Ok I have been reading a bit here and there when the topic of LoDo comes up, which it does quite often it seems. Now most of these conversations come with a certain amount of drama that makes me a little stand offish about participating. Now that Yooper has started this thread I am going to get a little more involved.

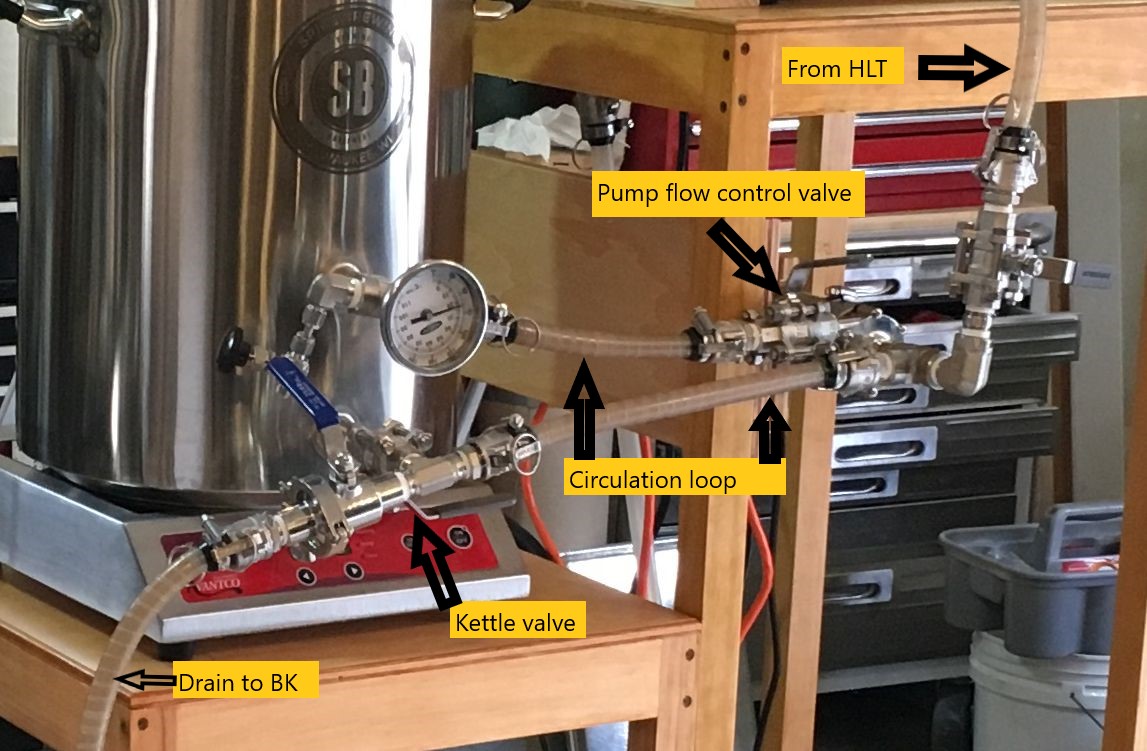

My recirculating BIAB system as it sits is set up to under let the mash water into the mash tun from a 10 gallon cooler. I preheat the water in the mash tun and then pump it to the cooler, load the grains in the bag and pump the water back under letting the grain in the mash tun. I have thought about boiling the water first per the LoDo technique and adding a mash cap. I currently use a Loc Line ring for recirculating.

So, I want to see what everyone is using for a mash cap and re-circulation.

My recirculating BIAB system as it sits is set up to under let the mash water into the mash tun from a 10 gallon cooler. I preheat the water in the mash tun and then pump it to the cooler, load the grains in the bag and pump the water back under letting the grain in the mash tun. I have thought about boiling the water first per the LoDo technique and adding a mash cap. I currently use a Loc Line ring for recirculating.

So, I want to see what everyone is using for a mash cap and re-circulation.