estricklin

Well-Known Member

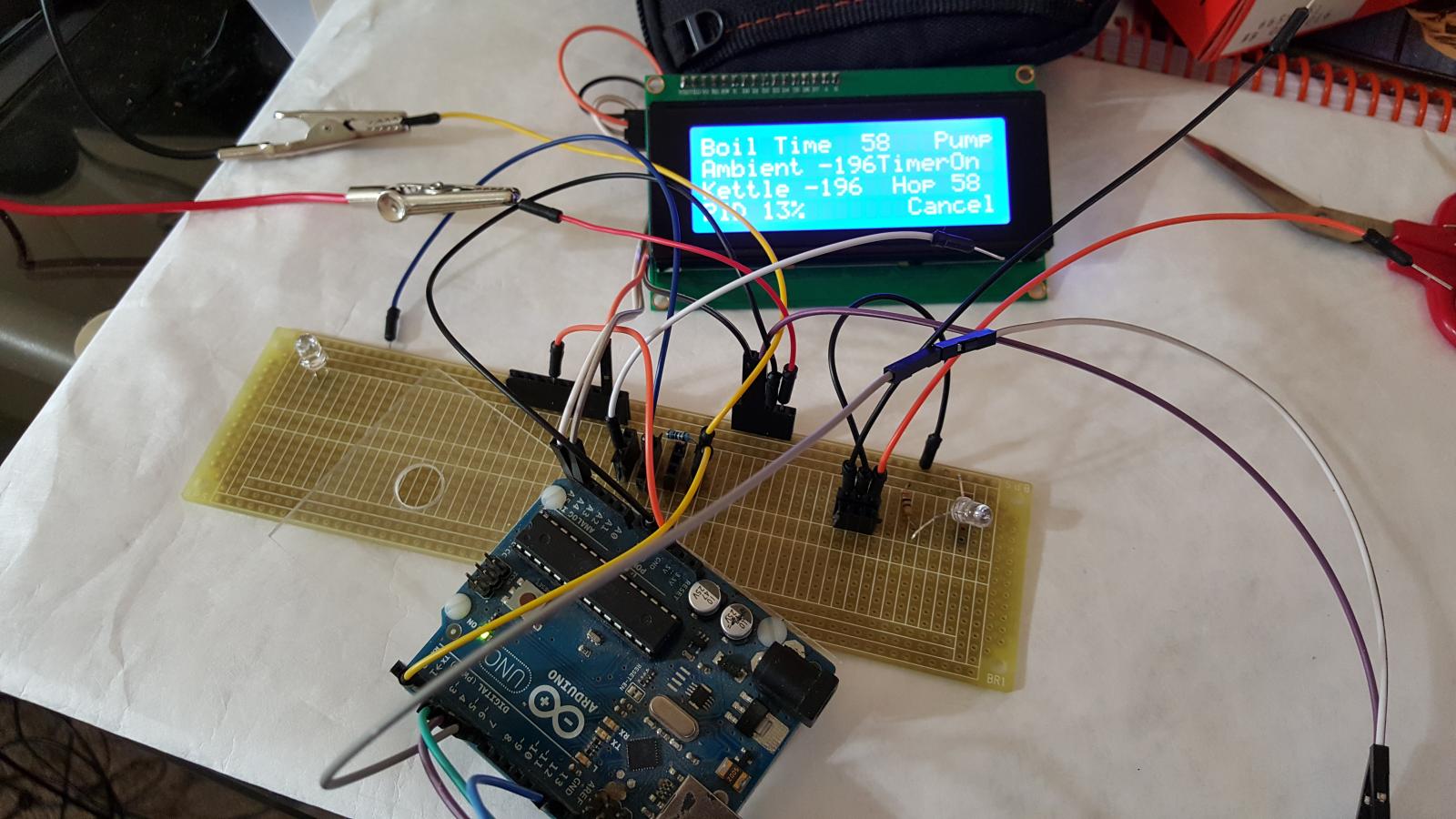

So I have a pretty rough start on the project thus far. I'm still missing several parts and I've got a lot of work ahead but I just wanted to go ahead and start a thread in case there are others who are trying to do something similar.

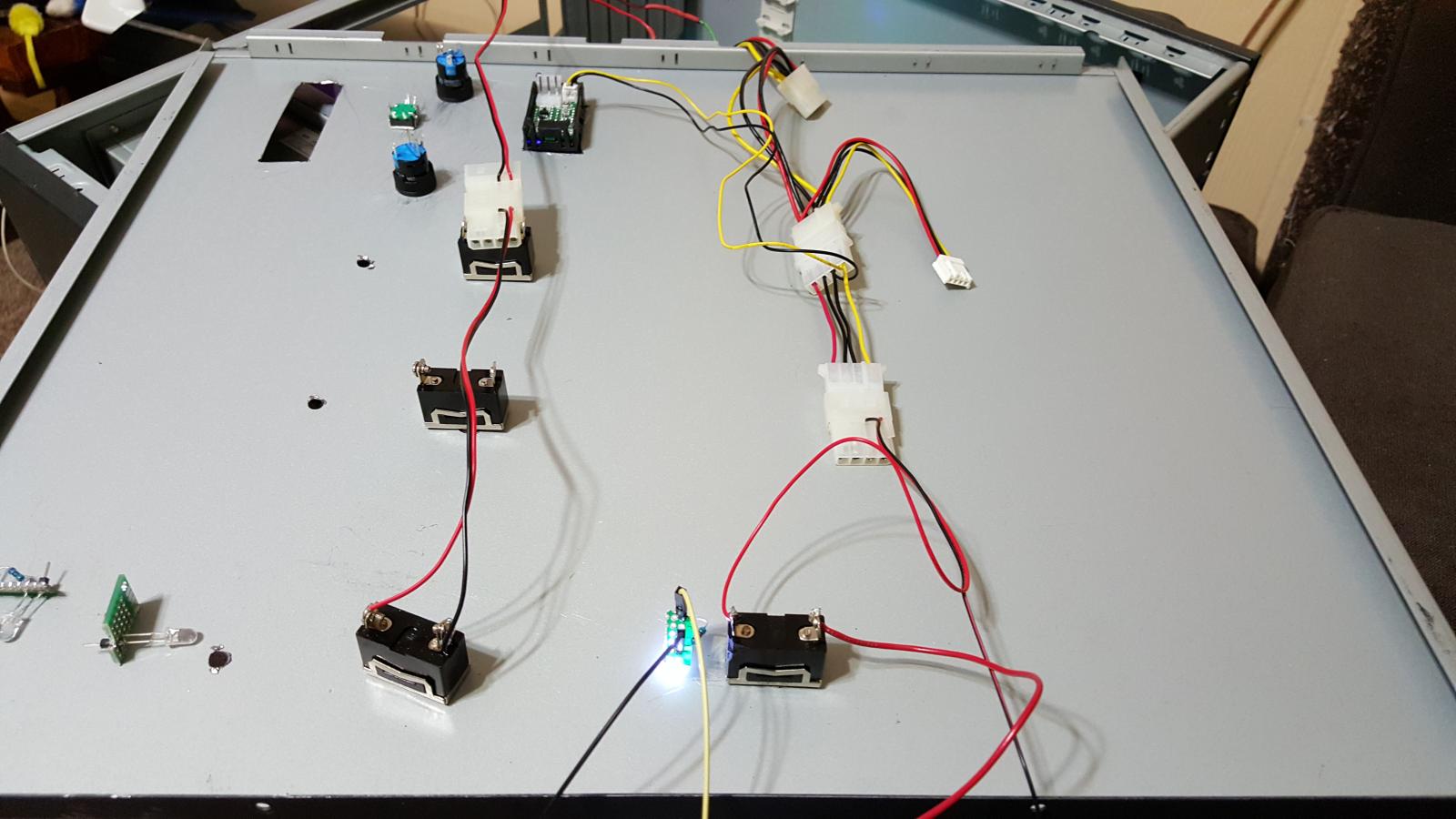

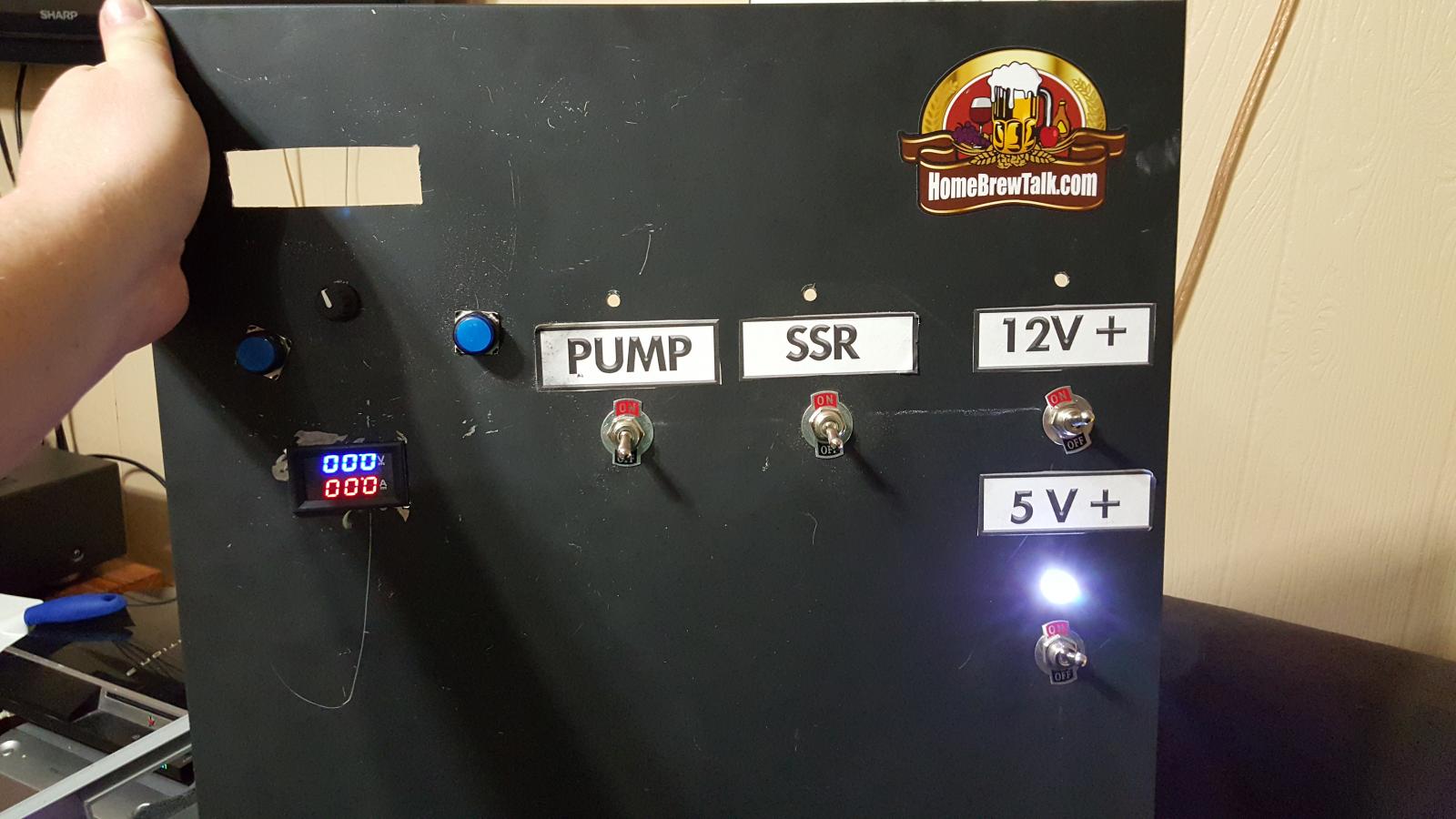

The Arduino will be mounted in an old computer case, I am using the PSU that was in it to power the Arduino, and my 12 volt wort pump. I am going to use some silicone and O rings to make the case as waterproof as possible, but it shouldn't matter much anyway since it's going to be 8-10 ft away from my kettle.

This will be for a BIAB system for now, but I will be upgrading it to a full 3 vessel later. I just wanted to get away from the propane and get this up and running as soon as I could; the extra 2 kettles I will need for a 3 vessel system can wait. I have a 25 gallon Concord with a Camco 5500 watt element for now.

One of the things I love about the Arduino is how easy it is to upgrade/change things. I am doing this project because I want an electric brewery, but I'm also doing it because I love to play with electronics and build things. I've already learned so much from this project, and it's not even over!

