

I put a fan blowing up through a tube into the tower. The temps are cooler, but I'm wondering if still too warm and I'll end up with foamy beer the first pour.

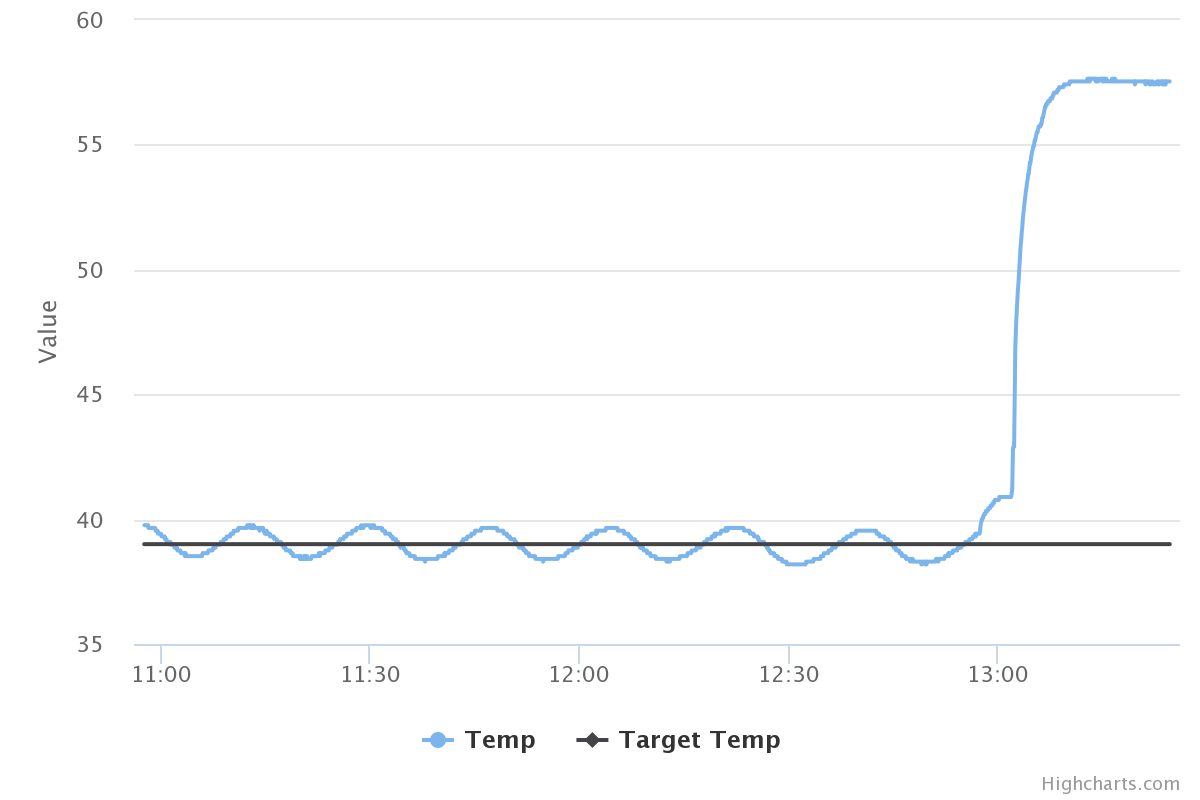

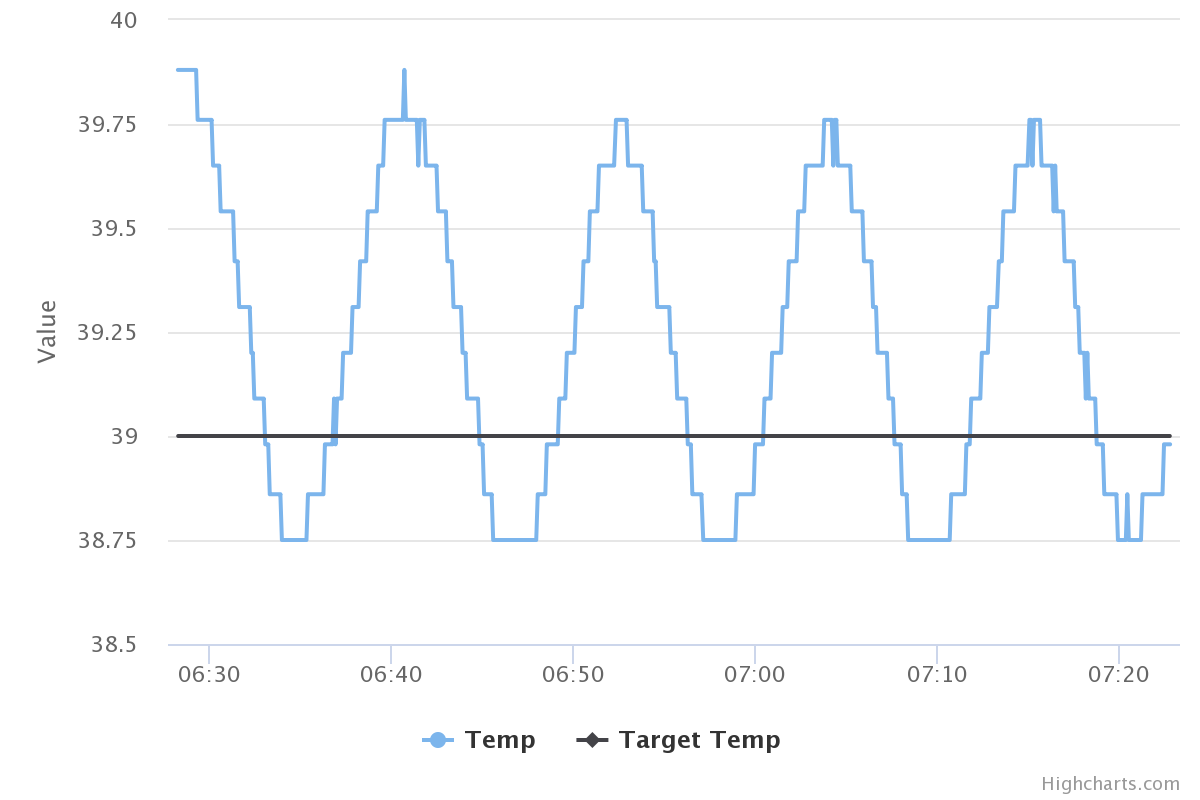

