Finally got my 4gal fermentor. Goign to be doing my first batch tomorrow. Anything special w/r/t cleaning for first use? Instructions say PBW is all that is needed. Worth hitting it with some barkeepers friend?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Anvil Bucket Fermentors

- Thread starter ZmannR2

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

So my first batch with the Anvil 4g is done...sort of. Finished up, whirlpooled, chilled, and trnsfered. And the freakin valve leaks. It's not a leak around the valve, it is leaking through the valve. Not gonna lie...I'm pretty pissed. Emails out voicing my displeasure, hoping I get a decent solution soon.

That's a bummer. I was looking at getting these soon too, let us know what the resolution is. Did you get it direct from Anvil or through a store?So my first batch with the Anvil 4g is done...sort of. Finished up, whirlpooled, chilled, and trnsfered. And the freakin valve leaks. It's not a leak around the valve, it is leaking through the valve. Not gonna lie...I'm pretty pissed. Emails out voicing my displeasure, hoping I get a decent solution soon.

while AZBeer's leaking valve is a total bummer, and i hope that Anvil takes care of his defective bucket, it's also an anomaly. of all the people who have this ferementer he's the first to write in with this issue. let's not blow this out of proportion yet... as a counterpoint, none of my three Anvil buckets leak.That's a bummer. I was looking at getting these soon too, let us know what the resolution is. Did you get it direct from Anvil or through a store?

while AZBeer's leaking valve is a total bummer, and i hope that Anvil takes care of his defective bucket, it's also an anomaly. of all the people who have this ferementer he's the first to write in with this issue. let's not blow this out of proportion yet... as a counterpoint, none of my three Anvil buckets leak.

For sure. And as an update, I have had some communication, and I am hopeful I will get a replacement valve in fairly short order.

No issues at all with mine either. Not sure why you wouldn’t fill it with water and check it for leaks first anyway.

For sure. Probably should have...but I didn't. I cleaned the valve separate, and cleaned the fermenter without filling it. Seems like a no-brainer now.

Update-New valve showed up last night. Props to Austin Homebrew for the quick turnaround on the replacement. Looking at it, the original valve definitely did not have the plastic bushings that seat the ball in the valve.

FTR I wouldn't discourage anyone from the Anvil fermenter. Seems like a good product, and Bilchmann/ Anvil is a good company. This one just got through QA.

FTR I wouldn't discourage anyone from the Anvil fermenter. Seems like a good product, and Bilchmann/ Anvil is a good company. This one just got through QA.

Thought I would add my name to this thread because I have the 4 Gal Fermenter and while I love it so far, I realized I was starting to "misplace" about a quart or two of liquid post boil.... everything checks out pre-boil then suddenly I'm losing a lot more liquid to boil off (or so I thought) based on the markings on the inside of the fermenter...

and then I read this thread.....

Oh boy.. I'm going to have to measure once this ESB is out of the fermenter to see if I'm going insane or if Anvil (which based on what I've read so far) are being silly with their markings..

Cheers,

Dave

and then I read this thread.....

Oh boy.. I'm going to have to measure once this ESB is out of the fermenter to see if I'm going insane or if Anvil (which based on what I've read so far) are being silly with their markings..

Cheers,

Dave

Update-New valve showed up last night. Props to Austin Homebrew for the quick turnaround on the replacement. Looking at it, the original valve definitely did not have the plastic bushings that seat the ball in the valve.

FTR I wouldn't discourage anyone from the Anvil fermenter. Seems like a good product, and Bilchmann/ Anvil is a good company. This one just got through QA.

Just coming back to this thread and specifically regarding the leaky valve per AZBeer - after this batch is done I’ll verify my bucket as I noted, just this morning, there was a small/minor leak (more like a drop or two) - it may be the same issue OR it may not be the same issue - regardless, it didn’t leak on the previous (first) batch so I think this may just be me being overly cautious/concerned.

Cheers,

Dave

i got the slightest of drips on one of my buckets while i was cleaning it with PBW. i figured out that i hadn't sufficiently tightened the spigot to the bucket. a balance is needed: too loose and it can drip/leak; but too tight and you won't be able to rotate the pickup tube. it took me about 15 seconds to figure out, haven't had a prob since.just this morning, there was a small/minor leak (more like a drop or two) - it may be the same issue OR it may not be the same issue - regardless, it didn’t leak on the previous (first) batch so I think this may just be me being overly cautious/concerned.

i got the slightest of drips on one of my buckets while i was cleaning it with PBW. i figured out that i hadn't sufficiently tightened the spigot to the bucket. a balance is needed: too loose and it can drip/leak; but too tight and you won't be able to rotate the pickup tube. it took me about 15 seconds to figure out, haven't had a prob since.

Ya... that's what I'm figuring is the "issue" - I'll just wait till this ESB is done (in a couple weeks) and then after cleaning it out.. just check the tolerances for the spigot

Regardless, I do love the size on the small one (4 Gallon) - Makes me want to get at least one more - so much easier even if used as a secondary (i.e. fruit or such on the bottom and rack the beer on top) or to dry hop with...

