<!DOCTYPE html>

<html>

<head>

<meta http-equiv="Content-Type" content="text/html;charset=utf-8">

<link href="/images/favicon.ico" rel="icon" type="image/x-icon">

<link rel=StyleSheet href="css/styles.css" type="text/css">

<title>Kämpferstrahl Brew Monitor</title>

<script type="application/javascript" src="./js/gauge.js"></script>

<script type="application/javascript" src="./js/light.js"></script>

<script type="application/javascript">

// global variables to hold data from Ajax requests

var steamPress = 0;

var steamTemp = 0;

var mashTemp = 0;

var spargeTemp = 0;

var boilTemp = 0;

var mashVol = 0;

var boilVol = 0;

var lightTest = false;

var steamElement = 0;

// Ajax request for xml data generated by Arduino

function ajaxUpdateValues() {

var httpRequest;

var xmlDoc;

// get the xml document via Ajax/http

httpRequest = new XMLHttpRequest();

httpRequest.onreadystatechange=function() {

if(httpRequest.readyState == 4) {

steamPress = Number(httpRequest.responseText);

}

}

httpRequest.open("GET","./xml/brewhut.xml",false);

httpRequest.send(null);

xmlDoc=httpRequest.responseXML;

// update the global variables by parsing the xml document

steamPress=Number(xmlDoc.getElementsByTagName("steamPress")[0].childNodes[0].nodeValue);

steamTemp=Number(xmlDoc.getElementsByTagName("steamTemp")[0].childNodes[0].nodeValue);

spargeTemp=Number(xmlDoc.getElementsByTagName("spargeTemp")[0].childNodes[0].nodeValue);

mashTemp=Number(xmlDoc.getElementsByTagName("mashTemp")[0].childNodes[0].nodeValue);

boilTemp=Number(xmlDoc.getElementsByTagName("boilTemp")[0].childNodes[0].nodeValue);

mashVol=Number(xmlDoc.getElementsByTagName("mashVol")[0].childNodes[0].nodeValue);

boilVol=Number(xmlDoc.getElementsByTagName("boilVol")[0].childNodes[0].nodeValue);

steamElement=Number(xmlDoc.getElementsByTagName("steamElement")[0].childNodes[0].nodeValue);

}

// force the webcam image to reload by appending time data

function updateImage() {

var img = document.getElementById("webcam");

var now = new Date();

img.src="images/cam.jpg"+ "?" + now.getTime();

}

// this function calls the Ajax update and draws the canvas elements

// it is to be executed repeatedly through the use of the setInterval method

function update() {

// update Arduino data

ajaxUpdateValues();

// draw gauges

var canvas = document.getElementById("steamPress");

var ctx = canvas.getContext("2d");

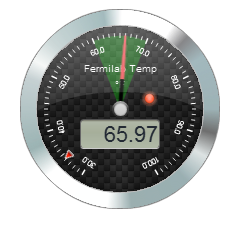

drawGauge(ctx, 0, 20, 0.25, 1, "Steam Pressure", "psi", steamPress);

canvas = document.getElementById("steamTemp");

ctx = canvas.getContext("2d");

if (steamTemp < 0) {

drawGauge(ctx, 60, 260, 5, 10, "Steam Temp", "Error", 0);

} else {

drawGauge(ctx, 60, 260, 5, 10, "Steam Temp", "Deg F", steamTemp);

}

canvas = document.getElementById("mashTemp");

ctx = canvas.getContext("2d");

if (mashTemp < 0) {

drawGauge(ctx, 20, 220, 5, 10, "Mash Temp", "Error", 0);

} else {

drawGauge(ctx, 20, 220, 5, 10, "Mash Temp", "Deg F", mashTemp);

}

canvas = document.getElementById("spargeTemp");

ctx = canvas.getContext("2d");

if (spargeTemp < 0) {

drawGauge(ctx, 20, 220, 5, 10, "Sparge Temp", "Error", 0);

} else {

drawGauge(ctx, 20, 220, 5, 10, "Sparge Temp", "Deg F", spargeTemp);

}

canvas = document.getElementById("boilTemp");

ctx = canvas.getContext("2d");

if (boilTemp < 0) {

drawGauge(ctx, 20, 220, 5, 10, "Boil Temp", "Error", 0);

} else {

drawGauge(ctx, 20, 220, 5, 10, "Boil Temp", "Deg F", boilTemp);

}

canvas = document.getElementById("mashVol");

ctx = canvas.getContext("2d");

if (mashVol < 0) {

drawGauge(ctx, 0, 24, 0.5, 1, "Mash Volume", "Error", 0);

} else {

drawGauge(ctx, 0, 24, 0.5, 1, "Mash Volume", "Gal", mashVol);

}

canvas = document.getElementById("boilVol");

ctx = canvas.getContext("2d");

if (boilVol < 0) {

drawGauge(ctx, 0, 24, 0.5, 1, "Boil Volume", "Error", 0);

} else {

drawGauge(ctx, 0, 24, 0.5, 1, "Boil Volume", "Gal", boilVol);

}

canvas = document.getElementById("steamElement");

ctx = canvas.getContext("2d");

drawGauge(ctx, 0, 100, 2, 10, "Heating Element", "%", steamElement);

}

// make the script execute at a set interval (in milliseconds)

function init() {

setInterval("update();", 500);

setInterval("updateImage();", 3000);

}

</script>

</head>

<body onload="init();">

<div>

<table style="margin-left:auto;margin-right:auto;">

<tr>

<td>

<table style="margin-left:auto;margin-right:auto;">

<tr>

<td>

<canvas id="steamPress" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

<td>

<canvas id="mashVol" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

<td>

<canvas id="boilVol" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

</tr>

<tr>

<td>

<canvas id="steamTemp" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

<td>

<canvas id="mashTemp" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

<td>

<canvas id="boilTemp" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

</tr>

<tr>

<td></td>

<td>

<canvas id="spargeTemp" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

<td>

<canvas id="steamElement" width="180" height="200">

This page is incompatible with your browser.

</canvas>

</td>

</tr>

</table>

</td>

<td style="vertical-align:text-top;">

<img id="webcam" height="400" src="images/cam.jpg">

</td>

</tr>

</table>

</div>

<div style="text-align:center;">

<span style="font-family: PHANTOM STENCIL; color: #222222; font-size: 69pt;">Kampferstrahl</span>

<h4>Version 0.2.3, 7 Feb 10 --- <a href="http://twitter.com/kampferstrahl">Twitter</a></h4>

</div>

<div>

<br><br><br><br>

<p><a href="http://brew-hut">Back to server homepage</a>

<p style="font-size:125%">

Arduino's output must be dumped to /var/www/xml/brewhut.xml in real time for this page to be useful.<br>

A script called brewhut runs `head -n 12 /dev/ttyUSB0 > /var/www/xml/brewhut.xml` about every 250 ms.<br>

Whenever a sketch is uploaded to Arduino, running `screen /dev/ttyUSB0 115200` will recapture the serial port for terminal use.<br>

</div>

</body>

</html>