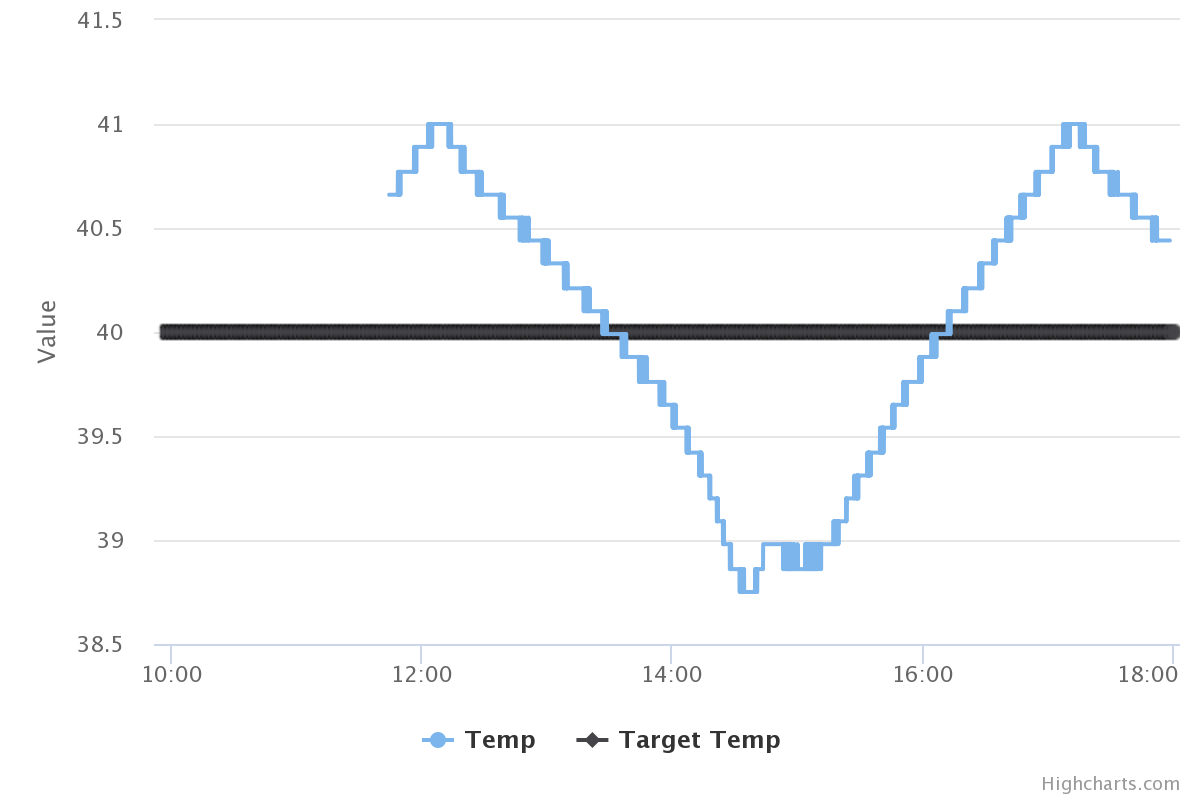

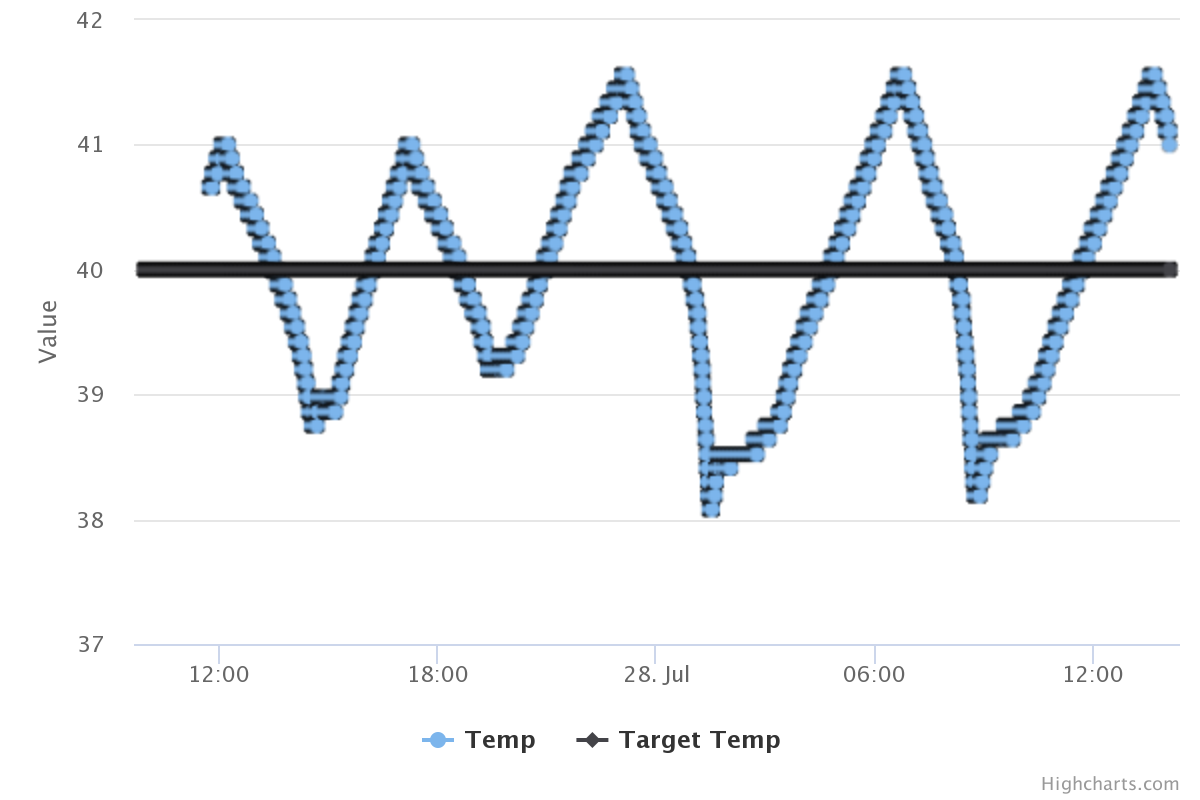

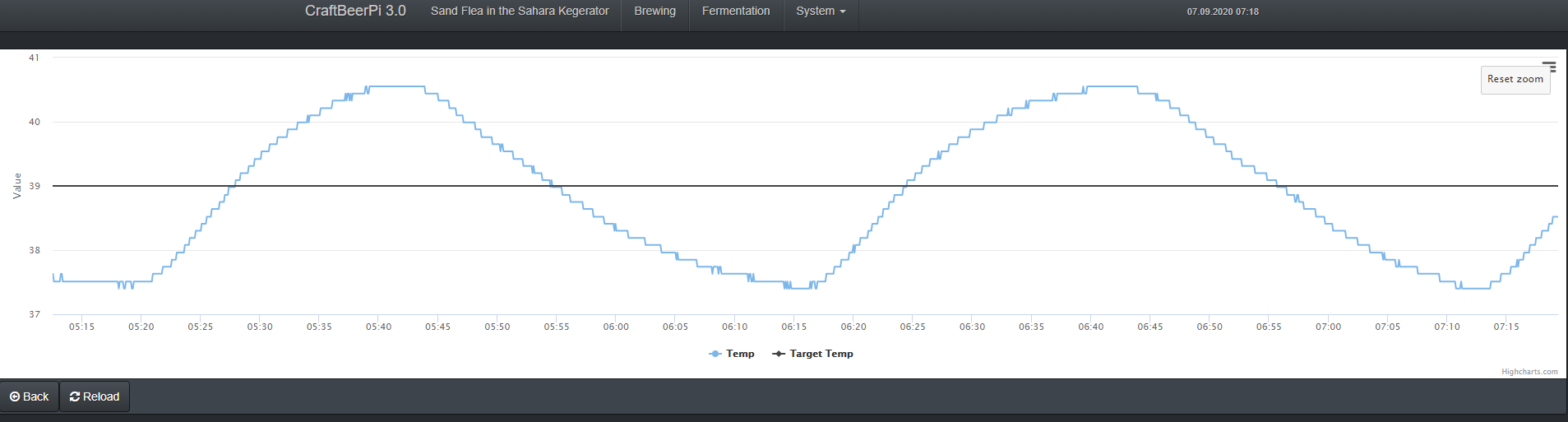

Here's a graph of the temps over the past hour or so. Keep in mind, I have 2 EMPTY kegs in the kegerator and no CO2 tank yet. I have a temp probe taped to one of the kegs and one up into the top of the tower. The tower temp is about 5.5 degrees F higher than the kegerator. I have the kegerator set to 38F now. Tower is 43.5F. Will this change much once I get a full keg(s) in the kegerator? Should I try to lower the tower temp? I could put a copper pipe up into it, extending down into the fridge and running the beer line through it to get it a little colder. Not sure what else I could do.

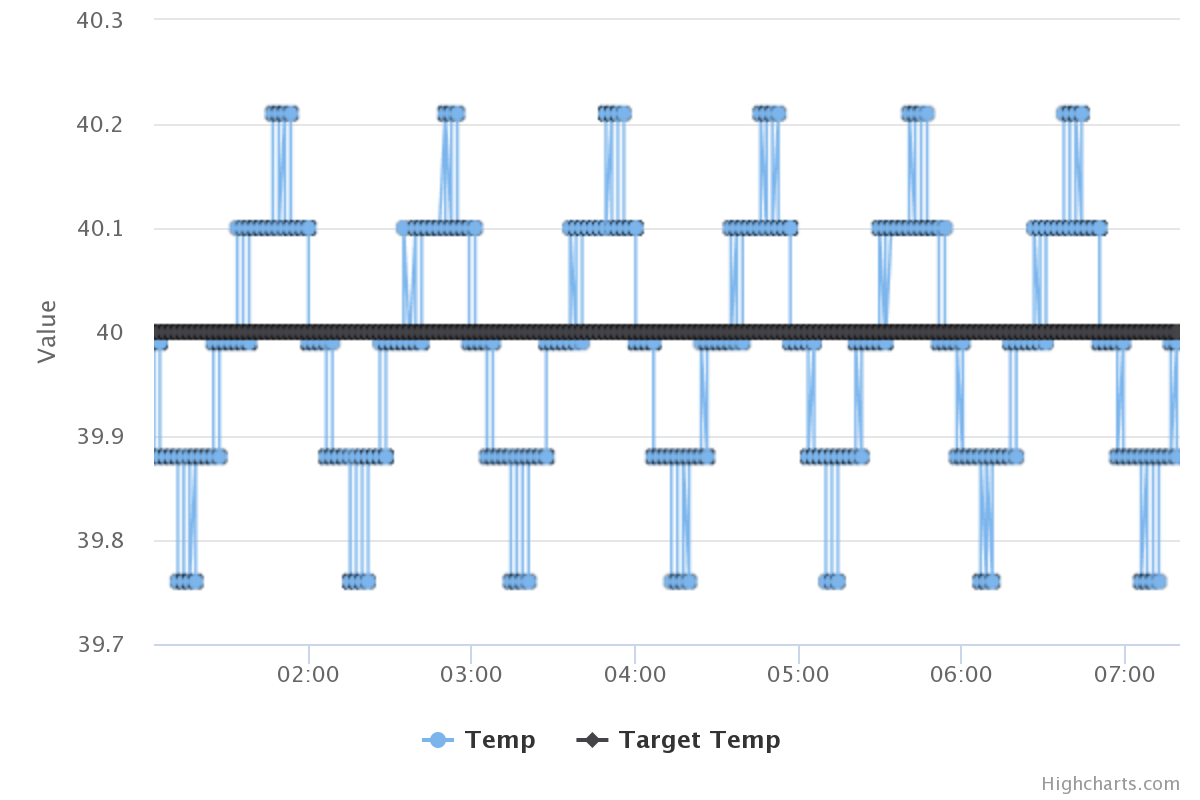

2nd question -- Are these cycle times OK for my kegerator? Not too frequently on/off/on to shorten the life of the compressor or other parts in the kegerator? It appears to cycle about every 5-10 minutes. I think that's OK, thought I'd ask for a second opinion. I suspect it'll probably be a bit better if the kegs are full, right?

The top graph is the Kegerator temp. The bottom graph is the tower temp.

I bought a used kegerator. I switched the control of it over to a CraftbeerPi controller.

I'm wondering about two things before I keg for the first time:

1. Tower temp - how high is too high?

2. Cycle time of the compressor

I put a fan blowing up through a tube into the tower. The temps are cooler, but I'm wondering if still too warm and I'll end up with foamy beer the first pour.

Here's a graph of the temps over the past hour or so. Keep in mind, I have 2 EMPTY kegs in the kegerator and no CO2 tank yet. I have a temp probe taped to one of the kegs and one up into the top of the tower. The tower temp is about 5.5 degrees F higher than the kegerator. I have the kegerator set to 38F now. Tower is 43.5F. Will this change much once I get a full keg(s) in the kegerator? Should I try to lower the tower temp? I could put a copper pipe up into it, extending down into the fridge and running the beer line through it to get it a little colder. Not sure what else I could do.

2nd question -- Are these cycle times OK for my kegerator? Not too frequently on/off/on to shorten the life of the compressor or other parts in the kegerator? It appears to cycle about every 5-10 minutes. I think that's OK, thought I'd ask for a second opinion. I suspect it'll probably be a bit better if the kegs are full, right?

The top graph is the Kegerator temp. The bottom graph is the tower temp.

Last edited: