Earlier this year, I came across some Conviron Temperature chambers for sale on craigslist. I wanted to regulate fermentation better and had been looking around for several months for something reasonable. What I found was essentially lab-grade temperature/humidity and light controlled chambers used for plant cell growth. A local lab used them for seedling starts in a study they did, but upgraded and were selling them (Still one left at $300 if anyone wants it, located in Portland, OR area).

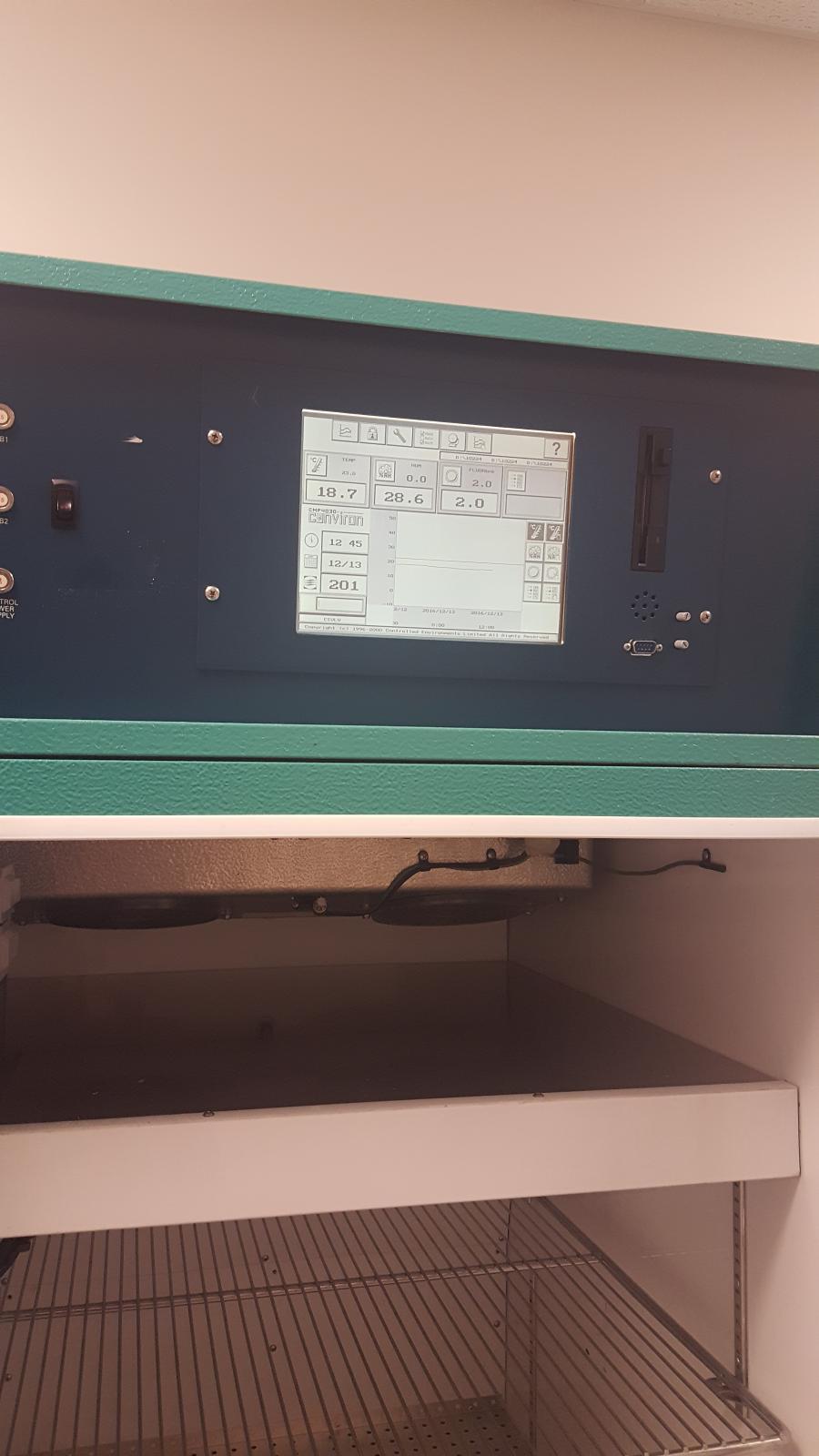

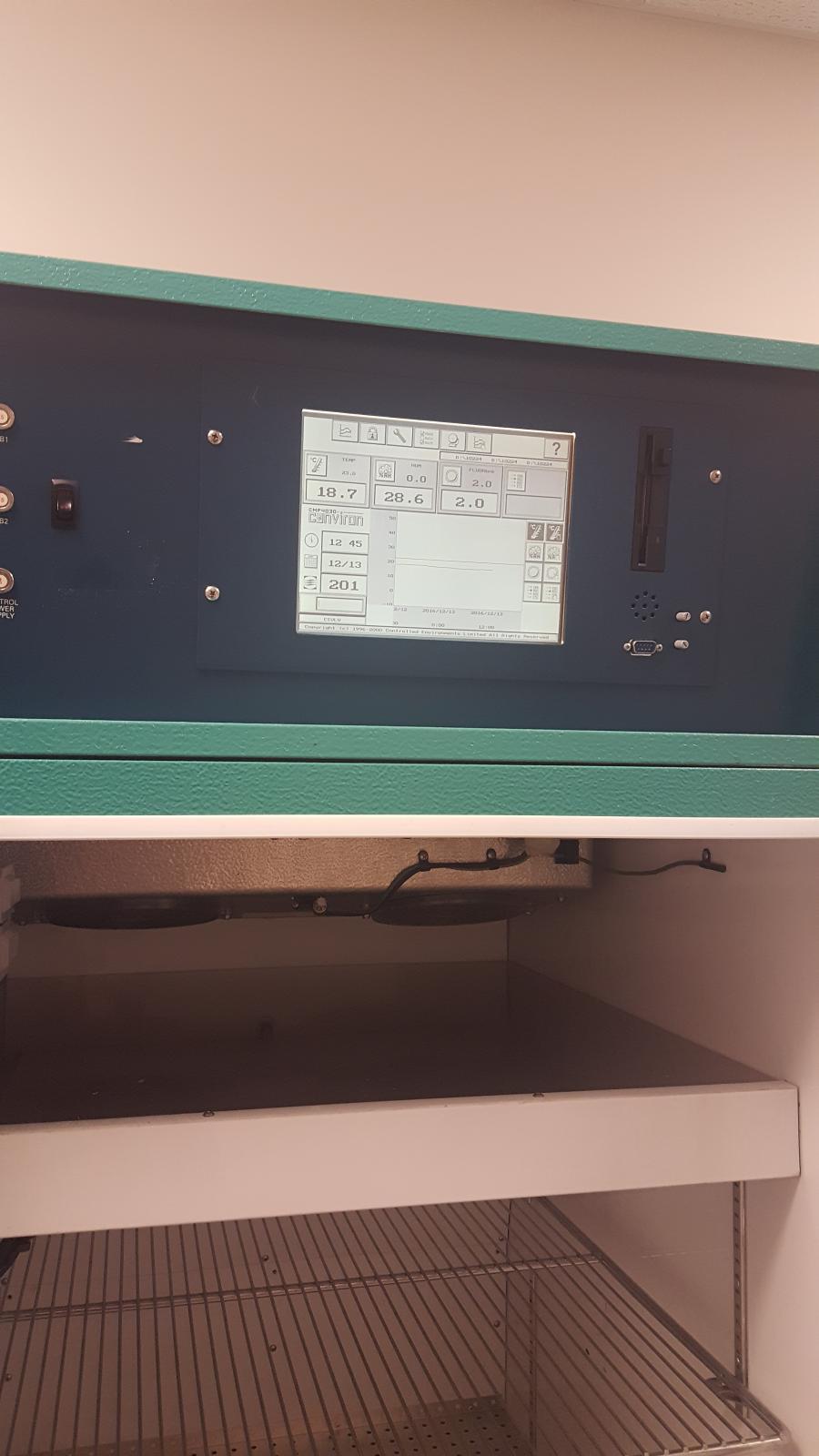

Anyway, the Chambers, while a little old, were touchscreen controlled and can run programs for varying the temp/humidity/light. Outdated for sure, as they had an old PC104 SBC computer and Floppy disk drives. The chambers themselves are HUGE, and can fit 8-9 corny kegs in the bottom level.

I went to take a look, and 2 of the 3 worked. I made an offer for $400 for one working and one not-working as gamble. I got them home, plugged them in, and one worked just fine. The other, after digging some, had a completely fried motherboard due to an actual Bug. No replacement could be found, so I figured I'd gut the controls and put my own in.

I decided that I would not touch the working one for now, and use as a fermentation chamber, and maybe even dabble in Mycology again (I used to grow Oyster and Shiitake). The other one, would be modified to be used as a big kegerator/beer fridge.