Cheers,

Dave

Coming back to this as I bottled my ESB yesterday.

I measured out 2 Gallons and 2.5 Gallons (since I do 2.5 Gallon batches) and, sure enough, it’s coming up short on the Anvil. I THOUGHT, based on what I was seeing, I was losing wort somewhere but, it seems, my calculations were correct and the measurement was incorrect.

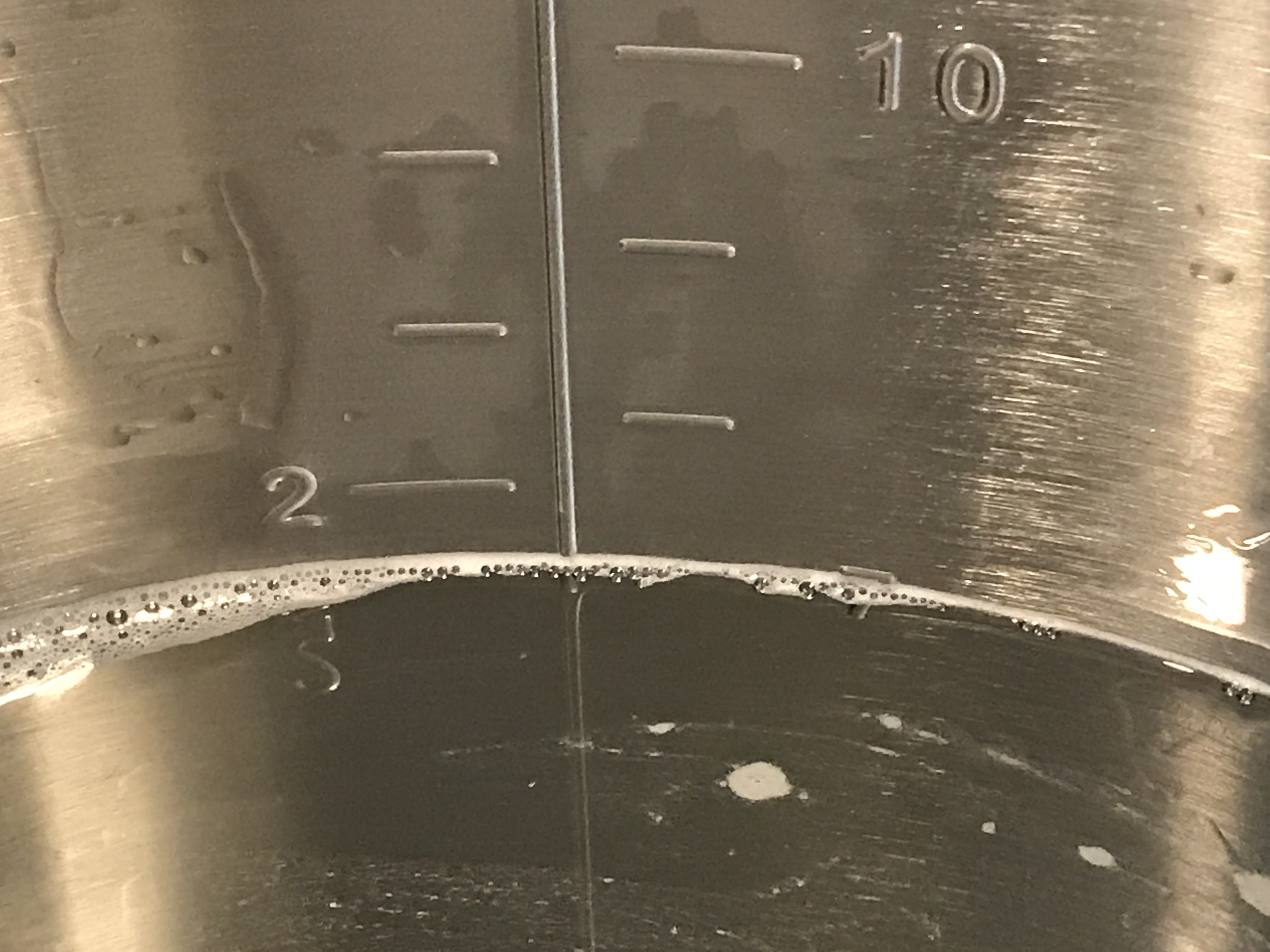

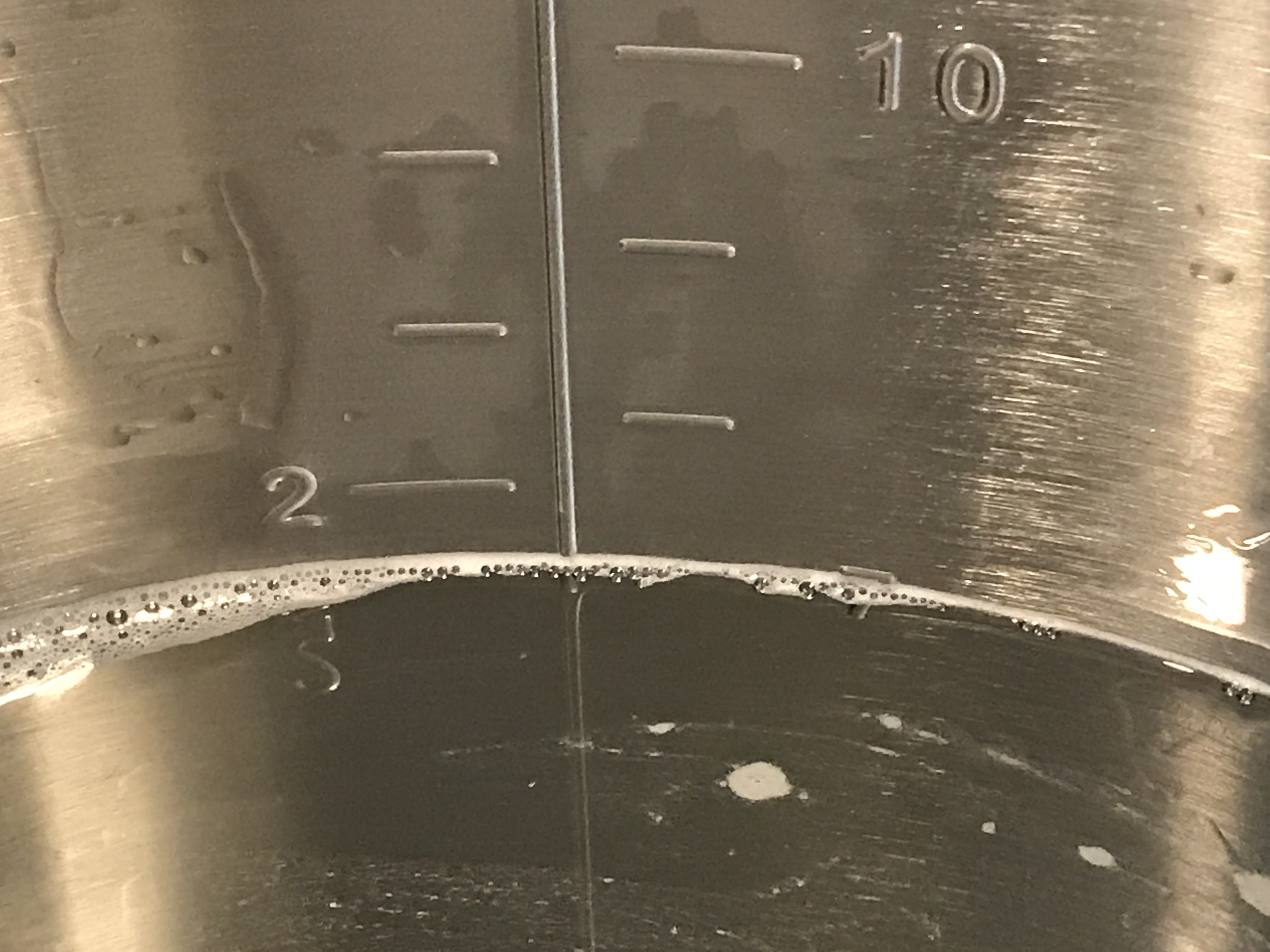

The above is what 2 Gallons looks like - note where the “2” is on the Anvil fermenter (4 Gallon fermenter).

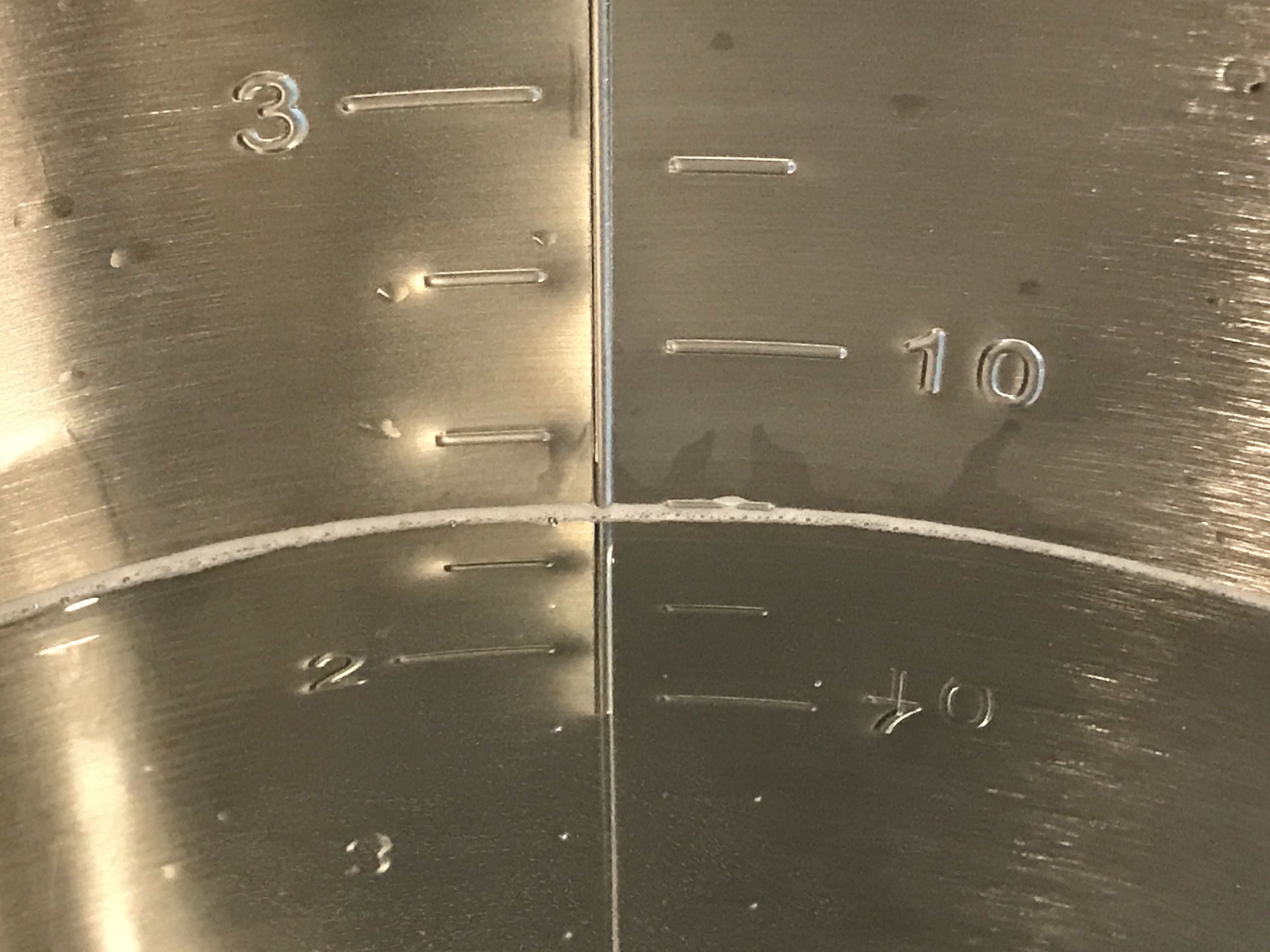

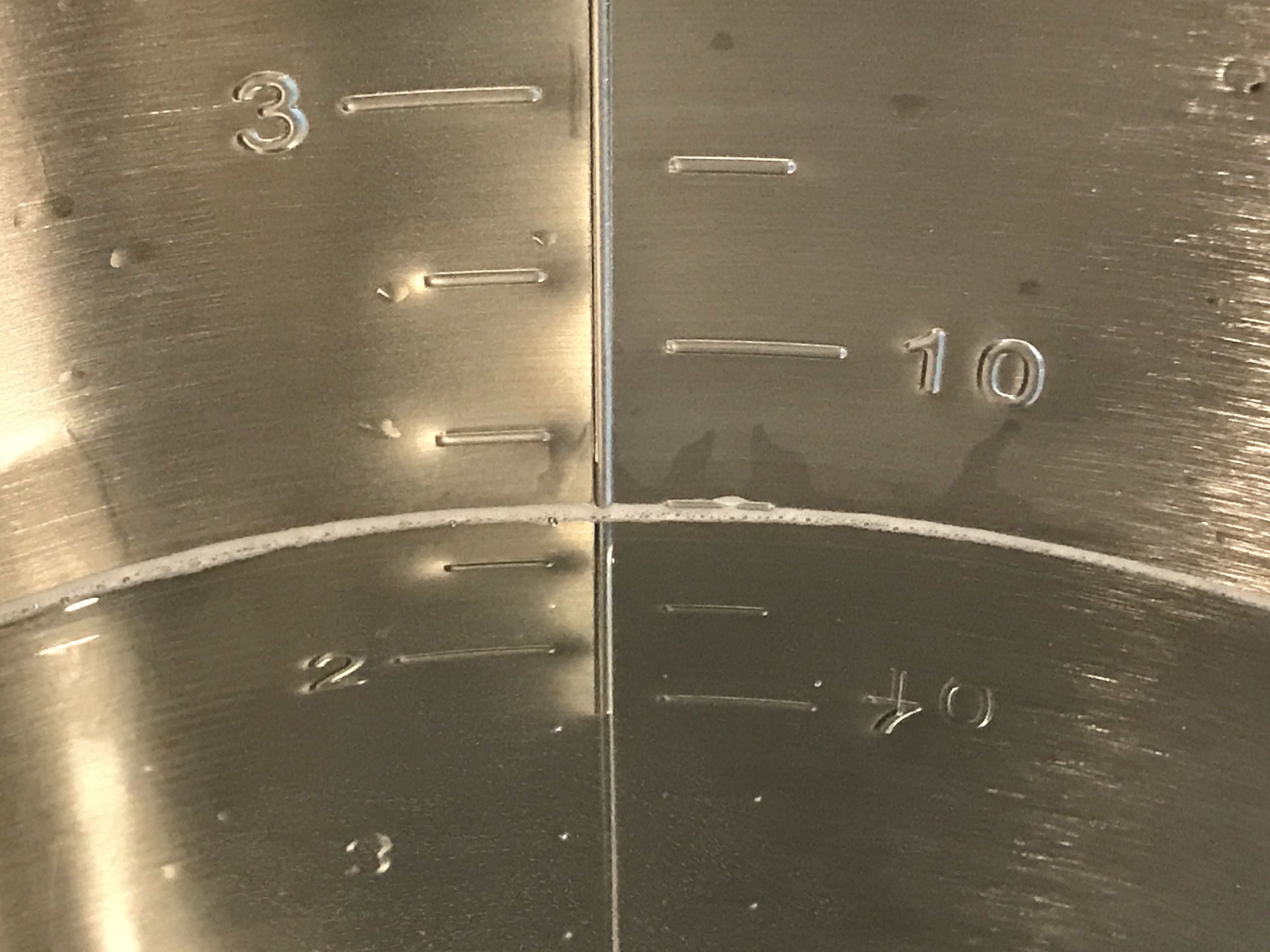

This (above) is what 2.5 Gallons looks like note where the gallon lines are (on the left) and the litre lines are (on the right) - even the litre lines are incorrect - that reads 9 litres whereas 2.5 Gallons is 9.46 Litres (more like 9.5)

So there you have it - markings on the Fermenter are not to be believed

Cheers,

Dave

I measured out 2 Gallons and 2.5 Gallons (since I do 2.5 Gallon batches) and, sure enough, it’s coming up short on the Anvil. I THOUGHT, based on what I was seeing, I was losing wort somewhere but, it seems, my calculations were correct and the measurement was incorrect.

The above is what 2 Gallons looks like - note where the “2” is on the Anvil fermenter (4 Gallon fermenter).

This (above) is what 2.5 Gallons looks like note where the gallon lines are (on the left) and the litre lines are (on the right) - even the litre lines are incorrect - that reads 9 litres whereas 2.5 Gallons is 9.46 Litres (more like 9.5)

So there you have it - markings on the Fermenter are not to be believed

Cheers,

Dave

muledogus

Well-Known Member

- Joined

- Mar 12, 2018

- Messages

- 133

- Reaction score

- 83

Yeah they are off in the bigger ones too. I'm not sure if it's just a giant mistake or if they think they are giving us some kind of way to hit our target volumes after trub loss. I.E. fill wort to 2.5 gallon mark and though it's off, when you rack you actually end up with 2.5 gallons of beer. Not sure the measurements are off enough for that to be accurate either but I have no explanation why else they would have this issue.

This is almost exactly what I was just thinking. Anyone every try this? It would be great to have a TC fitting on the lid for pressure transfers, dry hop, blow off, etc. Anyone have a measurement on the bung hole? I was thinking this piece might work:If the hole is 1-3/8 ish it should be easy to solder a TC fitting on or even do it weldless with a 1" NPT to 1-1/2" TC adapter from Brew Hardware. Then there's all sort of options for what to put on top.

