Ok some actual data:

This malt is no longer diastatic. A mini mash of .5 hours fine grind resulted in a positive iodine test.

The color is much less than you reported @dmtaylor in your batch despite double the time in the oven.

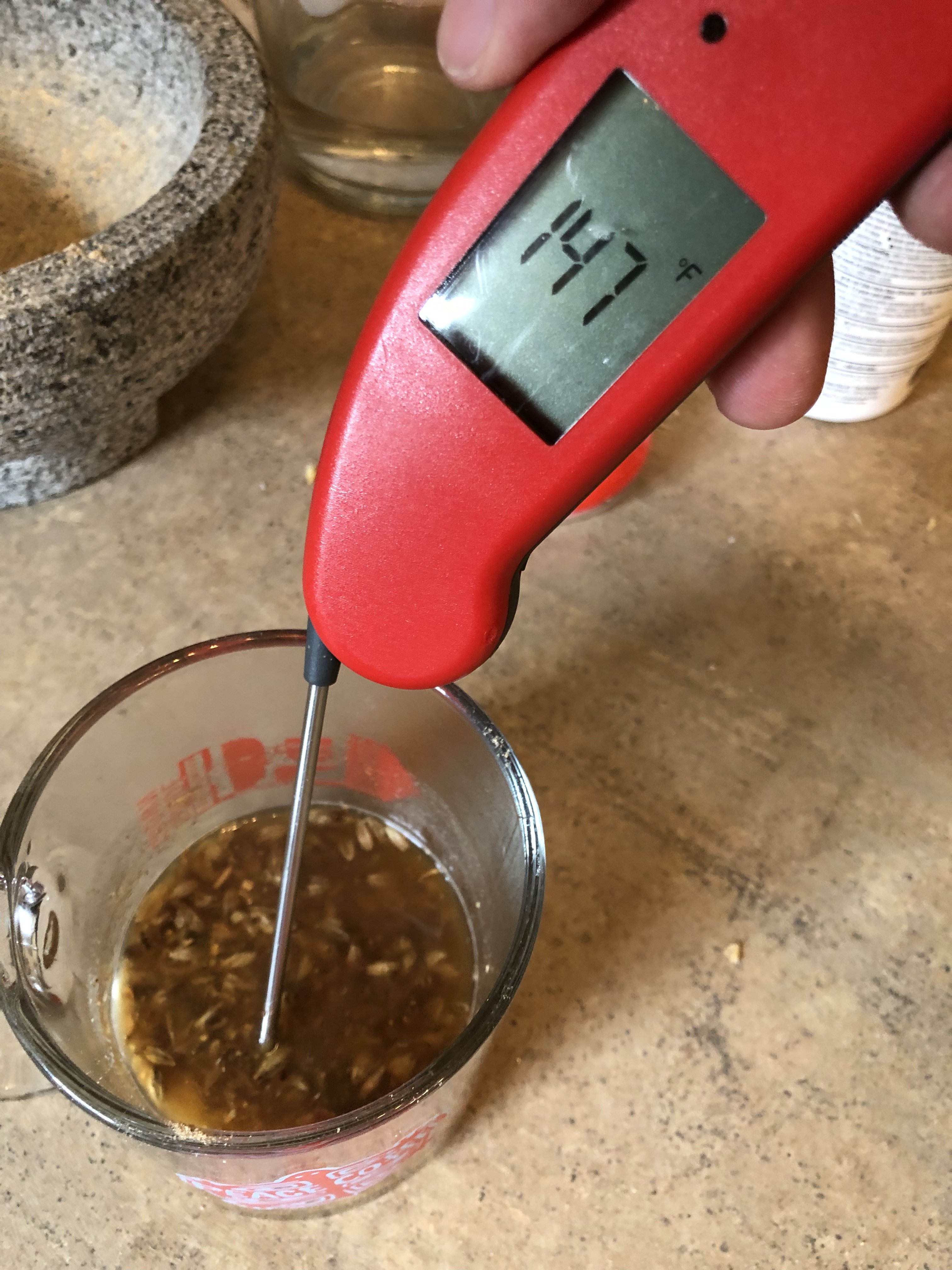

The mash pH is 5.2 using my filtered home water (not DI. residual alkalinity is 24ppm)

The mini mash smells like medium dark toast, and tastes like dry toast with almost no sweetness or Caramel flavors at all

So I'm chalking this up to the water soak before I started. I think I will prefer the results with toasting dry malt

This malt is no longer diastatic. A mini mash of .5 hours fine grind resulted in a positive iodine test.

The color is much less than you reported @dmtaylor in your batch despite double the time in the oven.

The mash pH is 5.2 using my filtered home water (not DI. residual alkalinity is 24ppm)

The mini mash smells like medium dark toast, and tastes like dry toast with almost no sweetness or Caramel flavors at all

So I'm chalking this up to the water soak before I started. I think I will prefer the results with toasting dry malt

Last edited: