DutchessAles

Member

- Joined

- Dec 4, 2015

- Messages

- 5

- Reaction score

- 0

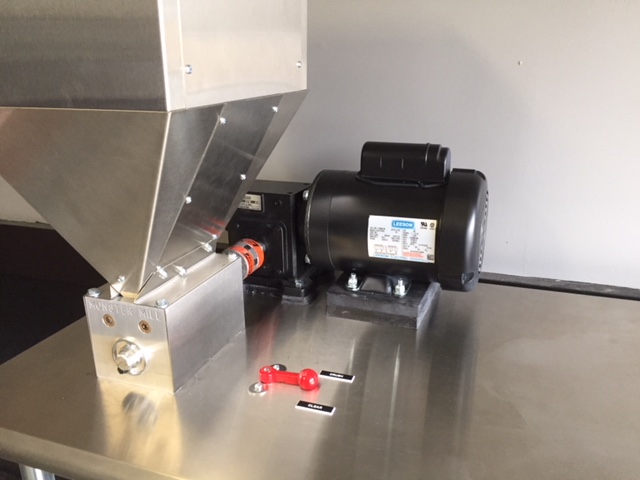

Motor will work but expensive. Check ebay should find something around $130. My reducer doesn't have a base and I haven't had any issues. When you attach it to the motor and mill its not going anywhere.

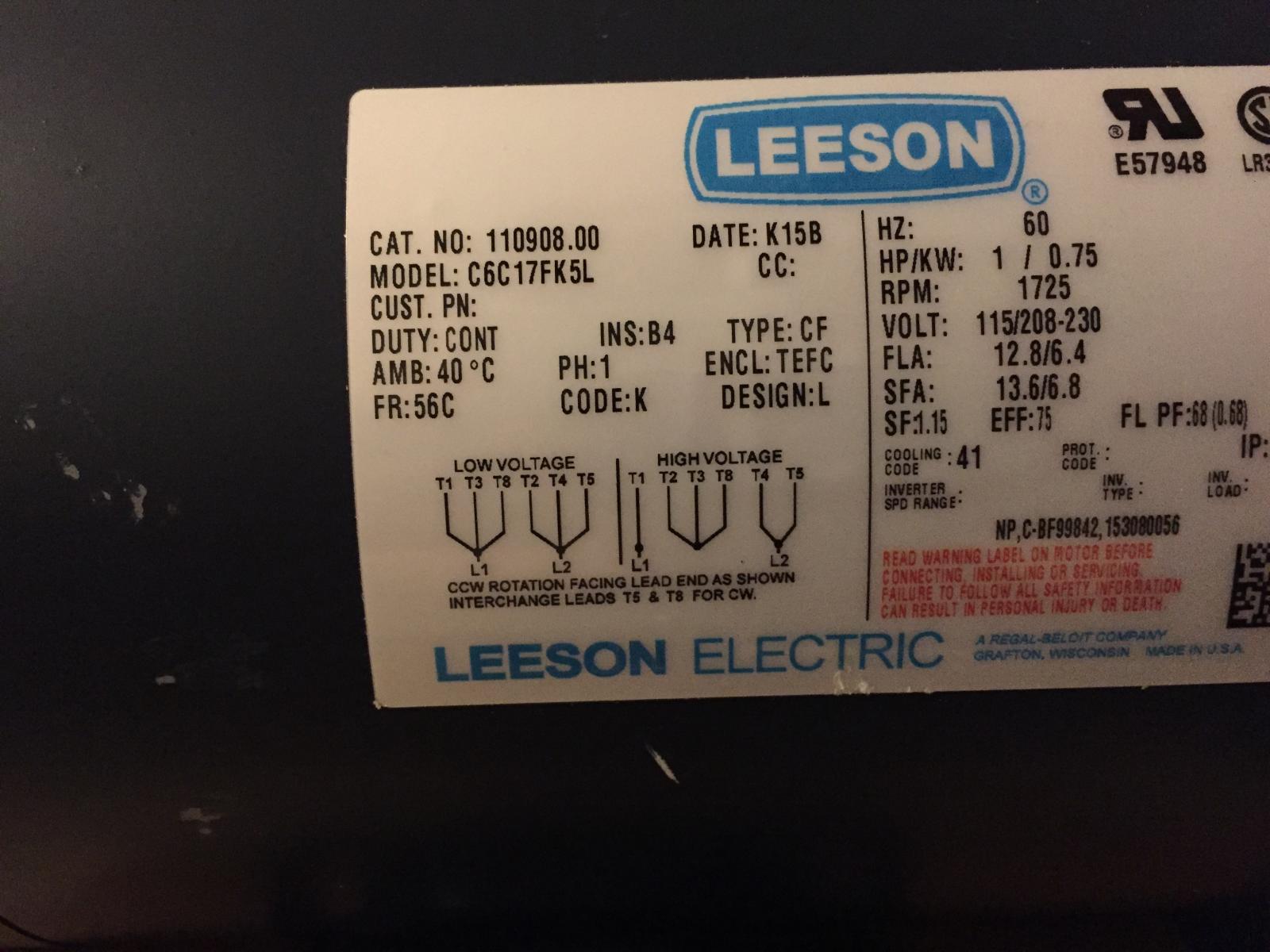

Nothing in the $130 ball park has a base and face mount as well as being Cap start and 56C.

Understood about the base. Cheers!