https://www.brewhardware.com/product_p/tc15wlf.htm

EDIT: Just looked back and saw this was discussed and that the hole would have to be expanded. Anyone try this or figure some way to put a TC on that lid hole?

Last edited:

Actually, I think you'd have to figure a way to measure the density of your wort, and not use the density of water! The 8.34 lb/gal would most likely be used for pure water, and might be a good 'round figure' but I have no idea how you would measure the density of each and every wort you put into it!Lol, Anvil told me the markings are by weight not volume. So I guess we need to weigh out the gallons by 8.34lb per gal and the marks will be correct?

If you use the markings (I don't), then you could just make your own by etching (there's an article on HBT here somewhere), or get a 3/8" or 1/2" x 18 or 24" stainless tube and make your own "marking stick" to do the job; this seems to me to be the best/cheapest option.

If you want to get real extravagant, I suppose you could DIY a closed-in sight glass, but to me that would be counter-productive for a fermenter! LOL

Last edited:

BTW, I looked at the Chapman fermenters ... $119 for a 7 gallon sounds good for a low-cost fermenter, --there may be better deals that I don't know about,-- I just looked it up becuz someone in the thread mentioned it. The few differences between that fermenter and my Big Mouth Bubblers are:

mine will break if they are dropped becuz they're glass

my BBB's are a 1/2 gallon smaller

my BBB's are $100 less in price (Almost he price of two BBB's)

They both have a flat bottom, but the Chapman can be drilled for a bottom outlet to dump the yeast, hop sludge, and other trub, (yes, you'd have to weld on some legs or build a stand for it). I have to muscle the heavy, fragile glass jug around to get rid of the trub (I don't like plastics, been there, done that!). If I knew more about the quality and integrity of the BBB's, I could drill the holes for a side and bottom tap, but I believe they are hand blown into a form, so they probably wouldn't handle the stress.

