- Joined

- Jan 3, 2020

- Messages

- 2,272

- Reaction score

- 2,357

In the Beersmith equipment profile one can set up deadspace losses, loss to trub, and loss to chillers which is what sounds like has been done. Their boil off rate hasn't been stated nor the batch size.

I entered the recipe into Beersmith using my own equipment, a 3V2P keggle EHERMs. My profile uses small losses for the MT and trub however, with an 85% BH efficiency and a 6 gallon batch size, the EST OG is 1.071. At 5.5 gallons, it's 1.078. To get the Est OG to be 1.066, I had to drop BH efficiency to 70%. To hit the measured OG of 1.053, I had to drop to 55%.

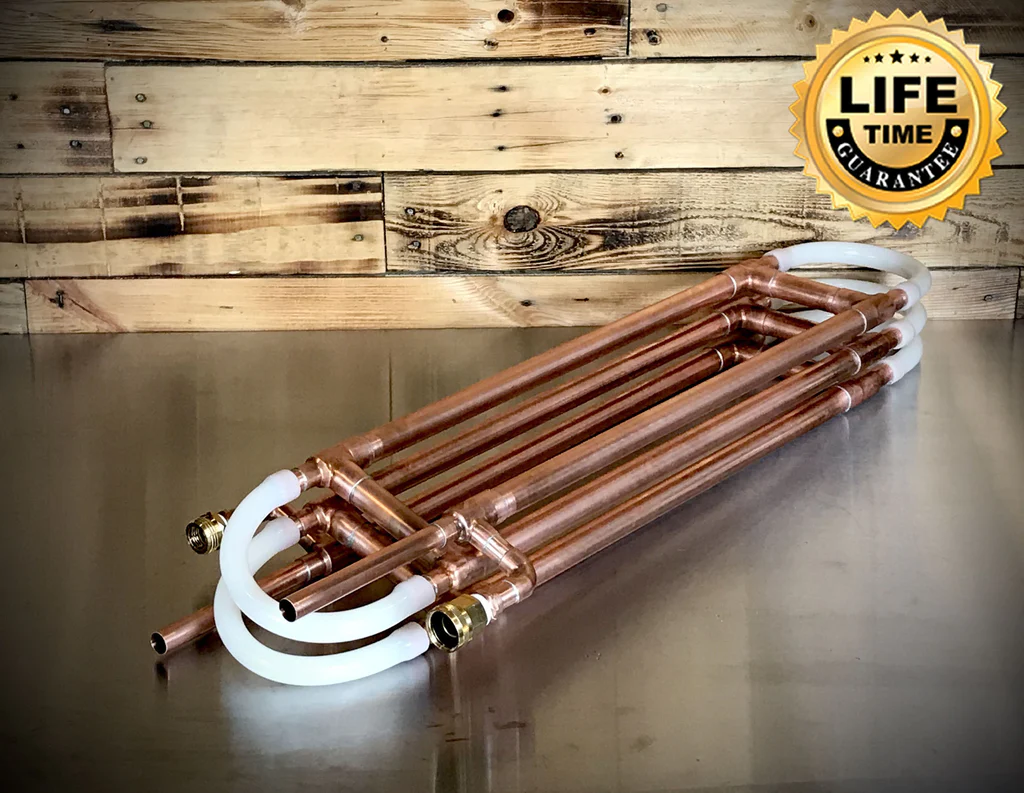

I think it would be helfpul to go over your equipment profile, letting us know what is comprising your brew rig. Then see if your thermometers are well calibrated, and what your mash and sparge process was in better detail. And your gap size on your mill and whether you set that.

I entered the recipe into Beersmith using my own equipment, a 3V2P keggle EHERMs. My profile uses small losses for the MT and trub however, with an 85% BH efficiency and a 6 gallon batch size, the EST OG is 1.071. At 5.5 gallons, it's 1.078. To get the Est OG to be 1.066, I had to drop BH efficiency to 70%. To hit the measured OG of 1.053, I had to drop to 55%.

I think it would be helfpul to go over your equipment profile, letting us know what is comprising your brew rig. Then see if your thermometers are well calibrated, and what your mash and sparge process was in better detail. And your gap size on your mill and whether you set that.

Last edited: