tjash

Well-Known Member

Finally got around to testing my build last night [pics HERE, more to come] and ran into 2 problems. First, the alarm didn't work. I think I figured that out; no power supplied to terminal 13 on the PID. I corrected that, but haven't tested it yet.

Second, I put in an indicator LED with the intent of showing when the element is receiving power. So, the illuminated switch indicates power is available, and the LED should show when power is being delivered. But, the LED is staying lit all the time, whenever the contactor for the element is closed, regardless of whether or not the PID is sending power.

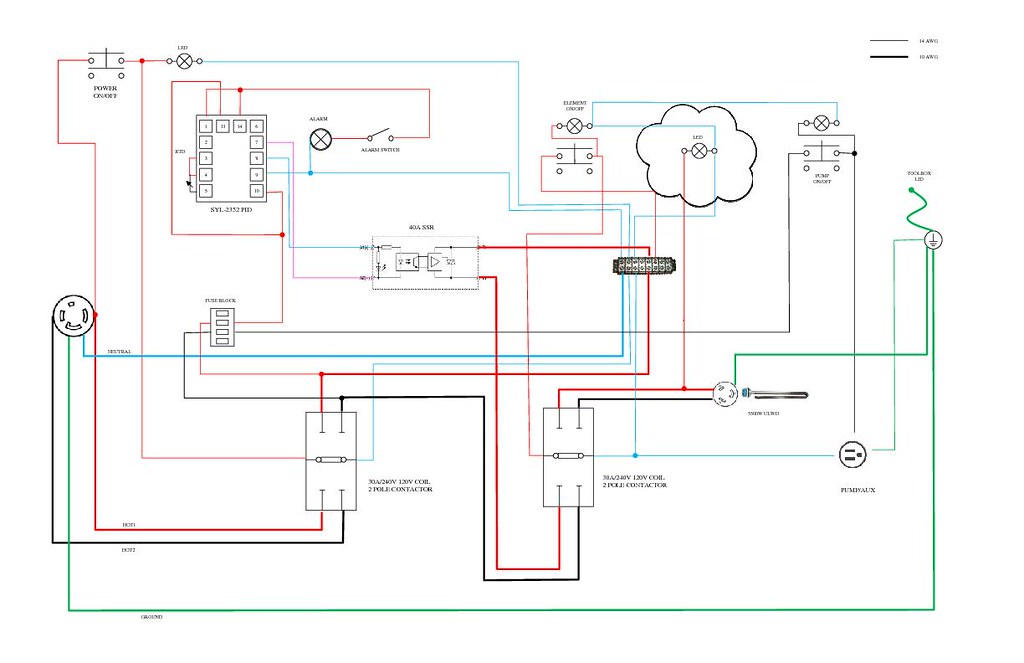

THIS is the LED I'm using. And here is my wiring diagram. The LED I'm having trouble with is highlighted with a cloud.

An electrical engineer friend at work suggested that the LED is still receiving current when the SSR isn't firing via the element. Essentially, current is "backflowing" through the element from L2 (black) to N. Is that a reasonable explanation, or is it more likely leakage from the SSR via L1 (red)?

I plan to do some testing tonight, but wanted to get some thoughts from those with more experience. Otherwise, all seems to be working well and I was able to bring about 8 gallons from 50F to 150F in under 30 mins last night!

Second, I put in an indicator LED with the intent of showing when the element is receiving power. So, the illuminated switch indicates power is available, and the LED should show when power is being delivered. But, the LED is staying lit all the time, whenever the contactor for the element is closed, regardless of whether or not the PID is sending power.

THIS is the LED I'm using. And here is my wiring diagram. The LED I'm having trouble with is highlighted with a cloud.

An electrical engineer friend at work suggested that the LED is still receiving current when the SSR isn't firing via the element. Essentially, current is "backflowing" through the element from L2 (black) to N. Is that a reasonable explanation, or is it more likely leakage from the SSR via L1 (red)?

I plan to do some testing tonight, but wanted to get some thoughts from those with more experience. Otherwise, all seems to be working well and I was able to bring about 8 gallons from 50F to 150F in under 30 mins last night!