This is an article of mine that appeared on HBT 6-26-2015 and seemed to be well received and be of benefit to some. I thought I would post it in this, the fermentation & yeast forum also, in the hope it be more easily accessible for future reference.

A lab-grade borosilicate flask

These are readily available from an array of reputable homebrew and laboratory supply stores and come in a variety of sizes. From personal experience (and much to my chagrin) owning a trifecta of flasks in 1, 2, and 5 liter sizes, I would advise against buying one smaller than 2 liters.

A stir-bar (optional)

Using a stir plate is highly recommended. Constantly stirring the starter optimizes oxygen absorption into the wort and keeps the yeast in suspension. The result is a more rapid completion of the starter and greater yeast growth-rates.

A non-airtight stopper

During fermentation of the starter, a free in-flow of air while at the same time preventing ingress of airborne particulate is desirable. This allows an oxygen-rich, sanitary environment to be maintained inside the flask. A sanitized foam stopper or aluminum-foil will serve this purpose effectively. Airlocks are contra-indicated.

A weighing scales with gram resolution

A starter gravity approximating 1.037 is desirable. To achieve this 1g of dry malt extract is needed for every 10ml of the planned starter size.

A heat source capable of bringing the starter volume to a boil.

I imagine most folks will use their kitchen stove when making a starter. A gas stove is not required, but is arguably preferable, as any required adjustments to the intensity of the heat can be made with immediate effect.

Dry malt extract (DME)

This is an incredibly hydrophilic fine powder. It is imperative to keep it stored in a sealed container or zip-lock bag and to use it in the absence of water vapor to prevent a sticky mess from forming. Albeit an extreme example, the less than desirable results of trying to add DME to already heating water can be seen in this thread.

Water

Assuming the water is potable, tap-water is all thats required. There is no need to consider mineral or pH adjustments for a starter.

Yeast Nutrient (optional)

Yeast nutrient can be added in small amounts if there are concerns about the viability or health of the source-yeast.

Fermcap® S

This product is an emulsion of the active ingredient, dimethylpolysiloxane. This prevents foam formation by reducing surface tension. It has long been approved by the FDA and WHO for human consumption.

A thorough outline of the science supporting its safety was compiled in 1975 by The World Health Organization's International Program on Chemical Safety. In addition to being a safe and effective anti-flatulence medication, frequently given to infants, the active ingredient in Fermcap® S can be found in many foods and beverages. The effective medicinal dosages are orders of magnitude higher than the amounts used in homebrewing.

To put it bluntly, you can ingest lots of dimethylpolysiloxane to stop you from farting so much. It goes in one end and out the other unchanged. No worries.

Making the starter

1. Calculate the desired starter size and gravity

There are plenty of incredibly useful and free online tools with which to calculate starter size needed for any given batch of homebrew. I am a fan of Homebrewdad's yeast starter calculator as I like to overbuild and harvest yeast for future brews directly from the starter. The projected size of a starter will vary depending on a multitude of factors including starting gravity and volume of the batch, the planned pitch rate, and the projected viability of the yeast being used.

2. Place the flask on the weighing-scales and zero it out

Place the required weight of DME into the flask and subsequently add cool tap-water to reach the desired volume. In order to target the planned specific gravity it is important to add the DME first and then the water. If this is done in the opposite manner, i.e. water first, DME second, the volume will be larger than planned and the gravity reduced accordingly.

3. Carefully add the stir-bar

Tilt the flask and insert the bar, allowing it to gently slide down the flask-wall. I have never broken a flask, but imagine that repeatedly dropping a stir bar into one, could, at least in theory, potentially weaken the glass. Perhaps not.

4. If using yeast nutrient in the starter, now is the time to add it

Adding a stir-bar or powdered yeast nutrient to near-boiling or boiling wort is likely to cause a sudden and violent boil-over to occur. The result is a sticky mess and a potentially painful experience. DO NOT ADD ANYTHING TO THE HEATING OR BOILING WORT.

5. Add one drop of Fermcap® S to the starter

This is an incredibly useful product and is in my view indispensable if making starters in an erlenmeyer flask. One drop weighs approximately 0.05g of which only a portion is dimethylpolysiloxane.

6. Heat the starter wort

Heat the wort while occasionally swirling the flask to completely mix the DME and water.

7. Bring the starter to a boil and boil it for the desired time

It would seem there is no definitive duration for which this needs to be done. In order to render microbe-laden water water safe to drink, the United States Center for Disease Control advocates boiling for one minute. Three minutes is recommended above an altitude of 6,500 feet. Boiling for one minute will sanitize water killing the vast majority of water-borne pathogens. Is this boil duration applicable to sanitizing a starter wort and flask? Ill let the reader decide. I boil my starter for 10 minutes but have no good basis for why. I just let it boil as I do other things.

