By now you know the story of most startup breweries. Someone with a passion for homebrewing gets a glimmer in their eye and starts daydreaming about doing it for a living. They take the plunge and go professional, but the road towards opening a brewery ends up being longer and rockier than expected.

After some trials and tribulations the doors open, pints and flights are poured, and the world is given another great craft brewery that once again began with someone who started with nothing more than a mash paddle and a dream.

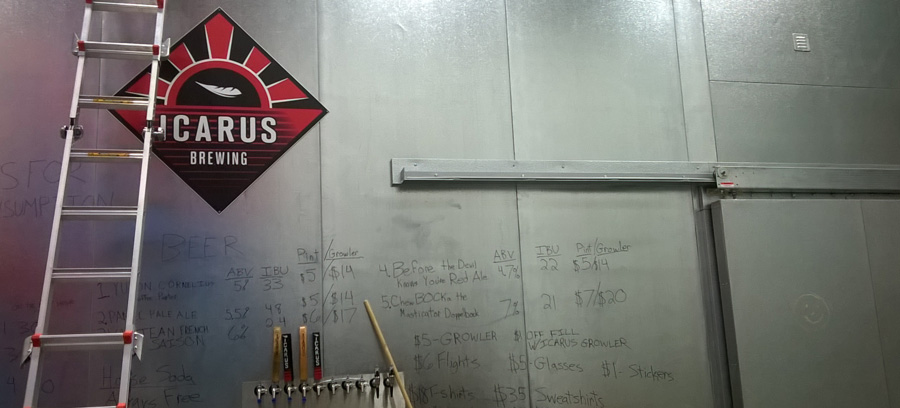

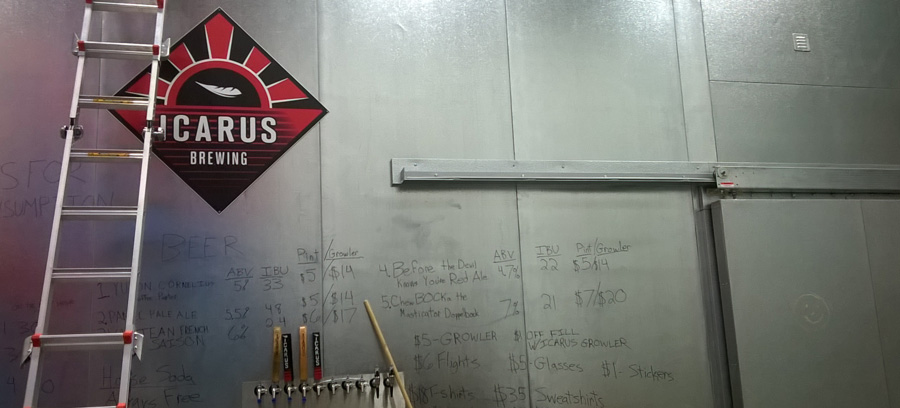

Jason Goldstein’s story is a little different. The result of his blood, sweat and tears, Lakewood, NJ’s Icarus Brewing, opened in November 2016, with the tap room opening to the public two months later. Yet he wasn’t a guy stirring wort in his garage and hoping one day that that garage would turn into a professional brewery.

Instead, it was science that led him to the mash tun.

Jason Goldstein, Icarus Brewing: I actually started in the opposite direction. I started more from the professional end. I was studying food science in college and ended up taking a few classes in food fermentation. This was long before there were as many schools offering full-on brewing degrees, so it was more making my own degree. I ended up falling in love with it more as a job. Ended up working on a bottling line. I was just a guy who threw bottles onto the bottling line, I checked for under-fills, checked for over-fills. I’d sweep the floors. Eventually I swept enough floors that they gave me a chance to clean the mash tun. Finally, after they let me clean the mash tun, they let me stand behind them while they were working on a brew day. So there was a lot of working up the ranks.

Eventually I realized it would be a long time until I could make my own batches on that scale, so that’s when I jumped into homebrewing. I jumped right into engineering my own homebrew system, my mini pilot brew house, and realized that not everything has to be scientific as on a pro level brew. When you’re homebrewing you have so much more time for creativity, so much more time for fun in brewing. You can add ingredients, you can take away ingredients, you can try brand new things that haven’t been done, and to me that’s the joy of homebrewing, and the joy of craft brewing. The fact is we’re not Sam Adams. We’re not brewing a year’s supply every time we brew, we’re trying out new things. So that’s the joy for me in homebrewing and the joy I experience today in my own brewery.

ICARUS: I’m still extremely involved in the local homebrew club. I always try to give this advice to homebrewers: take notes. Just always take notes.

