sam_cotter

Active Member

- Joined

- Aug 21, 2016

- Messages

- 40

- Reaction score

- 14

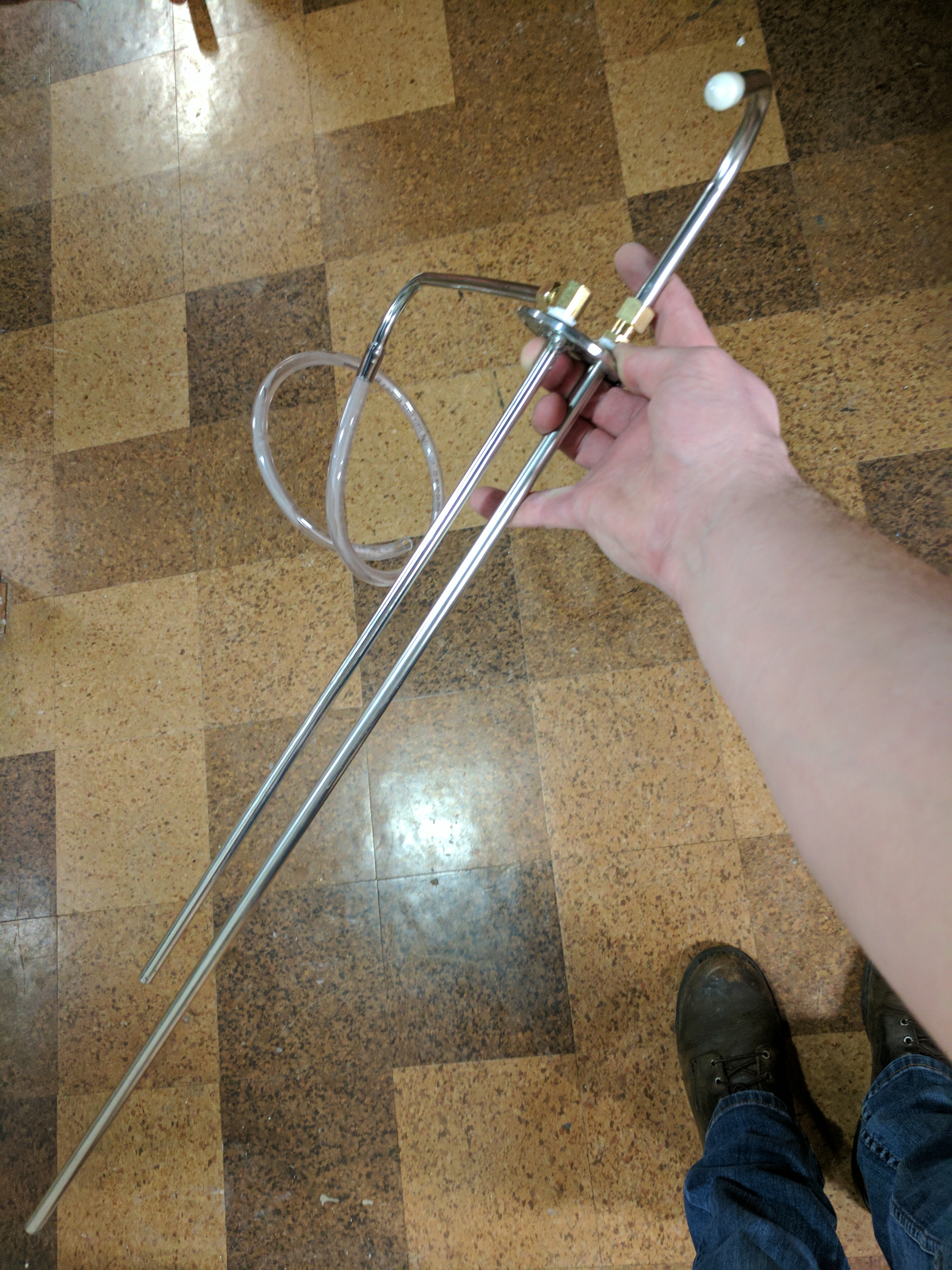

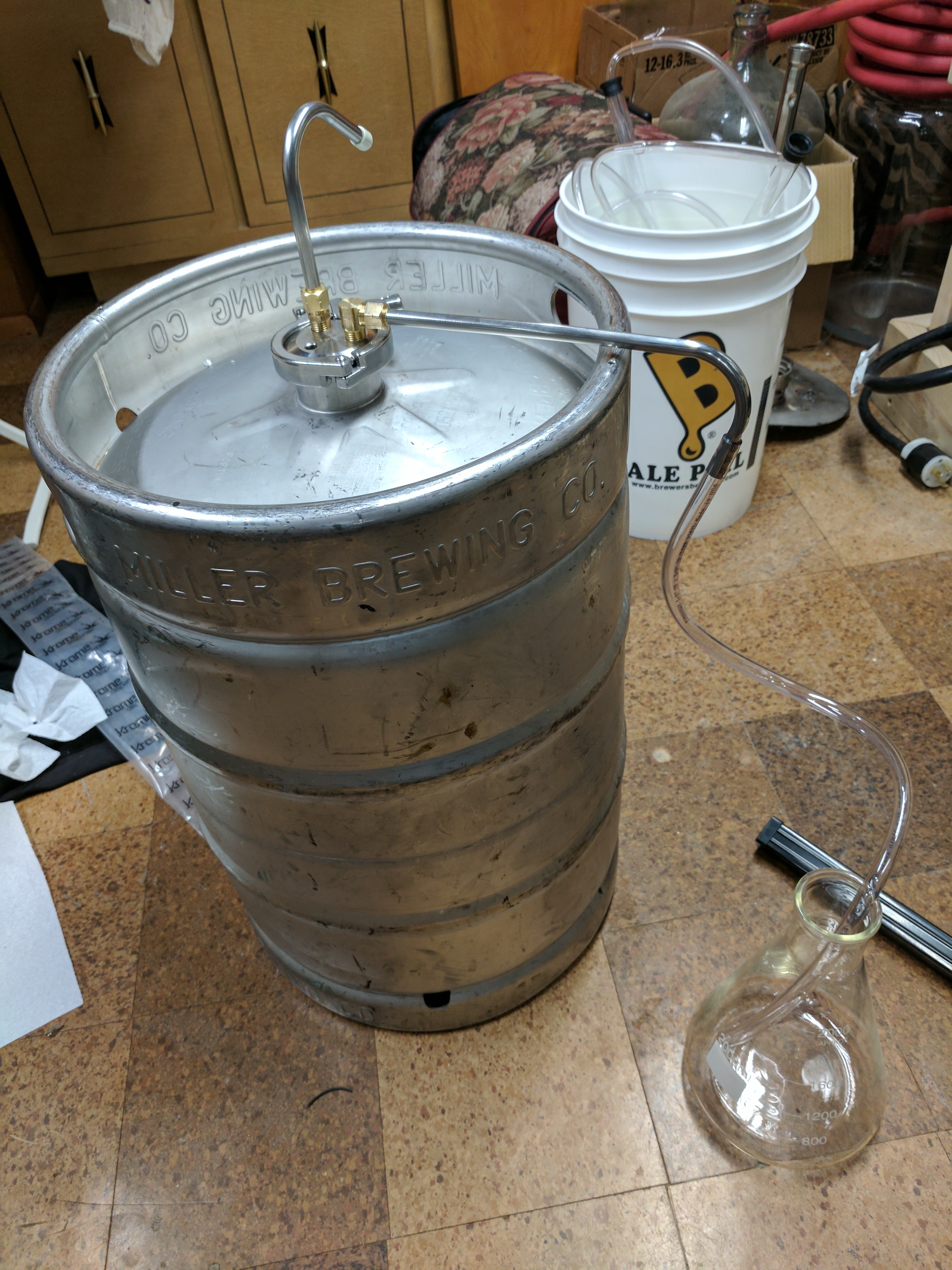

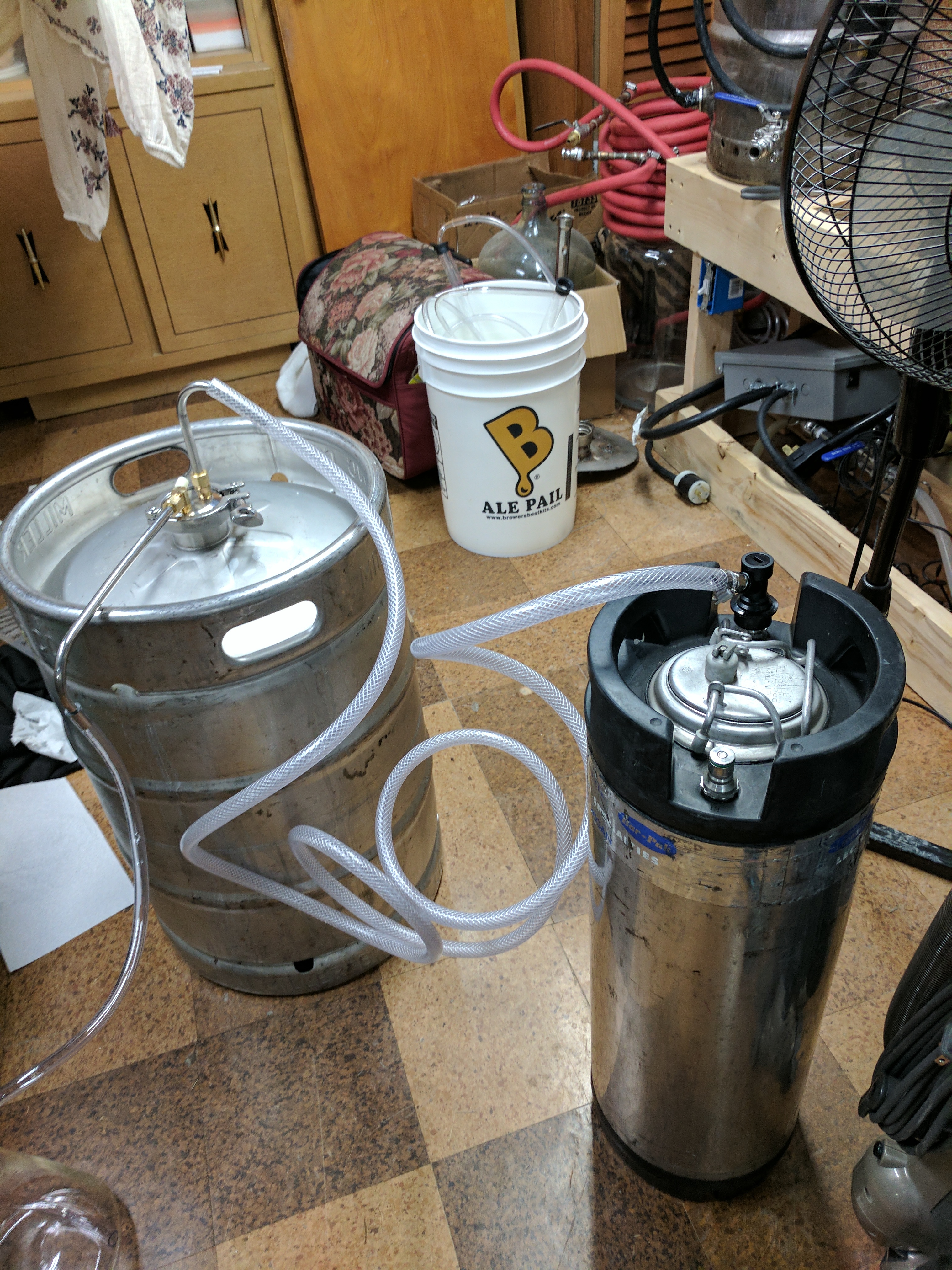

Hi all, I am working on a keg based fermenter. I made a jig to use a angle grinder to remove the stem from a new keg. I then measured the diference in diameter to depth of the remaining top surface. I came up with 11 degrees. I cut a piece of 6 3/4" diameter 316 stainless and turned up a cover that has a sealing surface to match the top surface of the keg. I will use a silicone gasket made from 1/16" thick silicon sheet stock to seal the cap to the keg. I need to machine holes into it to accommodate blow off and transfer. Pictures of where I am are below.

Sam

Sam