Unless I end up breaking my glass fermenters, I'll keep on keepin' on; BUT, if the opportunity/wealth presents itself, I'll get the right accessories to ferment in cornies or splurge for an Anvil or a Chapman! As someone pointed out above, the fold-down handles and the $120 price tag is a huge incentive to go with the Chapman instead of the Anvil, even if you're only saving a saw-buck!

I'm going to wait to see if there are any other problems with either one, but I see the 7.5 gallon Anvil and the 7 gallon Chapman as viable options for small-batch/small-income brewing!

mine will break if they are dropped becuz they're glass

my BBB's are a 1/2 gallon smaller

my BBB's are $100 less in price (Almost he price of two BBB's)

They both have a flat bottom, but the Chapman can be drilled for a bottom outlet to dump the yeast, hop sludge, and other trub, (yes, you'd have to weld on some legs or build a stand for it). I have to muscle the heavy, fragile glass jug around to get rid of the trub (I don't like plastics, been there, done that!). If I knew more about the quality and integrity of the BBB's, I could drill the holes for a side and bottom tap, but I believe they are hand blown into a form, so they probably wouldn't handle the stress.

Unless I end up breaking my glass fermenters, I'll keep on keepin' on; BUT, if the opportunity/wealth presents itself, I'll get the right accessories to ferment in cornies or splurge for an Anvil or a Chapman! As someone pointed out above, the fold-down handles and the $120 price tag is a huge incentive to go with the Chapman instead of the Anvil, even if you're only saving a saw-buck!

I'm going to wait to see if there are any other problems with either one, but I see the 7.5 gallon Anvil and the 7 gallon Chapman as viable options for small-batch/small-income brewing!

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Are you guys considering the dead space in these? If you add three gallons to their markings. Can you drain out three gallons?

It seems like it's low by your comparison to three gallons added. It might be that the dead space is assumed to be lost wort.

Yes/No?

It seems like it's low by your comparison to three gallons added. It might be that the dead space is assumed to be lost wort.

Yes/No?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Pulled the trigger for two today!

Well.. there is a bit of "dead space" in the fermenter (it's got a slight cone but it's not a "conical" per se) - so did they take that into account? Well, that would mean I would have to take that into account - and that would mean that they would have to tell me that they're actually measuring from a specific point in the fermenter - and they never "said" any of that (either by literature, their online info etc.)Are you guys considering the dead space in these? If you add three gallons to their markings. Can you drain out three gallons?

It seems like it's low by your comparison to three gallons added. It might be that the dead space is assumed to be lost wort.

Yes/No?

That said, I will reiterate that it's a GREAT fermenter for the price. Would I have liked the SS Brewtech? Sure... but it's a lot more spendy, it doesn't have any handles (the 3.5 gallon one) and right now.. the Anvil suits what I want/need.

I may get the 7.5 gallon one but I'm going to wait and see what else there is out there at that size.

Cheers,

Dave

I'm guessing that someone in their ordering/supply chain screwed up, and that's why the markings are where they are. That said, I also (personally) don't care all that much. It's a fermenter, not a kettle, and I generally don't experience much evaporation during fermentation.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Well.. there is a bit of "dead space" in the fermenter (it's got a slight cone but it's not a "conical" per se) - so did they take that into account? Well, that would mean I would have to take that into account - and that would mean that they would have to tell me that they're actually measuring from a specific point in the fermenter - and they never "said" any of that (either by literature, their online info etc.)

That said, I will reiterate that it's a GREAT fermenter for the price. Would I have liked the SS Brewtech? Sure... but it's a lot more spendy, it doesn't have any handles (the 3.5 gallon one) and right now.. the Anvil suits what I want/need.

I may get the 7.5 gallon one but I'm going to wait and see what else there is out there at that size.

Cheers,

Dave

I Totally Agree! It's a great bargain.

For what it's worth, I rarely use the fermenter graduations. I typically use a steel rule in my boil kettle as to when to start the 60 minute boil timer. Boil at the #8 heat setting on the electric range for the duration. It evaporates out at a constant rate. On an all grain batch I'm not about to water down wort or dump a little wort just to a hit a mark on the pail. So why worry about that unless you're a partial boil extract user. I think the dead space is a important consideration none the less. AG or extract. Assuming you want to get 5 gallons out to a keg. Would it not suck to have more beer than what would fit in keg?

That point put aside....

I bought two 7.5g fermenters because of the price point over SS Brew Bucket. I liked the idea of stackability of two fermenters with SS Brew Tech. The price is what got me after eyeing the Brew bucket for nearly a year.