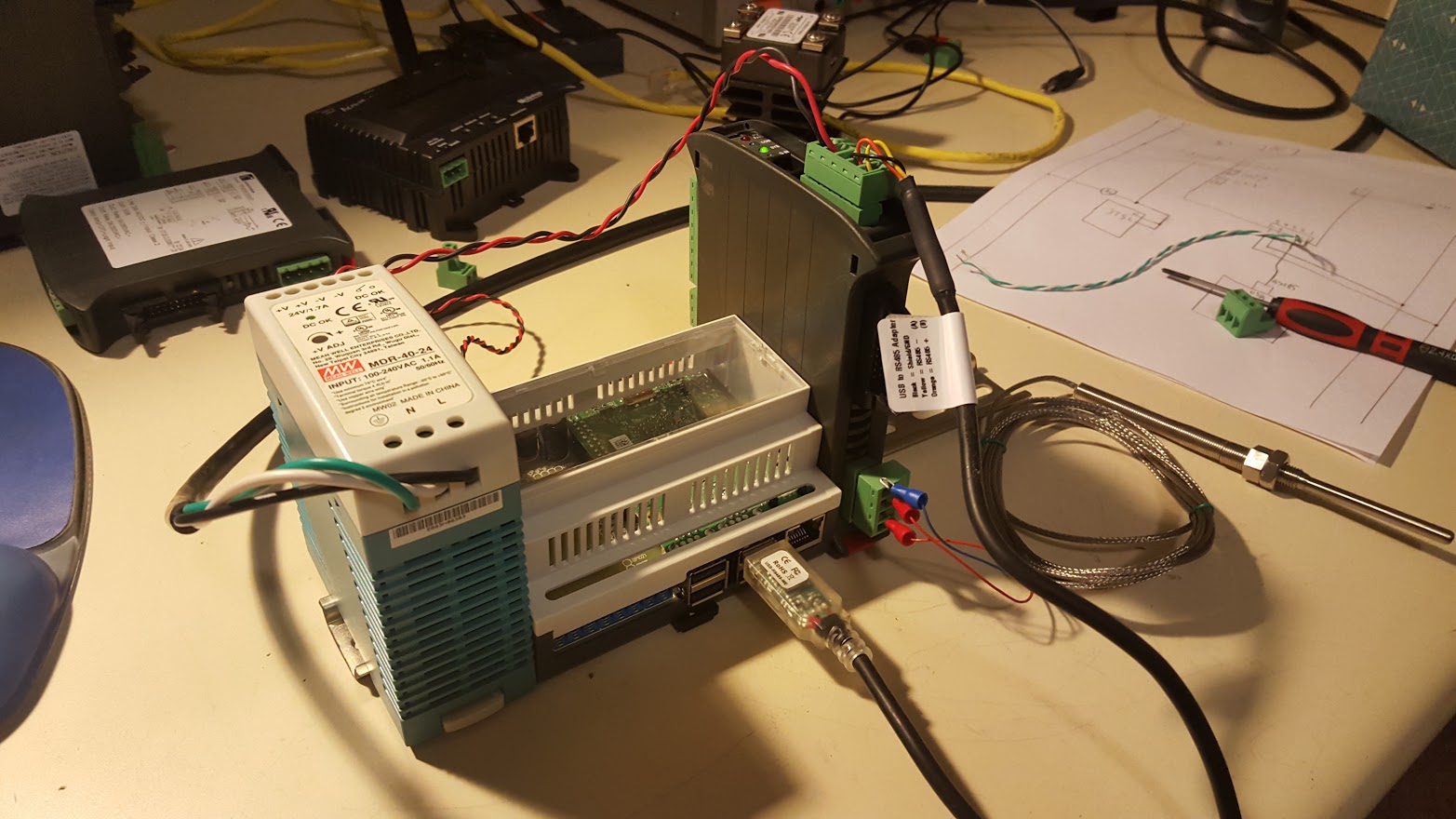

Just like I did on my brew controller (still finishing it up), I decided to use a Raspberry pi and some Modbus PID temperature controllers. The compressor, fans, and even heater inside were saved, as well as some alarming features for low/high temp, and the rest was gutted.

This last weekend, I started working on it more aggressively because I have a beer I need to serve in a couple weeks when it's finished. I added 4 Intertap SS Faucets/Shanks and an ACU Precision Sheet Metal Drip tray and mounted it into the door.

