I do continuous re-circulation eBIAB in a six gallon pot. I typically mash with about 4.2 gallons of water, and then move the bag to a strainer in a large bowl where I do a pour-over sparge to get my volume back up. When all is said and done, I usually wind up with about 3.5 gallons to my fermenter due to boil and equipment loss. My gravity is usually higher than planned as well, so I top off with RO water (I salt it first) and get to the 4 to 4.25 gallon range in the fermenter, where trub and other losses follow.

I know what I want to do, but I am having trouble wrapping my brain about how to calculate it. I want to do all grain and I want an OG of 1.065. 1.070 would be even better. Between sparging and simply adding more water post-boil (i.e., partial boil) I want five gallons in the fermenter. Five gallons post-trub loss would be even better.

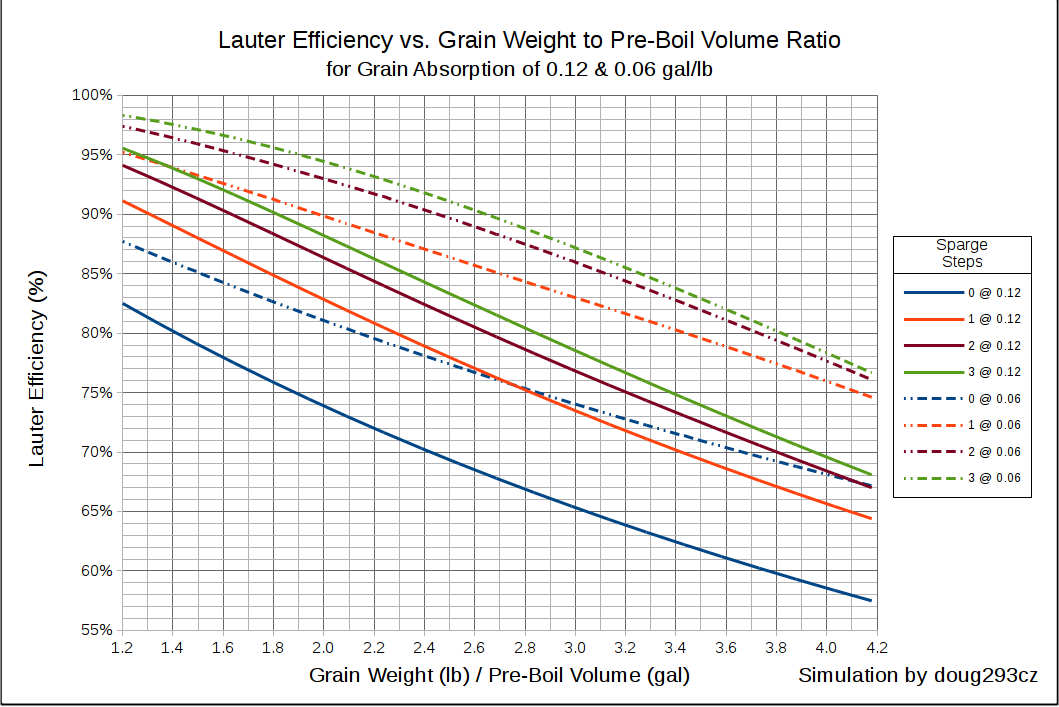

Is this possible? There comes a point where adding more grain to my six gallon pot will lead to lower and lower efficiencies, but I do not know how to determine where that point is. How much grain is too much grain in a six gallon pot?

I know what I want to do, but I am having trouble wrapping my brain about how to calculate it. I want to do all grain and I want an OG of 1.065. 1.070 would be even better. Between sparging and simply adding more water post-boil (i.e., partial boil) I want five gallons in the fermenter. Five gallons post-trub loss would be even better.

Is this possible? There comes a point where adding more grain to my six gallon pot will lead to lower and lower efficiencies, but I do not know how to determine where that point is. How much grain is too much grain in a six gallon pot?