I don't crash chill. I age two to three weeks ferm temps then keg. I want to rid myself of the auto siphon. I could care less if they fit in a refrigerator. Three kegs fits in the keezer and that's all that matters.

I have to admit I'm attracted to shiny objects. My brewery is in my work apartment kitchen. These will sit next to the keezer on the table top for all guests to see. Kind of like the local brewery with fermenters out on display.

I have two residences; work and home. The wife would NOT tolerate these in her kitchen. She's not so impressed about shiny things full of beer.

[emoji1]

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

This is what I was thinking.... final volume.Yeah they are off in the bigger ones too. I'm not sure if it's just a giant mistake or if they think they are giving us some kind of way to hit our target volumes after trub loss. I.E. fill wort to 2.5 gallon mark and though it's off, when you rack you actually end up with 2.5 gallons of beer. Not sure the measurements are off enough for that to be accurate either but I have no explanation why else they would have this issue.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Lol, Anvil told me the markings are by weight not volume. So I guess we need to weigh out the gallons by 8.34lb per gal and the marks will be correct?

This seems like a BS answer from some anvil customer service rep.

Since I'm an engineer, I'll geek-out in normal fashion and explain...

It's a given fact, gallons and liters are a volumetric measurement.

A gallon is 231 cubic inches. Volume is area times the depth vertically.

Pi = 3.14159

r = radius of the bucket or 1/2 the diameter. (Units are inches)

Area = 3.14159 * r² (Units are square inches)

11" diameter bucket is 5.5" radially.

5.5² = 30.25 in²

Area is 3.14159 x 30.25 in² = 95.0331 in².

h = height of the liquid. (Units are in inches)

Volume = 3.1459 * r² * h (units cubic inches)

Assume the kettle liquid depth is 10.875" deep

95.0331 in² x 10.875" =1033.4849 in³

1033.4849 in³ / 231in³ = 4.4739 gallons.

The level markings absolutely have to be volumetric.

The density of the liquid not a factor here as to the markings on bucket.

Density is a measure of mass (weight) divided by volume.

Density = m/v

This is why a hydrometer has a weight and a measure of volumetric displacement. The more dense or higher the gravity of said liquid the less the hydrometer gets displaced. The less dense or lower the gravity of said liquid the more it gets displaced.

Edit: The fermentor has cone bottom not a spherical...

I think the fermenter depth measurement starts at the tangent point of the cone. Where the cone and the straight edge wall of the fermenter meet. Basically, the top part of the conical up to the graduation lines.

The conical section is a volumetric loss. Thus lowering the measured volume in the fermenter. I doubt they did a volume of a cone calculation for the graduation marks.

V = π * r^2 (h/3)

It's dead space and it varies by how much you turn the racking tube during the siphoning.

It's a guaranteed loss unless you over fill.

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

bless Anvil is quick. I got these in 24 hours!!!!

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

I think I got one of those bad valves. The seal is spun on the wet side of the valve.

Posting four pictures. Two with the spun seal, one with the ball open and one closed, then two with a normal seated seal, one open and closed.

It's a shame that I have to call them. At least I have one that's good. It shouldn't stop me from brewing this week.

Posting four pictures. Two with the spun seal, one with the ball open and one closed, then two with a normal seated seal, one open and closed.

It's a shame that I have to call them. At least I have one that's good. It shouldn't stop me from brewing this week.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

I have a similar problem with one of my valves. The seal is not seated correctly. I hope Anvil handles it the same way as Austin did for you.Update-New valve showed up last night. Props to Austin Homebrew for the quick turnaround on the replacement. Looking at it, the original valve definitely did not have the plastic bushings that seat the ball in the valve.

FTR I wouldn't discourage anyone from the Anvil fermenter. Seems like a good product, and Bilchmann/ Anvil is a good company. This one just got through QA.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Just spoke to Anvil. They're sending me a new one.

- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

View attachment 547072 Just brewed my first batch into the four gallon bucket. So far, so good.

Can you snap another pic of your stopper? It looks like you have a 2 hole with a thermowell... this is exactly what I want to add to mine and wanted to see a better picture so I can replicate.

muledogus

Well-Known Member

- Joined

- Mar 12, 2018

- Messages

- 133

- Reaction score

- 83

Can you snap another pic of your stopper? It looks like you have a 2 hole with a thermowell... this is exactly what I want to add to mine and wanted to see a better picture so I can replicate.

Didn’t quote me but I have the same setup. I originally drilled my own #7 stopper with 2 holes but was worried how jagged they were so I ended up ordering a pre-made one off of amazon.

https://www.amazon.com/dp/B01KP4D0K2/?tag=skimlinks_replacement-20

Last edited by a moderator:

- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

Awesome! I went ahead and just bought that product as well to keep things easy. Hard to argue with the price.Didn’t quote me but I have the same setup. I originally drilled my own #7 stopper with 2 holes but was worried how jagged they were so I ended up ordering a pre-made one off of amazon.

https://www.amazon.com/dp/B01KP4D0K2/?tag=skimlinks_replacement-20

Last edited by a moderator:

- Joined

- Nov 19, 2017

- Messages

- 250

- Reaction score

- 93

To anyone that is curious about closed pressure transfers with the Anvil fermenter, I contacted Anvil and they sent me this:

"We haven't tried it but the lid was not designed to withstand pressure and we didn't provide any other type of safety relief I over pressured. Sorry"

So, it looks like it wasn't specifically designed to support pressure transfers, but with the right hardware and only 1-2psi, I'm still convinced it could work. One way to find out, right?