8. Cool the starter

This can be easily and safely done by taking the flask off the heat, placing a sanitized foam stopper or aluminum-foil and immediately immersing the flask in cold water. A lab-grade borosilicate flask is designed with much greater temperature swings in mind.

9. Add Yeast to the starter wort

Once cooled, remove the stopper and pitch the yeast. Star san or any no-rinse sanitizer can be used to sanitize the outside of the yeast pack/vial or jar prior to pitching. Replace the sanitized sponge stopper once yeast has been added to the starter.

10. Allow the starter to ferment to completion

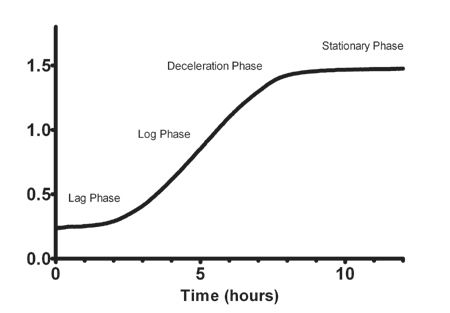

I usually allow 48 hours for this to occur. If using a stir-plate, this is in all likelihood far more time than is needed.

11. Chill the starter

I routinely chill a starter in the refrigerator for 3-4 days prior to using it. This allows ample time for the majority of yeast strains to flocculate and form a dense layer of yeast in the bottom of the flask. This is particularly important with large starters where adding excessive volumes of spent starter-wort could have an impact on the characteristics of the final beer.

12. Decant wort and pitch yeast

On brew-day, decant the spent wort and pitch the yeast. To prevent stressing the yeast it is desirable to have the yeast and wort at similar temperatures. The wort is cooled to a temperature slightly below that at which initial fermentation will occur and the yeast removed from the refrigerator a few hours prior to pitching with this goal in mind. Differing opinions on pitching temperature exist and I am certainly no authority on the topic. This is the method I favor.

Making a starter in an Erlenmeyer flask is simple, hassle free and can be completed while doing other things. I usually make my starters while cooking dinner on Monday evenings in preparation for a weekend brew. By eliminating the risk of boil-overs, the process becomes entirely uneventful, requiring minimal oversight. For your next starter, why not give it a try?

For Starters. Flatulence, Flasks and Fermcap® S

There are many benefits to making a yeast starter, and a plethora of threads on this forum discussing their merits and the techniques used to make them. It was through my involvement in one such thread I discovered that some people consider making a starter in an erlenmeyer to be potentially dangerous. I hold the view that with correct materials and methods, making a starter directly in the flask is arguably the simplest and most sanitary method one can employ. The purpose of this article is to illustrate this straightforward process, whilst highlighting some important steps along the way eliminating any messy or potentially injurious errors. As with any task, having the right tools for the job is imperative. Lets look at whats needed.

A lab-grade borosilicate flask

These are readily available from an array of reputable homebrew and laboratory supply stores and come in a variety of sizes. From personal experience (and much to my chagrin) owning a trifecta of flasks in 1, 2, and 5 liter sizes, I would advise against buying one smaller than 2 liters.

A stir-bar (optional)

Using a stir plate is highly recommended. Constantly stirring the starter optimizes oxygen absorption into the wort and keeps the yeast in suspension. The result is a more rapid completion of the starter and greater yeast growth-rates.

A non-airtight stopper

During fermentation of the starter, a free in-flow of air while at the same time preventing ingress of airborne particulate is desirable. This allows an oxygen-rich, sanitary environment to be maintained inside the flask. A sanitized foam stopper or aluminum-foil will serve this purpose effectively. Airlocks are contra-indicated.

A weighing scales with gram resolution

A starter gravity approximating 1.037 is desirable. To achieve this 1g of dry malt extract is needed for every 10ml of the planned starter size.

A heat source capable of bringing the starter volume to a boil.

I imagine most folks will use their kitchen stove when making a starter. A gas stove is not required, but is arguably preferable, as any required adjustments to the intensity of the heat can be made with immediate effect.

Dry malt extract (DME)

This is an incredibly hydrophilic fine powder. It is imperative to keep it stored in a sealed container or zip-lock bag and to use it in the absence of water vapor to prevent a sticky mess from forming. Albeit an extreme example, the less than desirable results of trying to add DME to already heating water can be seen in this thread.

Water

Assuming the water is potable, tap-water is all thats required. There is no need to consider mineral or pH adjustments for a starter.

Yeast Nutrient (optional)

Yeast nutrient can be added in small amounts if there are concerns about the viability or health of the source-yeast.

Fermcap® S

This product is an emulsion of the active ingredient, dimethylpolysiloxane. This prevents foam formation by reducing surface tension. It has long been approved by the FDA and WHO for human consumption.

A thorough outline of the science supporting its safety was compiled in 1975 by The World Health Organization's International Program on Chemical Safety. In addition to being a safe and effective anti-flatulence medication, frequently given to infants, the active ingredient in Fermcap® S can be found in many foods and beverages. The effective medicinal dosages are orders of magnitude higher than the amounts used in homebrewing.

To put it bluntly, you can ingest lots of dimethylpolysiloxane to stop you from farting so much. It goes in one end and out the other unchanged. No worries.

Making the starter

1. Calculate the desired starter size and gravity

There are plenty of incredibly useful and free online tools with which to calculate starter size needed for any given batch of homebrew. I am a fan of Homebrewdad's yeast starter calculator as I like to overbuild and harvest yeast for future brews directly from the starter. The projected size of a starter will vary depending on a multitude of factors including starting gravity and volume of the batch, the planned pitch rate, and the projected viability of the yeast being used.

2. Place the flask on the weighing-scales and zero it out

Place the required weight of DME into the flask and subsequently add cool tap-water to reach the desired volume. In order to target the planned specific gravity it is important to add the DME first and then the water. If this is done in the opposite manner, i.e. water first, DME second, the volume will be larger than planned and the gravity reduced accordingly.

3. Carefully add the stir-bar

Tilt the flask and insert the bar, allowing it to gently slide down the flask-wall. I have never broken a flask, but imagine that repeatedly dropping a stir bar into one, could, at least in theory, potentially weaken the glass. Perhaps not.

4. If using yeast nutrient in the starter, now is the time to add it

Adding a stir-bar or powdered yeast nutrient to near-boiling or boiling wort is likely to cause a sudden and violent boil-over to occur. The result is a sticky mess and a potentially painful experience. DO NOT ADD ANYTHING TO THE HEATING OR BOILING WORT.

5. Add one drop of Fermcap® S to the starter

This is an incredibly useful product and is in my view indispensable if making starters in an erlenmeyer flask. One drop weighs approximately 0.05g of which only a portion is dimethylpolysiloxane.

6. Heat the starter wort

Heat the wort while occasionally swirling the flask to completely mix the DME and water.

7. Bring the starter to a boil and boil it for the desired time

It would seem there is no definitive duration for which this needs to be done. In order to render microbe-laden water water safe to drink, the United States Center for Disease Control advocates boiling for one minute. Three minutes is recommended above an altitude of 6,500 feet. Boiling for one minute will sanitize water killing the vast majority of water-borne pathogens. Is this boil duration applicable to sanitizing a starter wort and flask? Ill let the reader decide. I boil my starter for 10 minutes but have no good basis for why. I just let it boil as I do other things.

8. Cool the starter

This can be easily and safely done by taking the flask off the heat, placing a sanitized foam stopper or aluminum-foil and immediately immersing the flask in cold water. A lab-grade borosilicate flask is designed with much greater temperature swings in mind.

9. Add Yeast to the starter wort

Once cooled, remove the stopper and pitch the yeast. Star san or any no-rinse sanitizer can be used to sanitize the outside of the yeast pack/vial or jar prior to pitching. Replace the sanitized sponge stopper once yeast has been added to the starter.

10. Allow the starter to ferment to completion

I usually allow 48 hours for this to occur. If using a stir-plate, this is in all likelihood far more time than is needed.

11. Chill the starter

I routinely chill a starter in the refrigerator for 3-4 days prior to using it. This allows ample time for the majority of yeast strains to flocculate and form a dense layer of yeast in the bottom of the flask. This is particularly important with large starters where adding excessive volumes of spent starter-wort could have an impact on the characteristics of the final beer.

12. Decant wort and pitch yeast

On brew-day, decant the spent wort and pitch the yeast. To prevent stressing the yeast it is desirable to have the yeast and wort at similar temperatures. The wort is cooled to a temperature slightly below that at which initial fermentation will occur and the yeast removed from the refrigerator a few hours prior to pitching with this goal in mind. Differing opinions on pitching temperature exist and I am certainly no authority on the topic. This is the method I favor.

Making a starter in an Erlenmeyer flask is simple, hassle free and can be completed while doing other things. I usually make my starters while cooking dinner on Monday evenings in preparation for a weekend brew. By eliminating the risk of boil-overs, the process becomes entirely uneventful, requiring minimal oversight. For your next starter, why not give it a try?