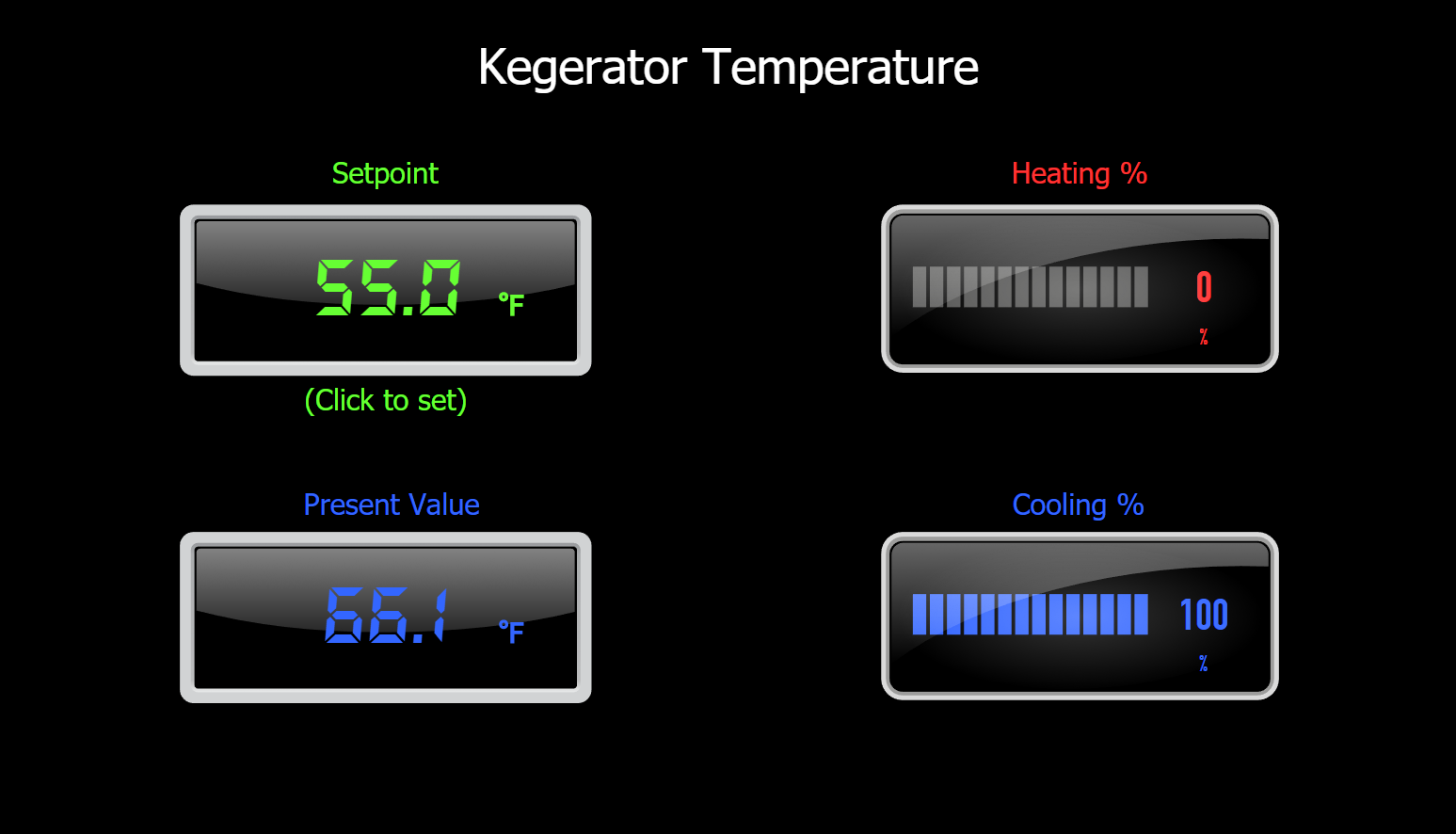

Working on the controls now. I can turn the Fans on and plug in the compressor, just need to install a new temperature sensor and my controls along with a solid state relay. The Pi will run some control software as well as Rasbperry Pints or Taplist.io or something similar on a 7" Touchscreen.

Anyway, the Chambers, while a little old, were touchscreen controlled and can run programs for varying the temp/humidity/light. Outdated for sure, as they had an old PC104 SBC computer and Floppy disk drives. The chambers themselves are HUGE, and can fit 8-9 corny kegs in the bottom level.

I went to take a look, and 2 of the 3 worked. I made an offer for $400 for one working and one not-working as gamble. I got them home, plugged them in, and one worked just fine. The other, after digging some, had a completely fried motherboard due to an actual Bug. No replacement could be found, so I figured I'd gut the controls and put my own in.

I decided that I would not touch the working one for now, and use as a fermentation chamber, and maybe even dabble in Mycology again (I used to grow Oyster and Shiitake). The other one, would be modified to be used as a big kegerator/beer fridge.

Just like I did on my brew controller (still finishing it up), I decided to use a Raspberry pi and some Modbus PID temperature controllers. The compressor, fans, and even heater inside were saved, as well as some alarming features for low/high temp, and the rest was gutted.

This last weekend, I started working on it more aggressively because I have a beer I need to serve in a couple weeks when it's finished. I added 4 Intertap SS Faucets/Shanks and an ACU Precision Sheet Metal Drip tray and mounted it into the door.

Working on the controls now. I can turn the Fans on and plug in the compressor, just need to install a new temperature sensor and my controls along with a solid state relay. The Pi will run some control software as well as Rasbperry Pints or Taplist.io or something similar on a 7" Touchscreen.