"We haven't tried it but the lid was not designed to withstand pressure and we didn't provide any other type of safety relief I over pressured. Sorry"

So, it looks like it wasn't specifically designed to support pressure transfers, but with the right hardware and only 1-2psi, I'm still convinced it could work. One way to find out, right?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Right, you could use a propane regulator to keep the pressure low and constant.To anyone that is curious about closed pressure transfers with the Anvil fermenter, I contacted Anvil and they sent me this:

"We haven't tried it but the lid was not designed to withstand pressure and we didn't provide any other type of safety relief I over pressured. Sorry"

So, it looks like it wasn't specifically designed to support pressure transfers, but with the right hardware and only 1-2psi, I'm still convinced it could work. One way to find out, right?

i'm using the exact same thermowell, as part of this package: https://www.amazon.com/gp/product/B01N37ATGL/?tag=skimlinks_replacement-20. when i bought it 2 months ago, it was $50.... pic of them in action here.Didn’t quote me but I have the same setup. I originally drilled my own #7 stopper with 2 holes but was worried how jagged they were so I ended up ordering a pre-made one off of amazon.

https://www.amazon.com/dp/B01KP4D0K2/?tag=skimlinks_replacement-20

i certainly wouldn't hesitate to try it. i can't see how a few PSI could cause any issue (other than maybe popping out the stopper if not jammed in sufficiently... such woe).To anyone that is curious about closed pressure transfers with the Anvil fermenter, I contacted Anvil and they sent me this:

"We haven't tried it but the lid was not designed to withstand pressure and we didn't provide any other type of safety relief I over pressured. Sorry"

So, it looks like it wasn't specifically designed to support pressure transfers, but with the right hardware and only 1-2psi, I'm still convinced it could work. One way to find out, right?

i currently have my second batch in my Anvil buckets. cleaning after the first batch was a breeze, took just a few minutes per bucket.

Last edited by a moderator:

apl_seed

apl_seed

The valves can't be broken down into individual pieces? So if the seal slips, you can't just break it down and align everything back up.

I have a similar problem with one of my valves. The seal is not seated correctly. I hope Anvil handles it the same way as Austin did for you.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

The valves can't be broken down into individual pieces? So if the seal slips, you can't just break it down and align everything back up.

I think you can. However, they opted to send a replacement. In fact I think you have too be able to disassemble. How would you get the seal seated?

It's looks like the main body of the valve is in two pieces. Look to the seam just to right of the 1/2" Mark.

Last edited:

apl_seed

apl_seed

Yea, it looks like it splits in half. I was thinkin the ball might pop out after you got it apart and than the seals could have a grooves they fit into. I have a valve that does that on my BK. Two teflon seals on both sides of the ball that go into grooves. Than when you tighten the two haves everything snugs up nice. Hopefully you can do that in case they slip again.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

@apl_seed

I busted it apart tonight. It came apart pretty easily. The seal was a bit buggered up from being squished half out of place. I managed to re-center the seal and quickly tighten the male part to re-seat the seal.

It's doable. Frankly if you put a drill bit into the valve with the ball open so it ran all the way through. There's no reason you can't drop the seal over the drill bit followed by the male half of the valve body and hand tighten until its snug, tighten it with two wrenches. Then remove the drill bit. It'd be perfectly centered.

I busted it apart tonight. It came apart pretty easily. The seal was a bit buggered up from being squished half out of place. I managed to re-center the seal and quickly tighten the male part to re-seat the seal.

It's doable. Frankly if you put a drill bit into the valve with the ball open so it ran all the way through. There's no reason you can't drop the seal over the drill bit followed by the male half of the valve body and hand tighten until its snug, tighten it with two wrenches. Then remove the drill bit. It'd be perfectly centered.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,910

Two Anvil's filled;

- Cascade Pale Ale -NEIPA Style

- Gratzer (Prussian) or Grodziske (Polish) - Oak Smoked Wheat Beer, as in oakey, smokey lawn mower bier/pivo.

Drinking Polish Wąsosz ... Basically a Wheat Beer from Konopiska Poland.

- Cascade Pale Ale -NEIPA Style

- Gratzer (Prussian) or Grodziske (Polish) - Oak Smoked Wheat Beer, as in oakey, smokey lawn mower bier/pivo.

Drinking Polish Wąsosz ... Basically a Wheat Beer from Konopiska Poland.

Last edited:

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 29

- Views

- 1K