brinson44

Active Member

- Joined

- Mar 20, 2013

- Messages

- 38

- Reaction score

- 5

Hi folks,

I’m relatively new to the all grain world with only about six batches under my belt, and I’ve come to realize that I need some advice about achieving higher mash efficiency.

I recently found that MoreBeer tends to under crush their grains (or at least historically they have; couldn’t find any current data to confirm this) and I’m curious to know if any of you think that might be one of the reasons I’ve been missing my OG by quite a bit.

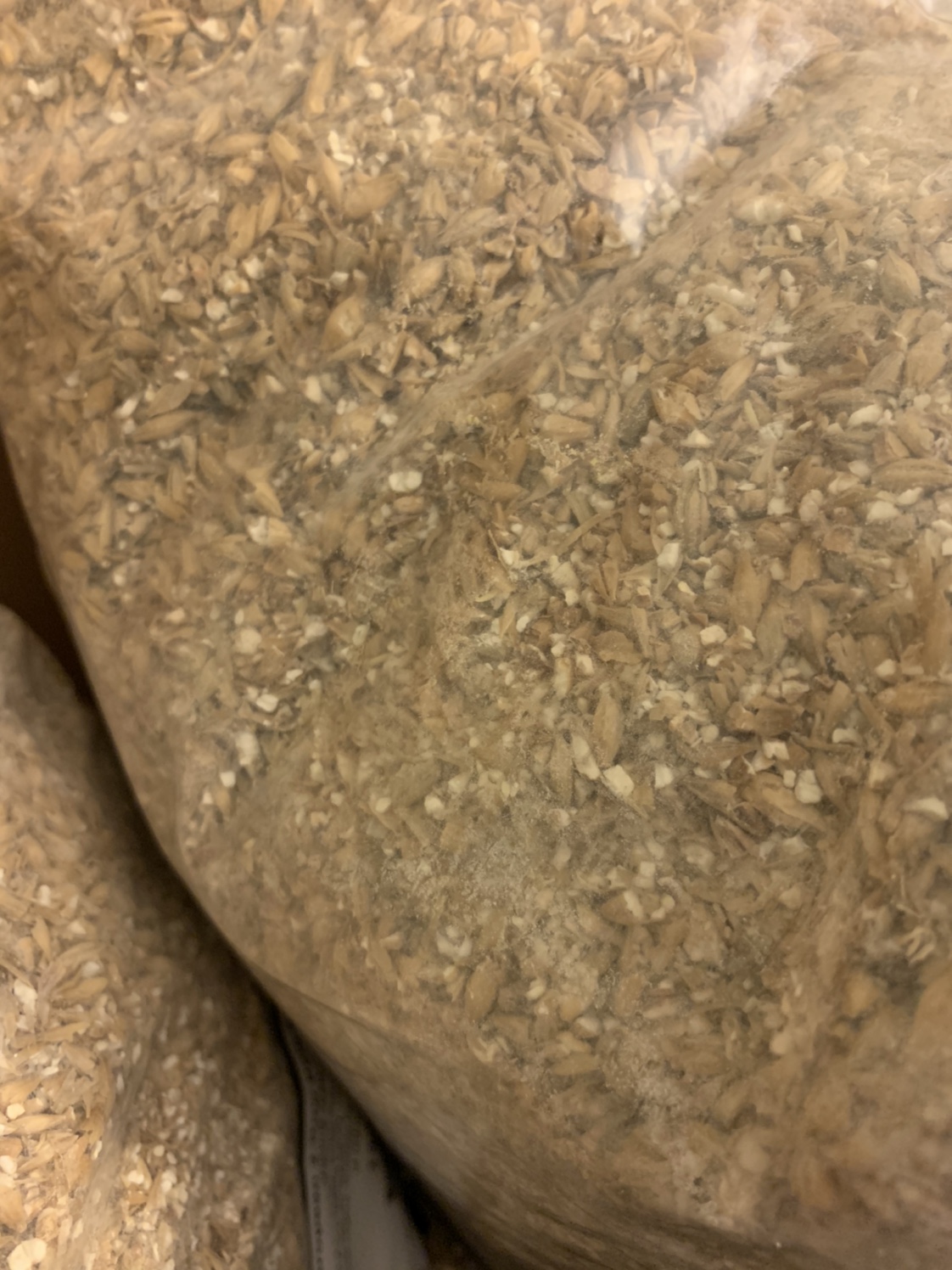

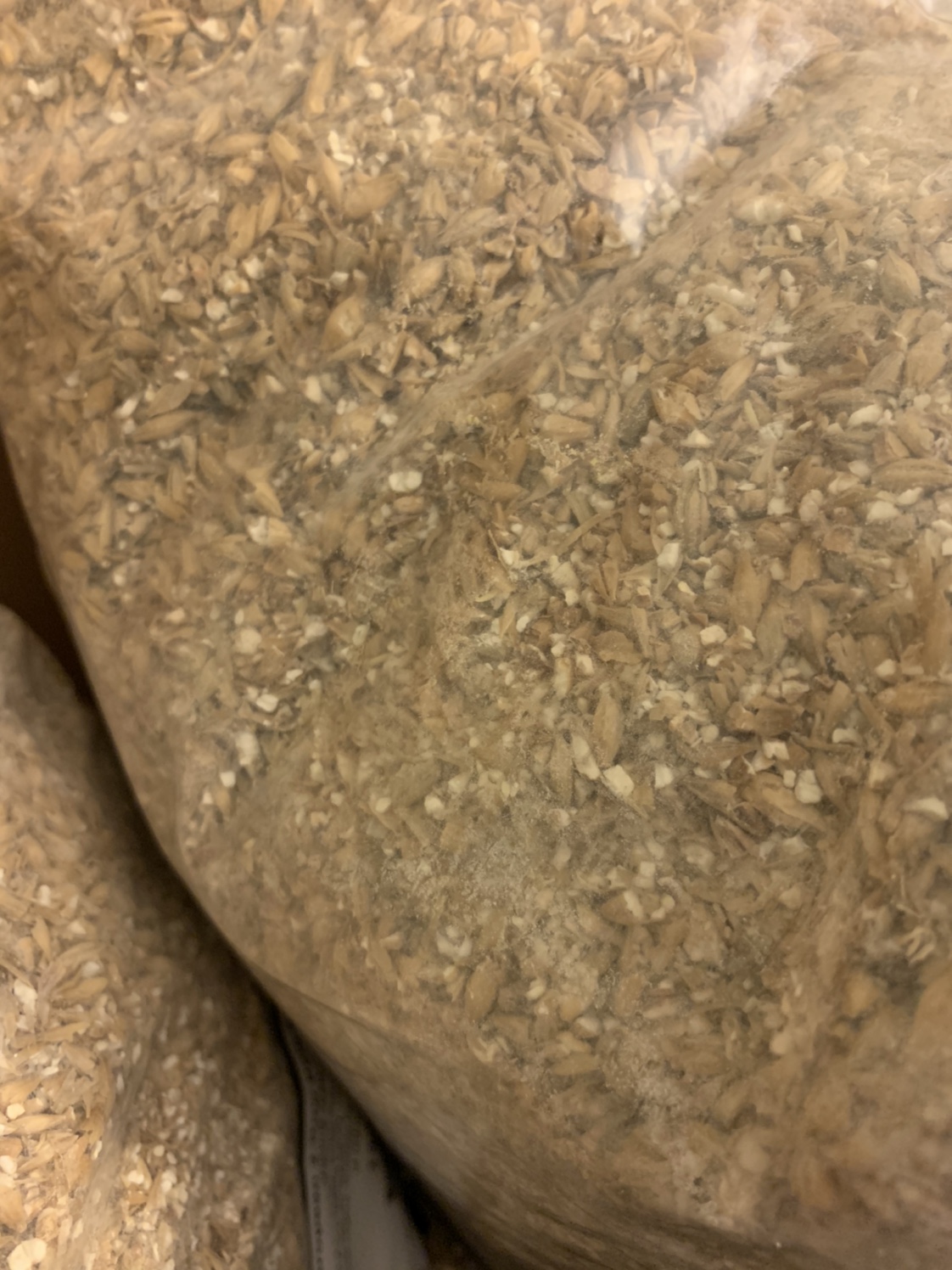

I don’t have a grain mill and I’ve only ever bought grain from MoreBeer so I don’t have any good visual cues to help me understand if the attached photo represents a “good crush”. I know it’s a long shot, but if anyone has any two cents to share about what I’m working with here and any suggestions on what I can do in the future (obviously I can buy a mill, but I’m mainly looking for help with this particular batch).

Thanks

I’m relatively new to the all grain world with only about six batches under my belt, and I’ve come to realize that I need some advice about achieving higher mash efficiency.

I recently found that MoreBeer tends to under crush their grains (or at least historically they have; couldn’t find any current data to confirm this) and I’m curious to know if any of you think that might be one of the reasons I’ve been missing my OG by quite a bit.

I don’t have a grain mill and I’ve only ever bought grain from MoreBeer so I don’t have any good visual cues to help me understand if the attached photo represents a “good crush”. I know it’s a long shot, but if anyone has any two cents to share about what I’m working with here and any suggestions on what I can do in the future (obviously I can buy a mill, but I’m mainly looking for help with this particular batch).

Thanks