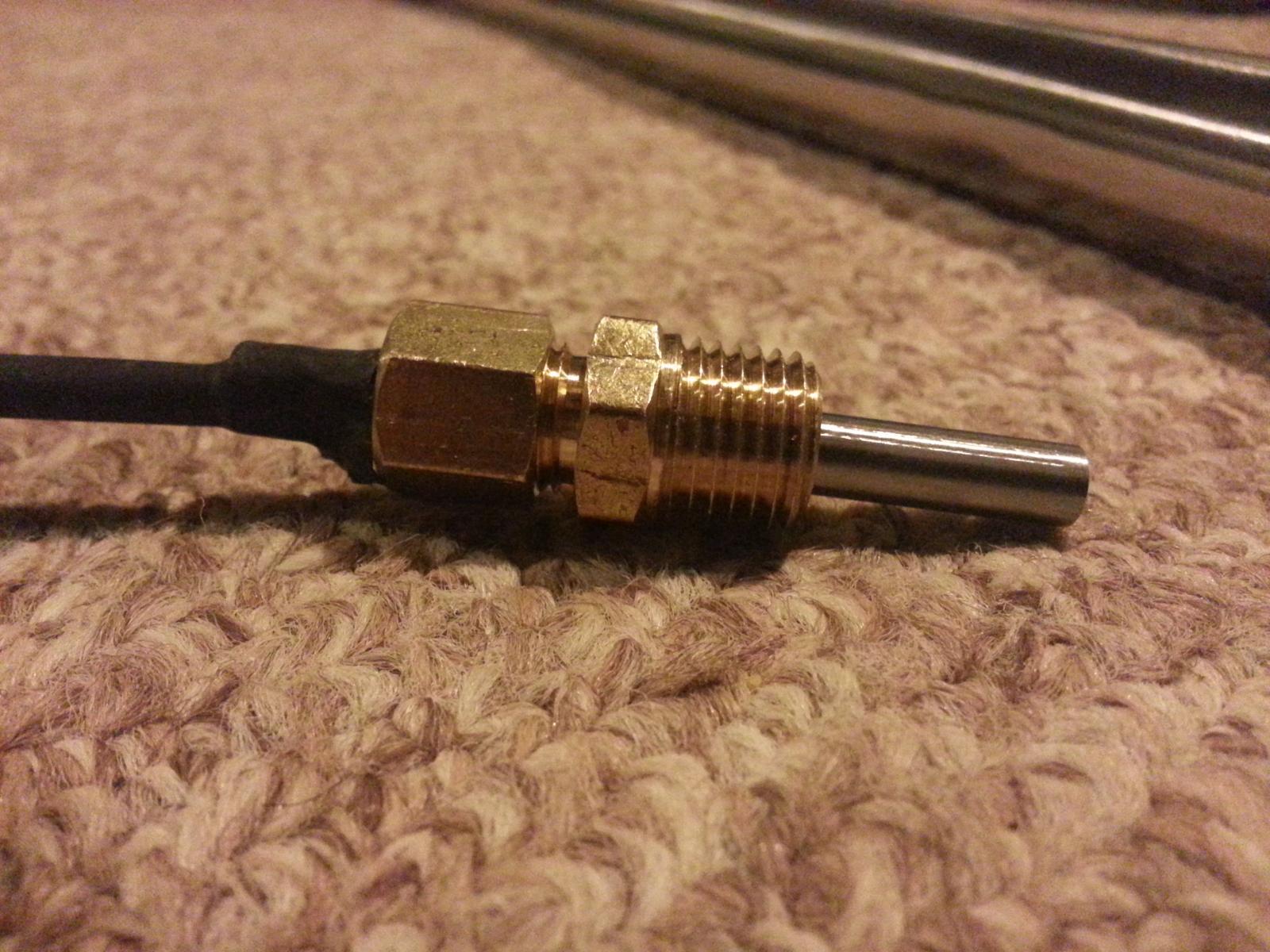

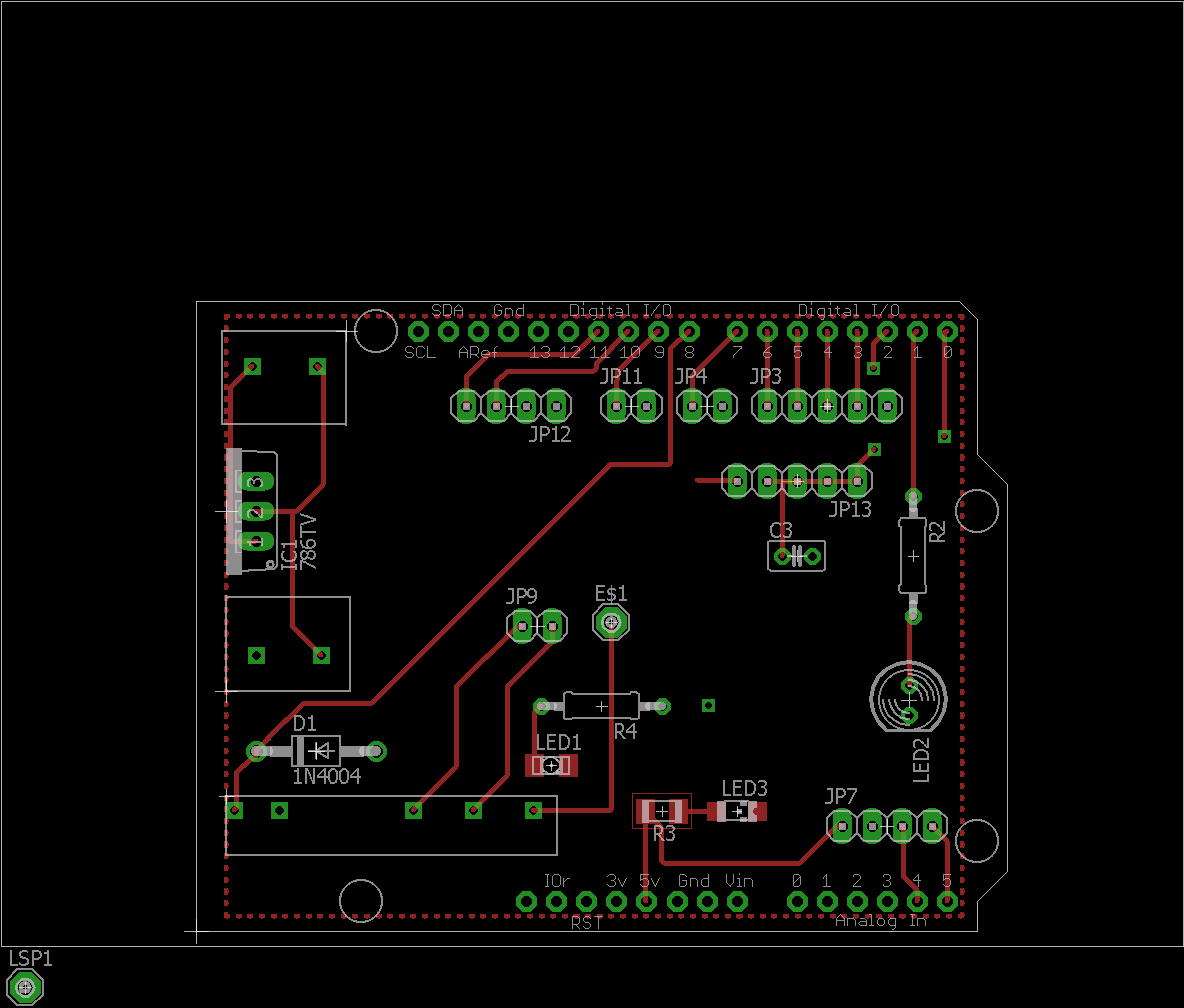

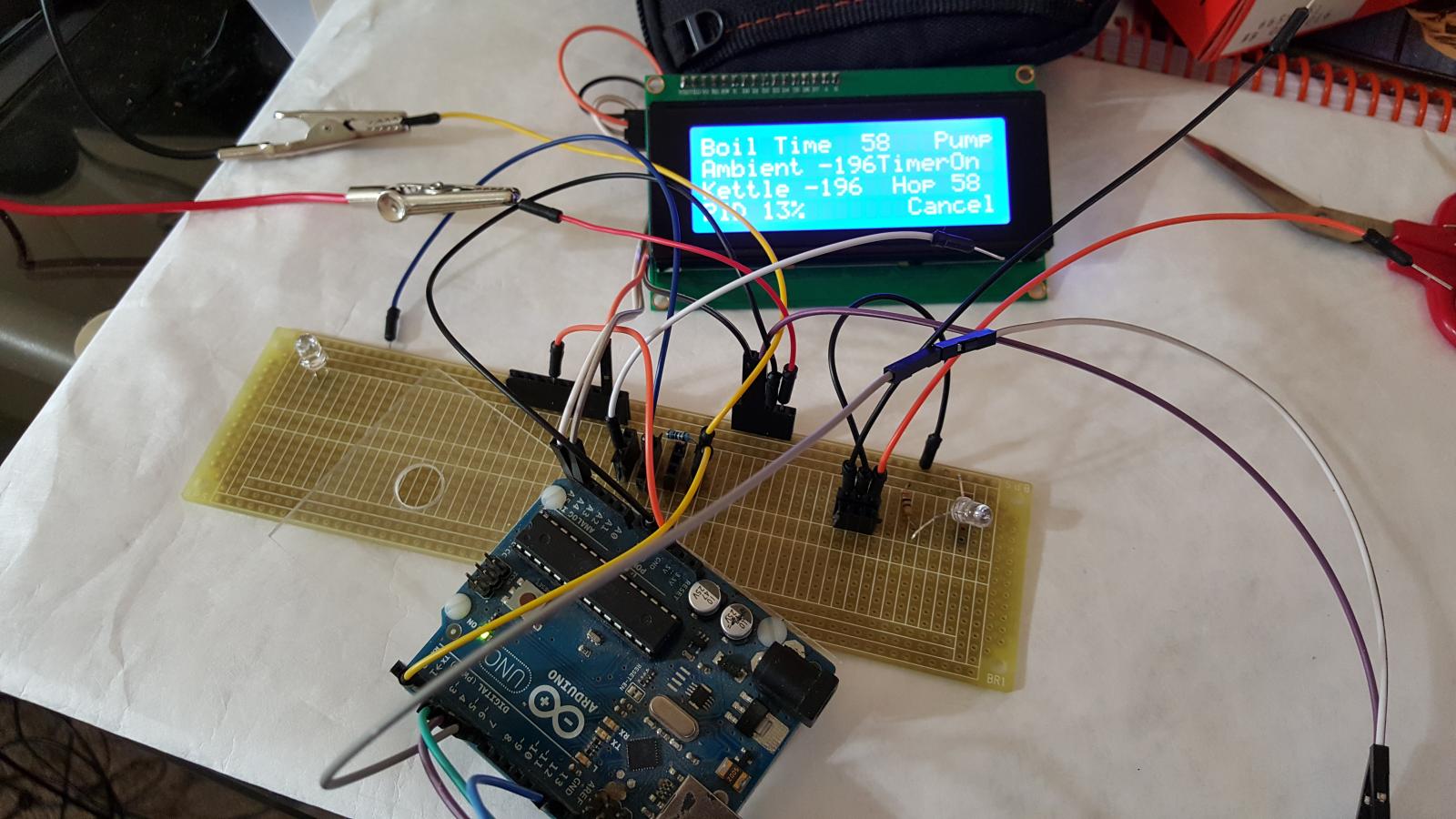

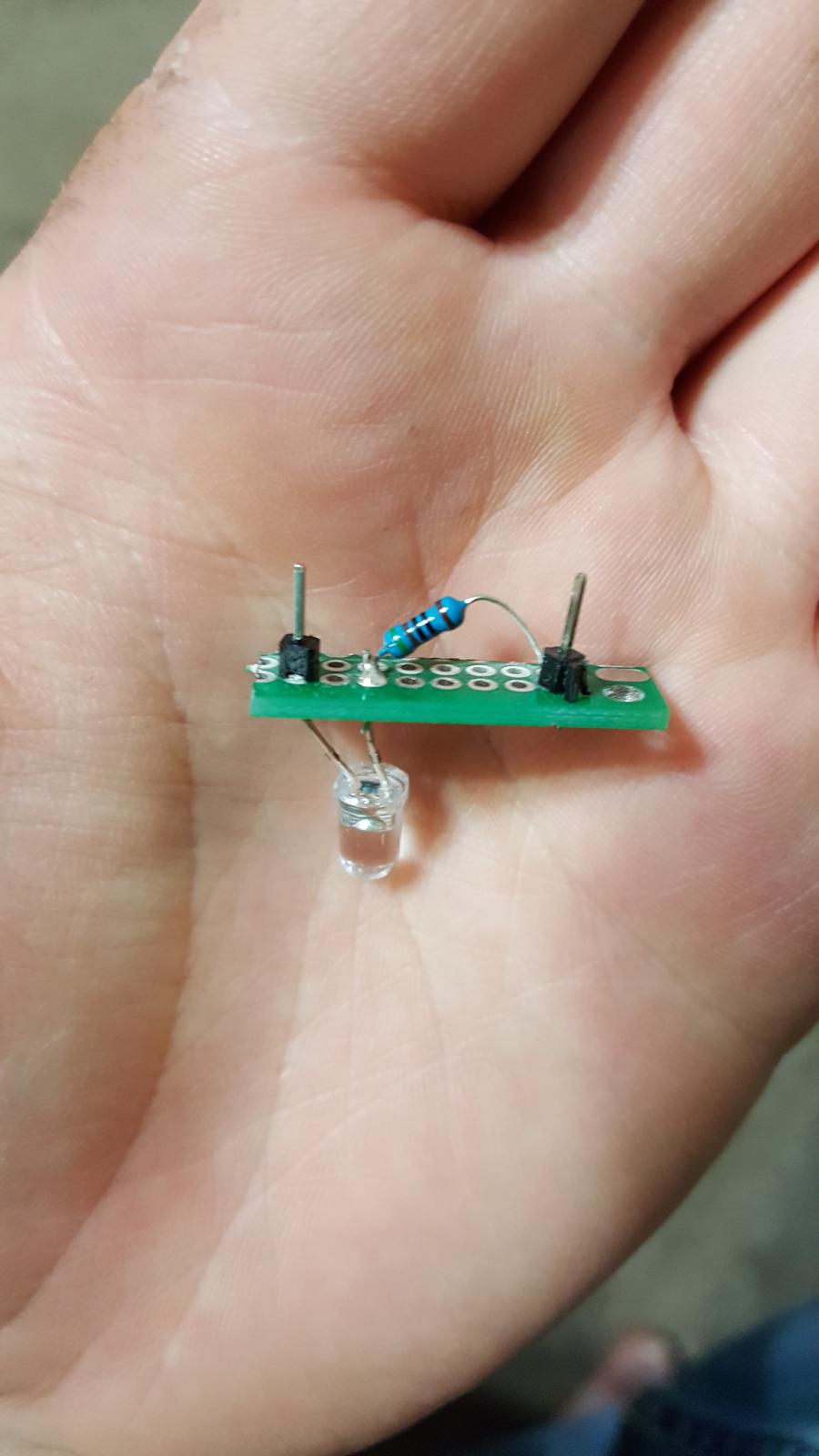