One of the biggest things for professional brewers is being able to repeat a process for the same beer over and over. Even if you are creating a unique twist on a batch, at least you know what worked in a batch when you take notes. Even if you’re brewing just five gallons, even if you’re brewing extract, you want to be able to brew it again a second time because it came out delicious the first time. Or if it didn’t work out so well, you want to know why it didn’t work so well!

ICARUS: Same as on a professional level, I fell in love with consistency. Consistency to me was an electric homebrew system. For me that meant I could have the same batch going year round. Didn’t need to deal with a propane burner inside my house. I didn’t have to deal with setting up a natural gas connection. I could heat up a hot liquor tank with an electric very efficiently, and I could do the same with a boil. At first I used the electric brewery plans, built myself a nice 25-gallon setup with some slight personal modifications.

Same with the brewery. I love VFDs (Variable Frequency Drives). I love the ability to limit a pump without having to limit a valve. I was always under the impression and always taught that a beer only bubbles once, so anytime you’re adding restrictions on transferring, whether it be wort or beer in the end, a VFD is very helpful for that. Eventually I started piloting on another system, and that was a 55-gallon setup and that was just a larger version of my original electric setup. And my current setup is just a 10-barrel version of my homebrew setup.

ICARUS: I try to look at even a homebrew system with professional eyes, seeing what works on the professional end. Some things aren’t going to translate down, but at the same time the quality control stays the same, the cleaning at every scale stays the same. My homebrew fermenters were always stainless steel, I was always cleaning them with spray balls. I figured that was how I was doing it on the professional end, why would I not do it that way on the homebrew end?

ICARUS: Definitely. The biggest thing with homebrewing that I didn’t get the first time was to just have fun with it. Brewing is still half hobby, half profession to me, even though it’s my 9 to 5, or 9 to 2am, or 9 to 9, however you want to put it. The biggest part is always looking at recipes from the outside looking in. Think about what ingredients you’d like to work with. And then figure out how to go from there.

ICARUS: For the most part I normally have the idea and I can go big. I mean, I’m only on a 10-barrel system. There’s plenty of creativity I can have at this size. For example, my most recent idea was a smoked pilsner, and while I haven’t done a smoked pilsner before, I’ve done pilsners and I’ve done smoked beers. I know how it works with both.

At the same time, with my pilot batches I like to go in a different direction. I have a pilot fermenter. I’ll take a batch that I’ve done a dozen times, maybe my pale ale. I’ll pitch 10 barrels with the standard Scotch ale yeast, same as I do every single time, then I’ll take my 25-gallon fermenter and I’ll throw a Belgian ale yeast in, I’ll throw a saison yeast in, I’ll throw a lager yeast in. That’s my one-off now. Or maybe I’ll dry-hop differently. That way I’ll always have that 5% of change. That beer is now unique., Maybe it’s better, maybe it’s not, but I’m still “piloting” without having to do a full second brew day.

ICARUS: Definitely. My background is in food science, so for years it was always writing lab reports on how to create a new process or about a new chemical ingredient in a food, and it was always individual variables. You don’t want to change 1,000 things at once. For a pale ale that works, maybe next time you change one of the hops. Maybe you add wheat. Maybe instead of a California ale yeast you use another strain of yeast. One variable. Then you ask, did this make the beer better? Did it make the beer worse?

ICARUS: Yeast is huge. I have a French saison out right now and in all ways the recipe is somewhere between a pilsner and a pale ale. It’s the French saison yeast that gives it its full character. It gives it the white wine, it gives it the bubblegum that we’re going for. The yeast is the only living organism we’re introducing into this process. It has a mind of its own. It has a billion minds of its own. It really decides what the beer is going to become. That’s why some breweries go for a certain yeast strain. They each have their own characteristics and decide what that beer is going to become.

ICARUS: Extremely. One day on a professional brew system will scare a lot of people away. It’s a lot easier to clean up 40 pounds of spent grain than it is to clean up after 1,000 pounds of spent grain. Seeing the sweat that goes into a system like this, it really does open a lot of minds. You’ll see some things translate really well and homebrewing are just like professional brewing, but at the same time you’ll see some things don’t. We’re working with different cleansers, different sanitizers, we’re working with a lot of things that require more thought than on the homebrewing side. We’re also dealing with the outcome of 10 gallons of beer – which is always sad, you never want to pour 10 gallons of anything down the drain – compared to 300 or 600 gallons of beer.

ICARUS: Think outside the box. It’s what makes homebrewing what it is. It’s what makes craft brewing as great as it is. We’re not all brewing American Lagers, we’re brewing something fun. If you decide to add jalapeño into your beer, if you decide to add your local backyard picked fruits into your beer, just do it. Do it, write notes on it. Maybe you’ll create the next great thing and now you can reproduce it and it’s all your friends’ favorite beer. Maybe it’s what launches you to the professional scale. Or maybe you never brew it again!

ICARUS: Everyone has brewed drain-pours. It happens to the best of us. But at the same time, knowing what went right and what went wrong is always important, both on the homebrew scale and the pro scale.

Icarus Brewing is located in Lakewood, NJ, off Exit 90 on the Garden State Parkway. Find out more about Icarus Brewing on their website or follow them on Facebook.

After some trials and tribulations the doors open, pints and flights are poured, and the world is given another great craft brewery that once again began with someone who started with nothing more than a mash paddle and a dream.

Jason Goldstein’s story is a little different. The result of his blood, sweat and tears, Lakewood, NJ’s Icarus Brewing, opened in November 2016, with the tap room opening to the public two months later. Yet he wasn’t a guy stirring wort in his garage and hoping one day that that garage would turn into a professional brewery.

Instead, it was science that led him to the mash tun.

Homebrew Talk: Tell me a little bit about your background in homebrewing, and how you went from being a hobbyist to saying, “You know what, I think I can be doing this professionally.”

Jason Goldstein, Icarus Brewing: I actually started in the opposite direction. I started more from the professional end. I was studying food science in college and ended up taking a few classes in food fermentation. This was long before there were as many schools offering full-on brewing degrees, so it was more making my own degree. I ended up falling in love with it more as a job. Ended up working on a bottling line. I was just a guy who threw bottles onto the bottling line, I checked for under-fills, checked for over-fills. I’d sweep the floors. Eventually I swept enough floors that they gave me a chance to clean the mash tun. Finally, after they let me clean the mash tun, they let me stand behind them while they were working on a brew day. So there was a lot of working up the ranks.

Eventually I realized it would be a long time until I could make my own batches on that scale, so that’s when I jumped into homebrewing. I jumped right into engineering my own homebrew system, my mini pilot brew house, and realized that not everything has to be scientific as on a pro level brew. When you’re homebrewing you have so much more time for creativity, so much more time for fun in brewing. You can add ingredients, you can take away ingredients, you can try brand new things that haven’t been done, and to me that’s the joy of homebrewing, and the joy of craft brewing. The fact is we’re not Sam Adams. We’re not brewing a year’s supply every time we brew, we’re trying out new things. So that’s the joy for me in homebrewing and the joy I experience today in my own brewery.

HBT: That’s interesting that you got into homebrewing from the professional end. That probably gives you a slightly different perspective than the typical hobbyist. How do you think that approach changed your perspective on what homebrewing is all about?

ICARUS: I’m still extremely involved in the local homebrew club. I always try to give this advice to homebrewers: take notes. Just always take notes.

One of the biggest things for professional brewers is being able to repeat a process for the same beer over and over. Even if you are creating a unique twist on a batch, at least you know what worked in a batch when you take notes. Even if you’re brewing just five gallons, even if you’re brewing extract, you want to be able to brew it again a second time because it came out delicious the first time. Or if it didn’t work out so well, you want to know why it didn’t work so well!

HBT: So coming out of school and getting interested in homebrewing, you put together your own system. Tell us about your setup.

ICARUS: Same as on a professional level, I fell in love with consistency. Consistency to me was an electric homebrew system. For me that meant I could have the same batch going year round. Didn’t need to deal with a propane burner inside my house. I didn’t have to deal with setting up a natural gas connection. I could heat up a hot liquor tank with an electric very efficiently, and I could do the same with a boil. At first I used the electric brewery plans, built myself a nice 25-gallon setup with some slight personal modifications.

Same with the brewery. I love VFDs (Variable Frequency Drives). I love the ability to limit a pump without having to limit a valve. I was always under the impression and always taught that a beer only bubbles once, so anytime you’re adding restrictions on transferring, whether it be wort or beer in the end, a VFD is very helpful for that. Eventually I started piloting on another system, and that was a 55-gallon setup and that was just a larger version of my original electric setup. And my current setup is just a 10-barrel version of my homebrew setup.

HBT: It sounds like the principles have transferred from one to the other.

ICARUS: I try to look at even a homebrew system with professional eyes, seeing what works on the professional end. Some things aren’t going to translate down, but at the same time the quality control stays the same, the cleaning at every scale stays the same. My homebrew fermenters were always stainless steel, I was always cleaning them with spray balls. I figured that was how I was doing it on the professional end, why would I not do it that way on the homebrew end?

HBT: Did any of the other things you did when you started homebrewing carry over to the professional side? Approach, ideas, philosophies … anything.

ICARUS: Definitely. The biggest thing with homebrewing that I didn’t get the first time was to just have fun with it. Brewing is still half hobby, half profession to me, even though it’s my 9 to 5, or 9 to 2am, or 9 to 9, however you want to put it. The biggest part is always looking at recipes from the outside looking in. Think about what ingredients you’d like to work with. And then figure out how to go from there.

HBT: When you do pilot batches, what scale are you working on? Do you do homebrew scale or are you at a point where when you formulate a recipe you have a good idea of how it will turn out on the large scale and you go big right away?

ICARUS: For the most part I normally have the idea and I can go big. I mean, I’m only on a 10-barrel system. There’s plenty of creativity I can have at this size. For example, my most recent idea was a smoked pilsner, and while I haven’t done a smoked pilsner before, I’ve done pilsners and I’ve done smoked beers. I know how it works with both.

At the same time, with my pilot batches I like to go in a different direction. I have a pilot fermenter. I’ll take a batch that I’ve done a dozen times, maybe my pale ale. I’ll pitch 10 barrels with the standard Scotch ale yeast, same as I do every single time, then I’ll take my 25-gallon fermenter and I’ll throw a Belgian ale yeast in, I’ll throw a saison yeast in, I’ll throw a lager yeast in. That’s my one-off now. Or maybe I’ll dry-hop differently. That way I’ll always have that 5% of change. That beer is now unique., Maybe it’s better, maybe it’s not, but I’m still “piloting” without having to do a full second brew day.

HBT: I like that idea of 5% of change. For homebrewers, it sounds like that might be a good approach to experimentation. You take your recipe and only change one small thing, then see where it takes you from there.

ICARUS: Definitely. My background is in food science, so for years it was always writing lab reports on how to create a new process or about a new chemical ingredient in a food, and it was always individual variables. You don’t want to change 1,000 things at once. For a pale ale that works, maybe next time you change one of the hops. Maybe you add wheat. Maybe instead of a California ale yeast you use another strain of yeast. One variable. Then you ask, did this make the beer better? Did it make the beer worse?

HBT: To continue on that note, you mentioned before with your pilot batches, it’s often a matter of pitching a different type of yeast. Tell me about how significant a factor just changing the yeast can be even if the rest of the recipe is left unchanged.

ICARUS: Yeast is huge. I have a French saison out right now and in all ways the recipe is somewhere between a pilsner and a pale ale. It’s the French saison yeast that gives it its full character. It gives it the white wine, it gives it the bubblegum that we’re going for. The yeast is the only living organism we’re introducing into this process. It has a mind of its own. It has a billion minds of its own. It really decides what the beer is going to become. That’s why some breweries go for a certain yeast strain. They each have their own characteristics and decide what that beer is going to become.

HBT: For people who want to get involved in brewing professionally but they don’t necessarily want to open their own brewery – you mentioned your insane hours earlier – how important is it to have hands-on experience? Say someone wants to come in and work for you, how important is it to know they’ve gotten their hands dirty cleaning mash tuns and that sort of thing?

ICARUS: Extremely. One day on a professional brew system will scare a lot of people away. It’s a lot easier to clean up 40 pounds of spent grain than it is to clean up after 1,000 pounds of spent grain. Seeing the sweat that goes into a system like this, it really does open a lot of minds. You’ll see some things translate really well and homebrewing are just like professional brewing, but at the same time you’ll see some things don’t. We’re working with different cleansers, different sanitizers, we’re working with a lot of things that require more thought than on the homebrewing side. We’re also dealing with the outcome of 10 gallons of beer – which is always sad, you never want to pour 10 gallons of anything down the drain – compared to 300 or 600 gallons of beer.

HBT: So to wrap things up, if there was one single piece of advice you’d give to homebrewers, what would it be?

ICARUS: Think outside the box. It’s what makes homebrewing what it is. It’s what makes craft brewing as great as it is. We’re not all brewing American Lagers, we’re brewing something fun. If you decide to add jalapeño into your beer, if you decide to add your local backyard picked fruits into your beer, just do it. Do it, write notes on it. Maybe you’ll create the next great thing and now you can reproduce it and it’s all your friends’ favorite beer. Maybe it’s what launches you to the professional scale. Or maybe you never brew it again!

HBT: Yeah, maybe you brew a disaster!

ICARUS: Everyone has brewed drain-pours. It happens to the best of us. But at the same time, knowing what went right and what went wrong is always important, both on the homebrew scale and the pro scale.

Icarus Brewing is located in Lakewood, NJ, off Exit 90 on the Garden State Parkway. Find out more about Icarus Brewing on their website or follow them on Facebook.