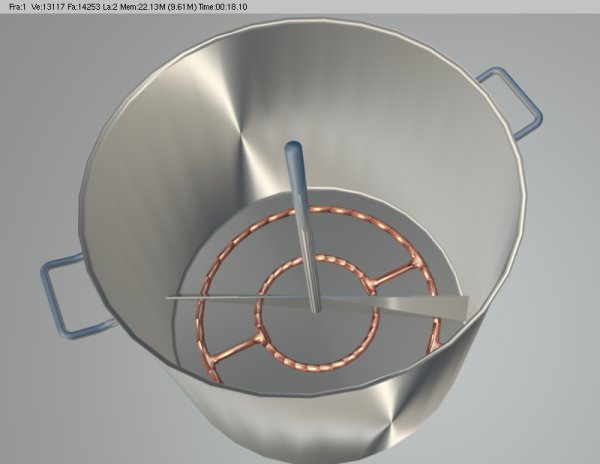

Are you fitting to an existing mash tun? If not, find a snowblower, use the auger (or 1/2 of the auger) and gearbox from it, build your mash tun to fit the o.d. of the auger. Easier than building spiral mixer from scratch, although not stainless steel.

I was actually curious when I read the first post of this thread, as to why the paddles are necessary vs. some simpler means of mixing - recirculating pump with perhaps a vortex effect to keep the entire wort moving gently without aeration...

Am I missing something?

What I see as the downside to your paddle system (or even spiral mixer) is complexity: large # of parts, need for a 3 or more legged bearing support that attaches/detaches to the top rim of the mash tun, possible belt or gear reduction from motor to axle of mixer, etc. What about a system that "agitates" the mash tun by moving it briefly counterclockwise, then clockwise, etc., and you could put some fixed vanes on the inside of the mash tun? Simpler but hopefully same end result... You might even be able to use a used washing machine for a bunch of components...