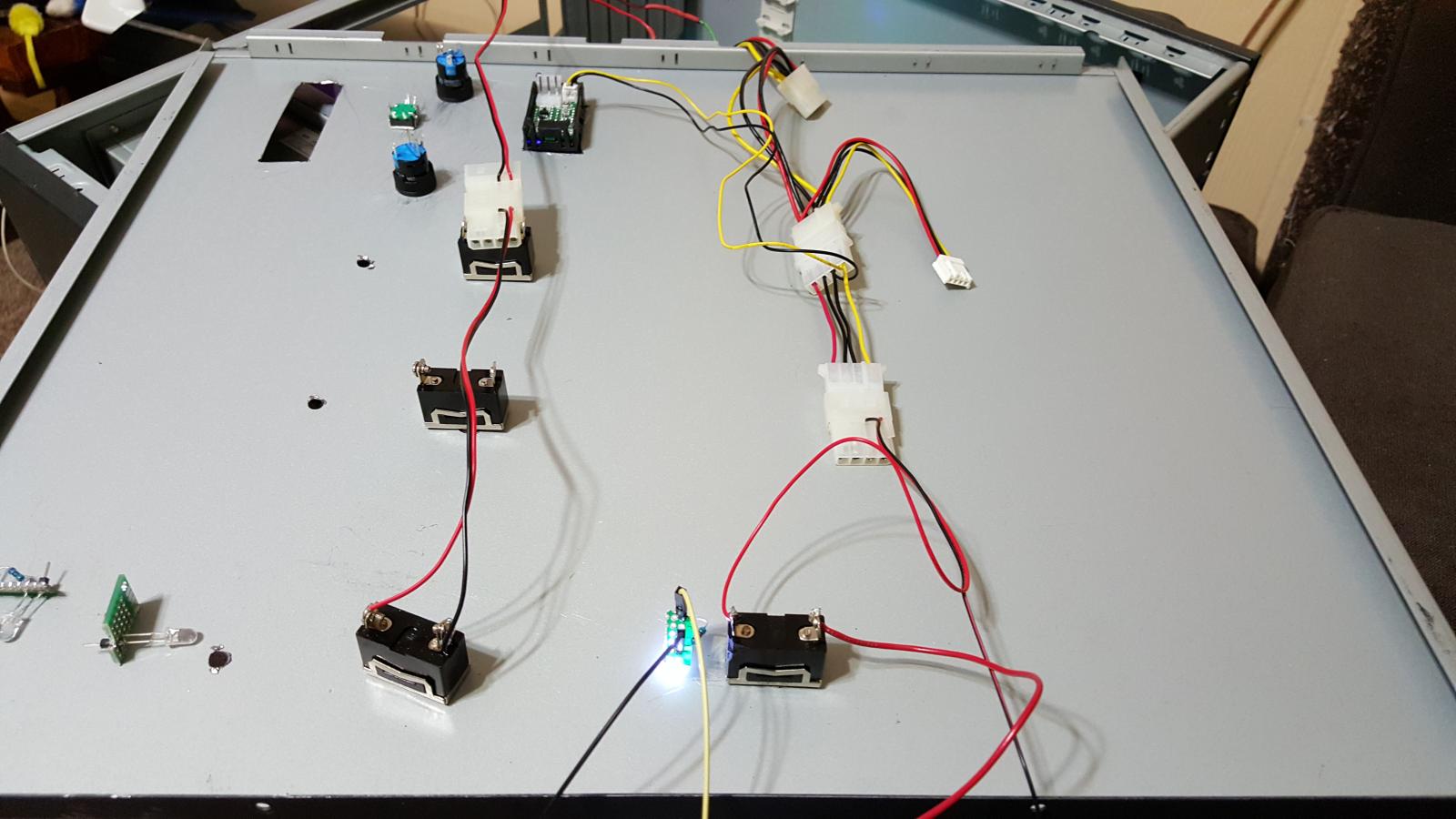

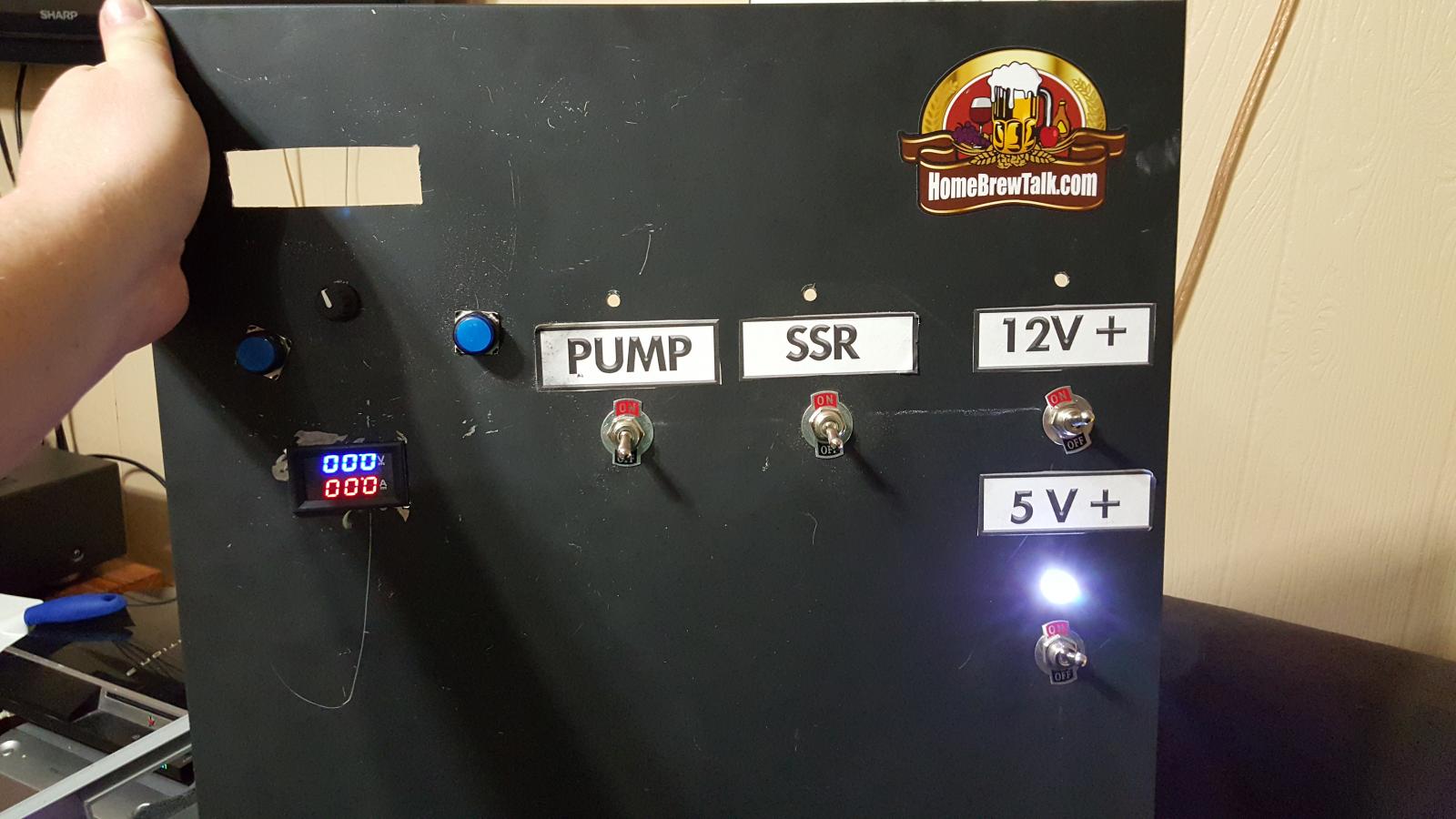

Here are a few pics, I will keep everyone updated as I go.

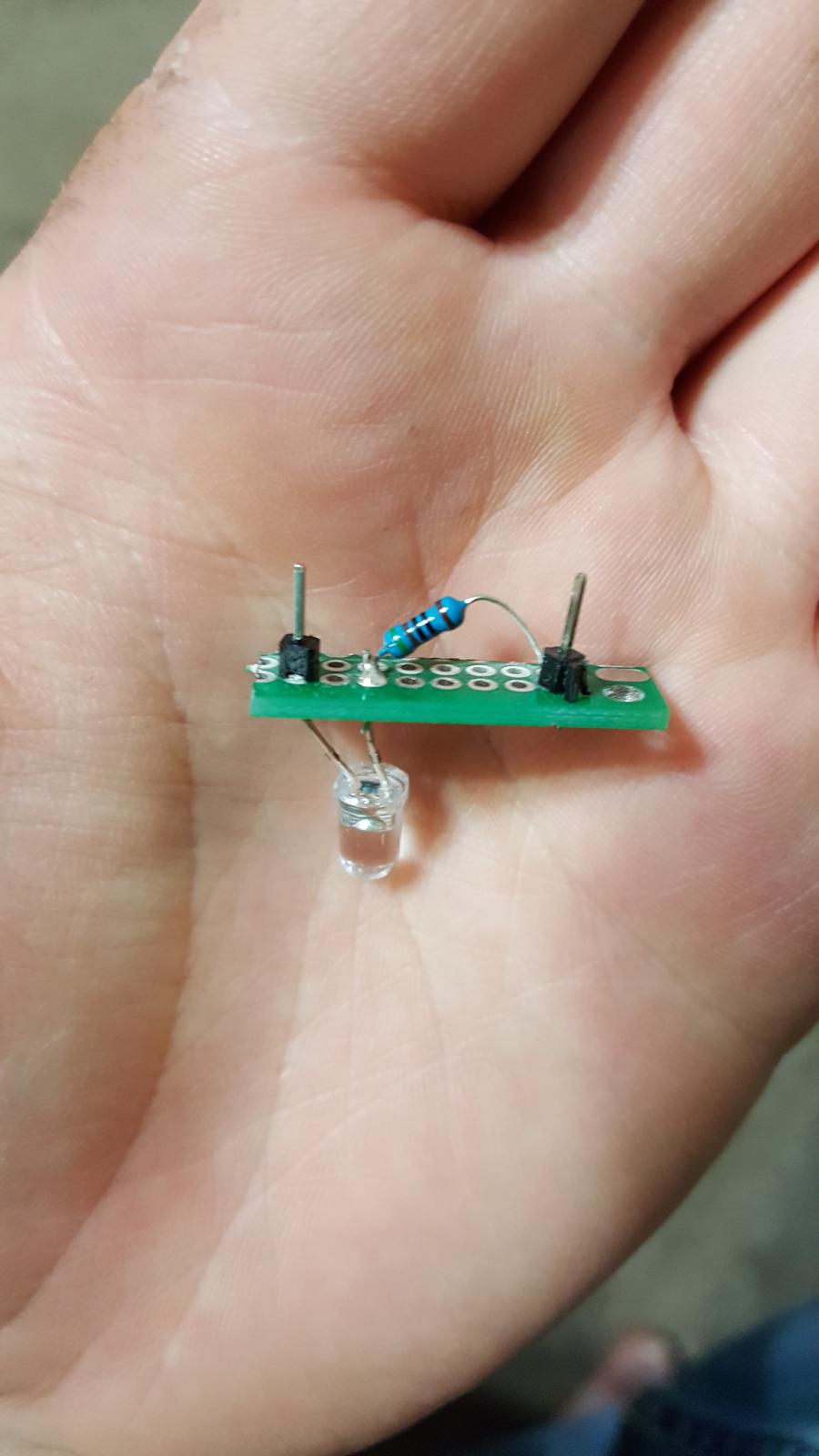

This is just some pics I snapped while I was doing some testing.

I will be taking some videos as well.

The Arduino will be mounted in an old computer case, I am using the PSU that was in it to power the Arduino, and my 12 volt wort pump. I am going to use some silicone and O rings to make the case as waterproof as possible, but it shouldn't matter much anyway since it's going to be 8-10 ft away from my kettle.

This will be for a BIAB system for now, but I will be upgrading it to a full 3 vessel later. I just wanted to get away from the propane and get this up and running as soon as I could; the extra 2 kettles I will need for a 3 vessel system can wait. I have a 25 gallon Concord with a Camco 5500 watt element for now.

One of the things I love about the Arduino is how easy it is to upgrade/change things. I am doing this project because I want an electric brewery, but I'm also doing it because I love to play with electronics and build things. I've already learned so much from this project, and it's not even over!

Here are a few pics, I will keep everyone updated as I go.

This is just some pics I snapped while I was doing some testing.

I will be taking some videos as well.