Johnman1971

Active Member

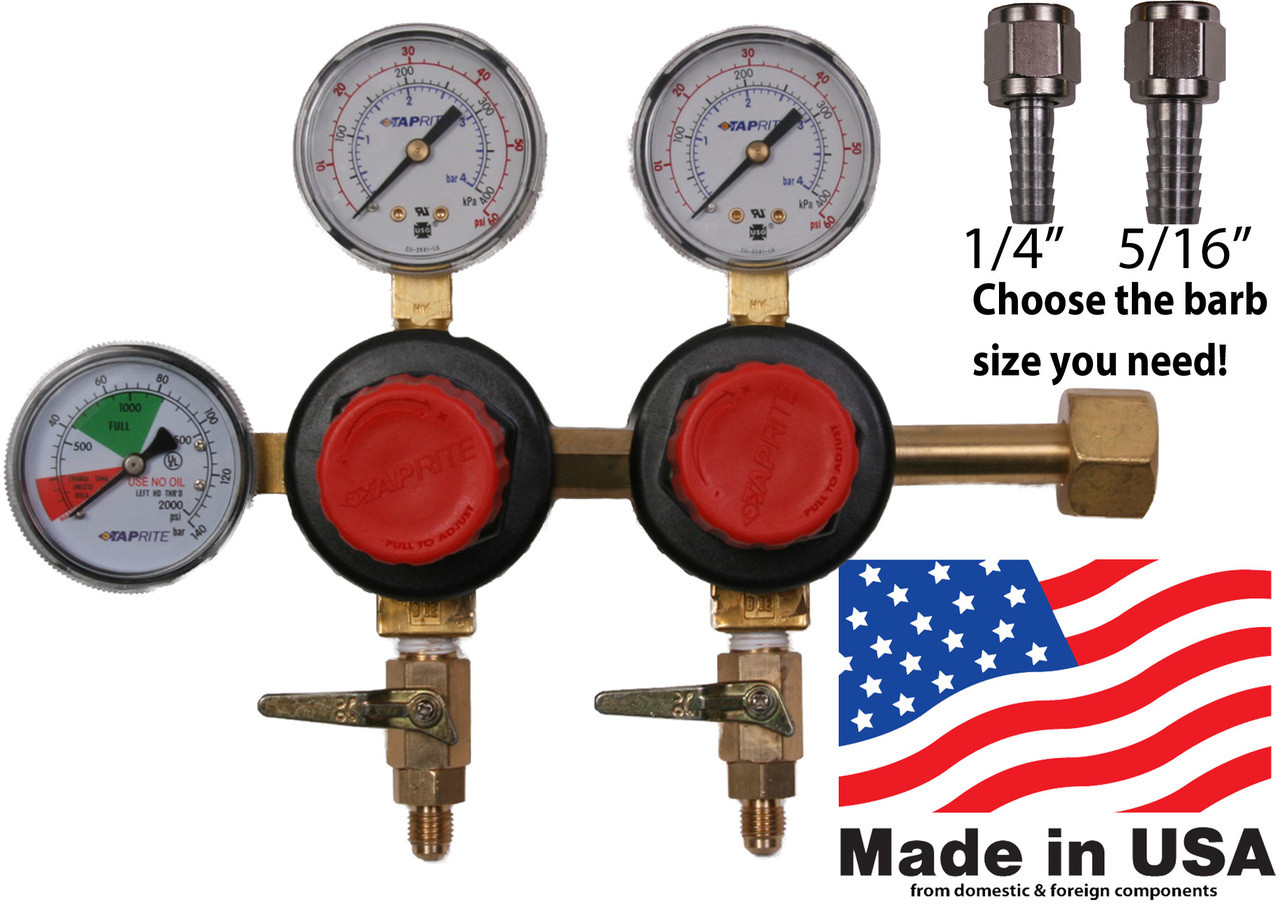

I bought a dual gauge regulator with dual outputs so that I can link 2 5 Gal kegs to my 5 Lb. CO2 tank. I have looked everywhere on the net to find out how to use the second output without it interrupting the first output. Here's where I'm at. I have one keg hooked up that I carbonated for 5 days. With the valve still open I reduced the output of CO2 from 12 to 9 (it's an imperial stout) for dispensing. Now I am ready to add my second keg, which will be a higher carbonated ale, to the second output. How do I add the CO2 to the second keg without it affecting the first keg? I don't want to add 15 Lbs. of CO2 to the first keg while carbonating the second. I realize there is a shut off valve but won't that affect the dispensing of the first beer? Maybe I just need to add the CO2 to the second keg for 5 days and not dispense the first. Any help is appreciated! :smack: