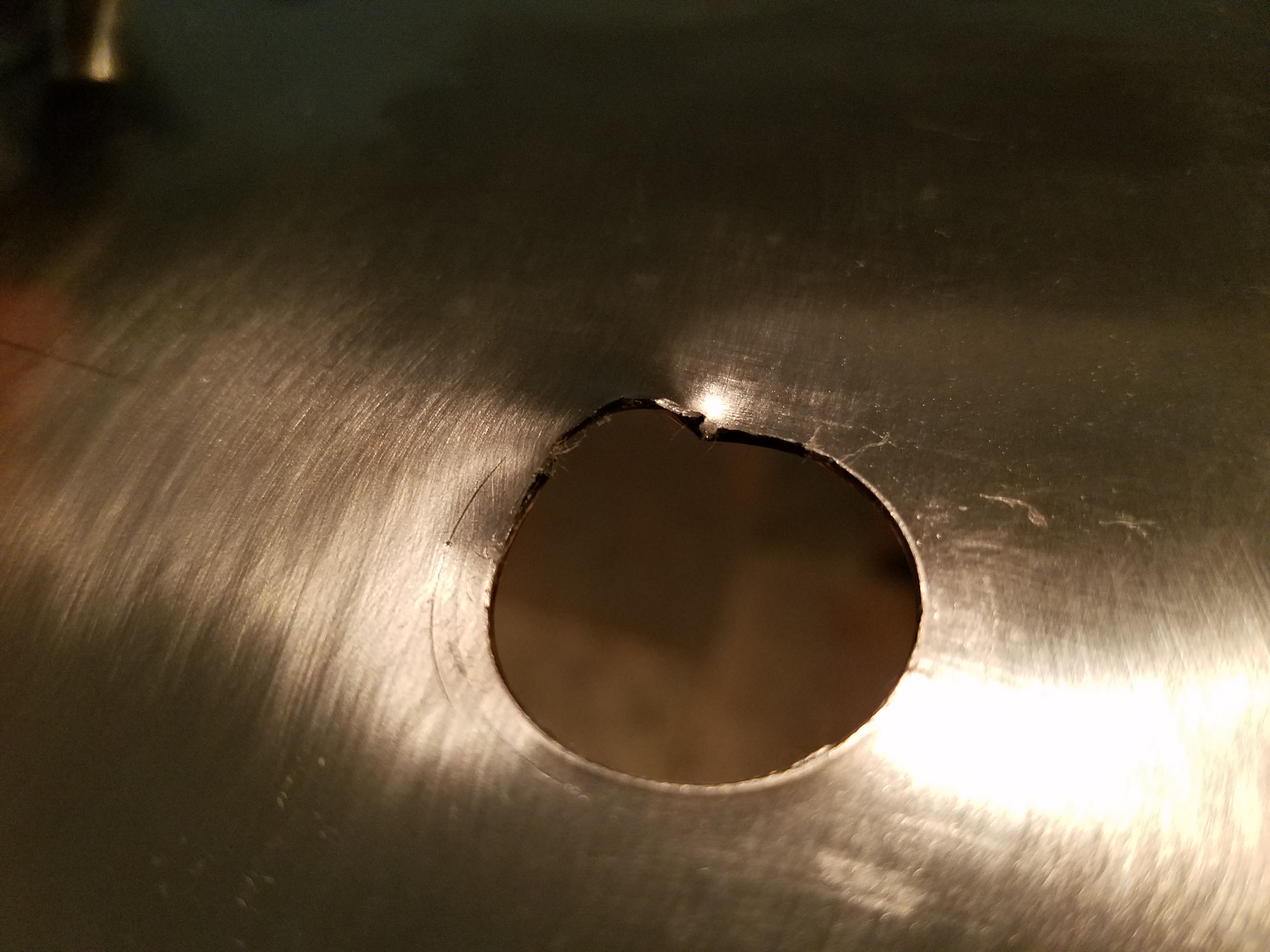

Going to put a hole for 1/2 NPT fittings in my kettle lid for eBIAB recirculation and I have a few questions. I bought 13/16 and 7/8 punches just in case but I think I will use the 7/8.

In terms of getting a clean cut, is it better to use a drill or a ratchet with a knockout punch?

If a drill is recommended, would a low speed be preferable to a high speed?

Is cutting oil recommended?

In terms of getting a clean cut, is it better to use a drill or a ratchet with a knockout punch?

If a drill is recommended, would a low speed be preferable to a high speed?

Is cutting oil recommended?